Filter bag for bag-type dust collector, bag-type dust collector and flue gas mercury removal method

A technology of bag filter and filter bag, which is applied in flue gas demercuration and filter bag field of bag filter, can solve the problems of low gas-solid contact rate, low mercury removal efficiency, uneven air distribution, etc., to save resources, The effect of high resource utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention has no special limitation on the preparation method of the mercury adsorbent, and the technical scheme for preparing metal-modified activated carbon fibers well known to those skilled in the art can be adopted.

[0045] The present invention provides the preparation method of filter bag described in above-mentioned technical solution, comprises the following steps:

[0046] The method of acupuncture is used to fix the mercury adsorbent on the base cloth, the mercury adsorbent is a metal modified activated carbon fiber, and the metal is a metal that forms an amalgam with mercury;

[0047] A filter material is covered on the base cloth fixed with the mercury adsorbent to obtain a filter bag.

[0048] The present invention adopts the acupuncture method to fix the mercury adsorbent on the base cloth, the mercury adsorbent is metal modified activated carbon fiber, and the metal is the metal that forms amalgam with mercury. The present invention has no ...

Embodiment 1

[0059] In this embodiment, mercury removal is carried out to the flue gas of the power plant in the following working conditions:

[0060] The generating set capacity of a power plant is 300MW, the average annual running time is 7000h, and the flue gas volume is 1,200,000Nm 3 / h, the original flue gas dust concentration is 15g / Nm 3 , the original flue gas mercury (Hg) concentration is 45μg / Nm 3 ; Use a bag filter to control the outlet dust concentration in the flue gas to 30mg / Nm 3 , a total of 12,000 8m long filter bags are required, each with a filter area of 3.3m 2 , the filter bag replacement cycle is three years, that is, the running time is 21000h;

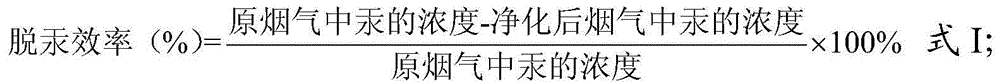

[0061] Mercury removal requirements: the concentration of mercury (Hg) in the clean flue gas is less than 3μg / Nm 3 , the mercury removal efficiency requirement is 93.3%, that is, the total amount of heavy metal mercury (Hg) in flue gas is required to be removed in one year is 352.8kg.

[0062] Activated carbon fiber l...

Embodiment 2

[0065] In this embodiment, mercury removal is carried out to the flue gas of the power plant in the following working conditions:

[0066] The generating set capacity of a power plant is 300MW, the average annual running time is 7000h, and the flue gas volume is 1,200,000Nm 3 / h, the original flue gas dust concentration is 15g / Nm 3 , the original flue gas mercury (Hg) concentration is 45μg / Nm 3 ; Use a bag filter to control the outlet dust concentration in the flue gas to 30mg / Nm 3 , a total of 12,000 8m long filter bags are required, each with a filter area of 3.3m 2 , the filter bag replacement cycle is three years, that is, the running time is 21000h;

[0067] Mercury removal requirements: the concentration of mercury (Hg) in the clean flue gas is less than 3μg / Nm 3 , the mercury removal efficiency requirement is 93.3%, that is, the total amount of heavy metal mercury (Hg) in flue gas is required to be removed in one year is 352.8kg.

[0068] Activated carbon fiber l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com