Method and device for mercury removal of flue gas

A mercury and flue gas removal technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve problems such as high operating costs, loss of activated carbon, and unfavorable comprehensive utilization of fly ash by power plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

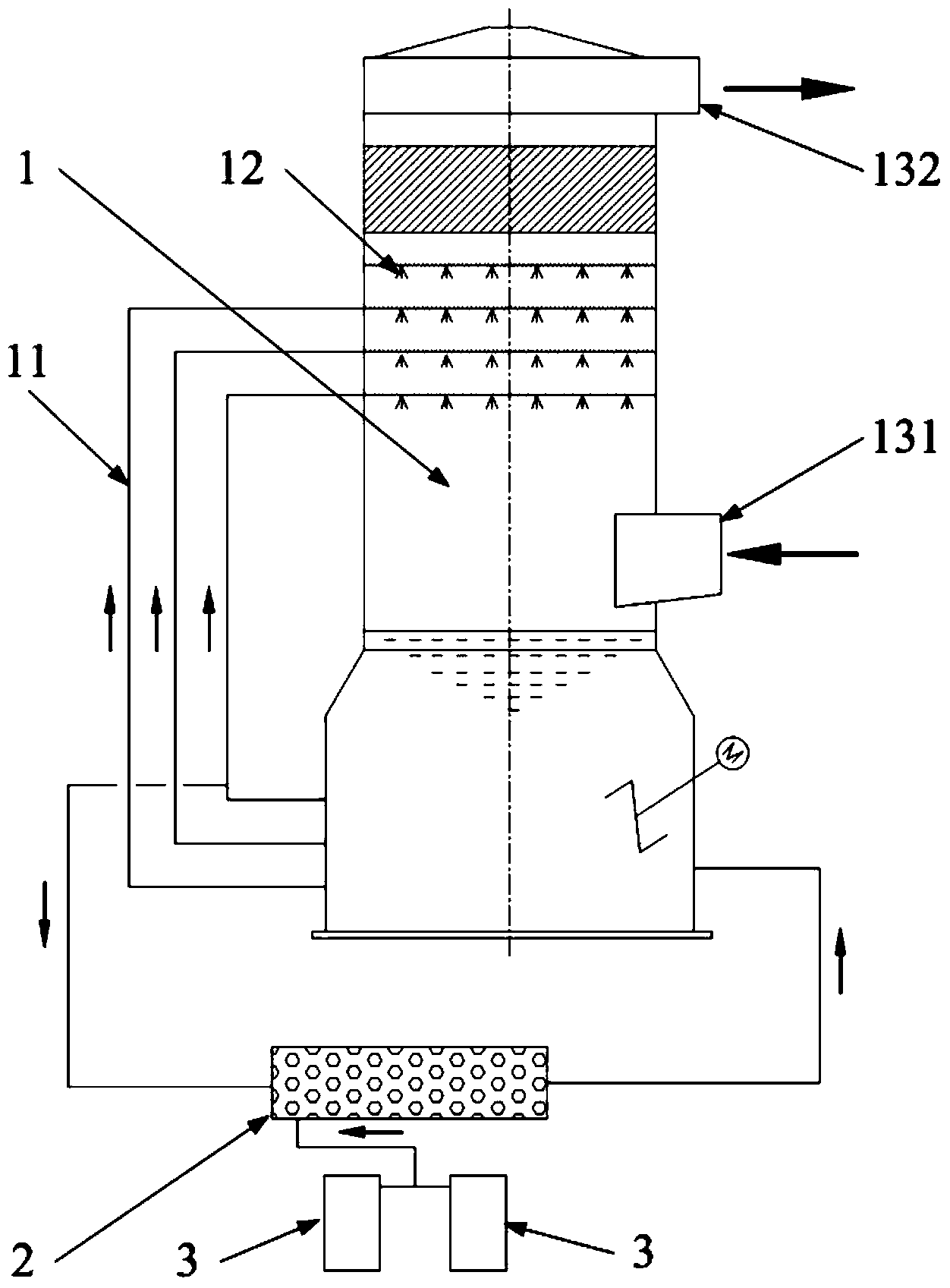

[0028] see figure 1 , is a flue gas mercury removal device provided in Embodiment 1 of the present invention, including a wet desulfurization absorption tower 1 and an activated carbon adsorption reactor 2 .

[0029] The wet desulfurization absorption tower 1 refers to the absorption tower applied to the wet desulfurization system, which is installed at the end of the flue and after the dust collector.

[0030] The wet desulfurization absorption tower 1 includes a circulation pipeline 11, a spraying part 12, and an integrated ventilation part and a liquid holding part. The vent part is located above the liquid holding part, and the vent part is provided with a smoke inlet 131 near the bottom of the vent part and a smoke outlet 132 near the top of the vent part. The spraying part 12 is located in the ventilation part, between the smoke inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com