Method of producing natural gas by coupling coke oven gas and producer gas and production device

A technology for producing furnace gas and coke oven gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of unsatisfactory economic benefits of by-product hydrogen, complex process, and influence on popularization and utilization, so as to improve resource utilization value, The effect of simplifying the process and avoiding waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

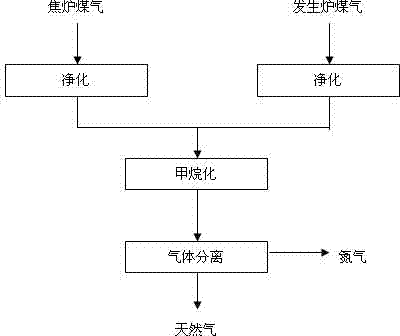

[0013] In the present invention, the purified coke oven gas and producer gas are mixed in proportion to prepare natural gas, and the differences in the components of the two gases are used to configure the two gases in accordance with the proper proportion of the methanation reaction, so that the methanation Various components in the gas can be fully reacted to produce natural gas with high purity.

[0014] Among them, coke oven gas is a by-product of coking, and its composition, content (volume percentage) and calorific value can be seen in the following table:

[0015]

[0016] Producer gas can generally be prepared from anthracite, bituminous coal, and lignite. Generally, the composition, content (volume percentage) and calorific value of producer gas prepared by different coal types can be seen in the following table:

[0017]

[0018] In the process of methanation reaction, hydrogen, carbon monoxide and carbon dioxide are mainly involved in the reaction, but many ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com