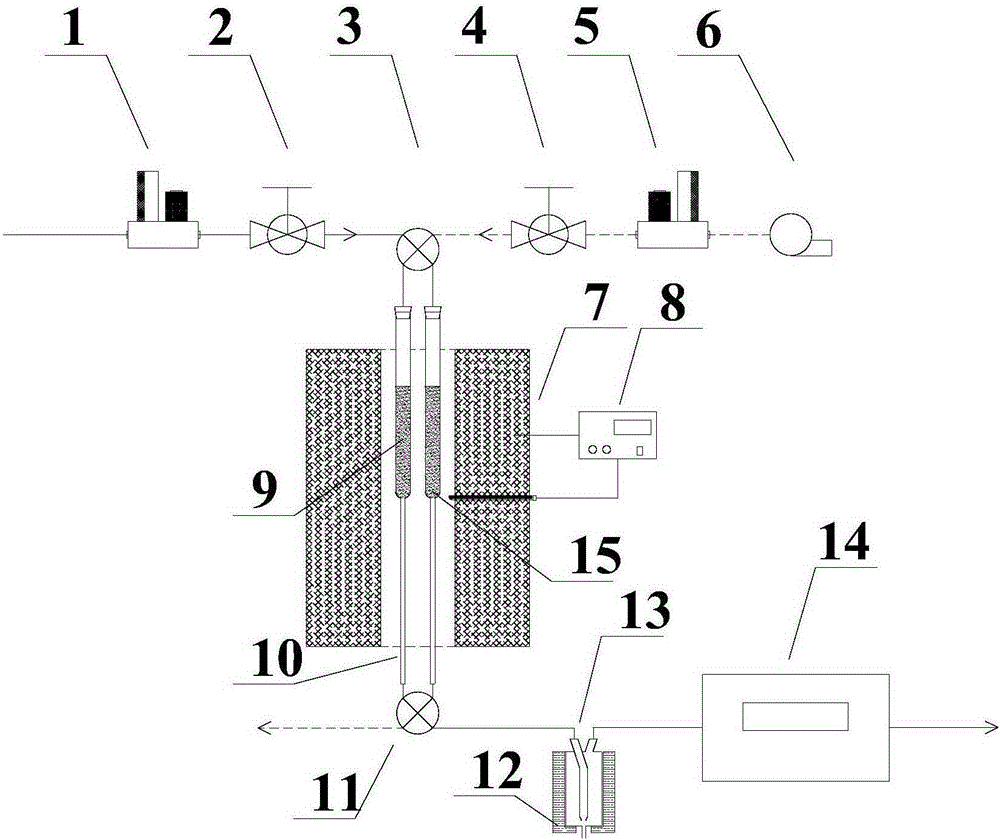

Method and device for continuous measurement of mercury in hydrocarbon-containing gas

A hydrocarbon gas and measurement device technology, which is applied in the field of mercury detection, can solve the problems of harsh gas conditions and inability to measure mercury, and achieve the effects of good applicability, elimination of the influence of hydrocarbon substances, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

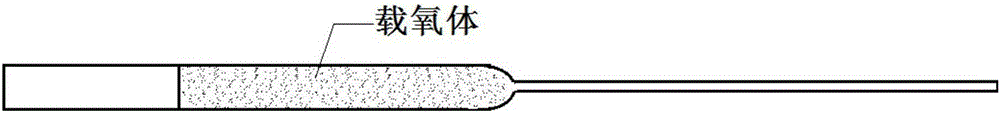

[0060] NiO is used as the oxygen carrier metal oxide, and quartz sand is used as the skeleton. The mass ratio of NiO to quartz sand is 1:9, and the particle size is 20 mesh. loading in figure 2 In the reactor, the loading length is 150 mm. When the temperature is 700°C, it reacts with pure methane gas, and the recorded reaction time is 12 minutes.

Embodiment 2

[0062] NiO is used as the oxygen carrier metal oxide, and quartz sand is used as the skeleton. The mass ratio of NiO to quartz sand is 2:8, and the particle size is 20 mesh. loading in figure 2 In the reactor, the loading length is 150mm. React with pure methane gas at a temperature of 700°C, and record the reaction time as 20 minutes.

Embodiment 3

[0064] NiO is used as the oxygen carrier metal oxide, and quartz sand is used as the skeleton. The mass ratio of NiO to quartz sand is 3:7, and the particle size is 20 mesh. loading in figure 2 In the reactor, the loading length is 150mm. When the temperature is 700°C, it reacts with pure methane gas, and the recorded reaction time is 28 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com