Ion-selective electrode flow injection analyser

A flow injection and analyzer technology, which is applied in the direction of material analysis, material analysis, and instrumentation by electromagnetic means, can solve the problems of large influence of environmental factors, inability to continuous analysis, long analysis time, etc., and achieve lower detection limit and stable potential. , the effect of small dead volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

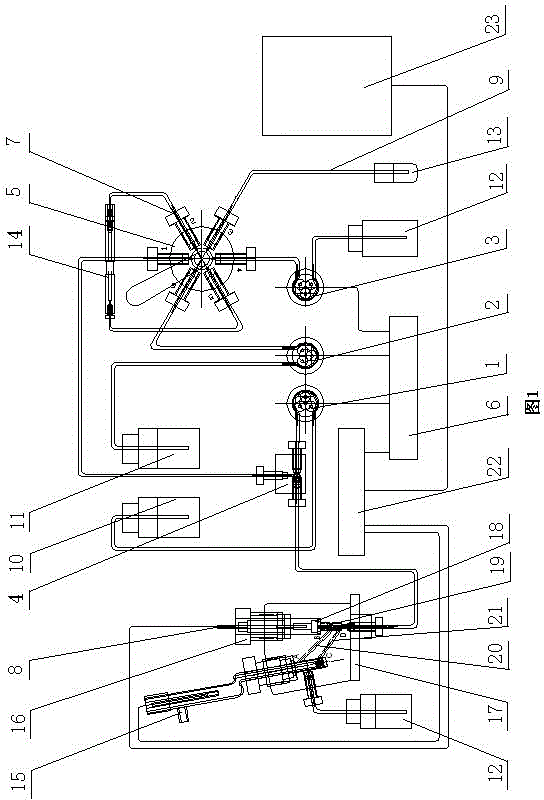

[0016] Such as figure 1 As shown, the ion selective electrode flow injection analyzer consists of a sample acquisition system, an ISE electrode system and a computer ISE software analysis system. The sample collection system consists of three peristaltic pumps 1, 2, 3, a six-way valve 4 and a separation column 14. The ISE electrode system includes a reference electrode 15, an electrode holder 17, an ISE electrode 8, a reflux tube 19 and a gravity gas-liquid separation device.

[0017] In the sample collection system, three peristaltic pumps 1, 2, and 3 are respectively connected to the control power supply 6, and each peristaltic pump is equipped with a microcatheter 7, and the three ports of the three-way valve 4 are respectively connected with a microcatheter 7. The screw is fixed, the left port is connected to the ISE electrode 8, the upper port is connected to the 1﹟ channel of the six-way valve 5, and the right port is connected to the peristaltic pump A1; the other end ...

example 2

[0019] In the ISE electrode system, the reference electrode 15 is fixed on the electrode frame 17 with a top wire 16 , the left end is fixed with a screw with a micro-catheter 7 , and connected to the waste liquid bottle 12 through the catheter 9 . The ISE electrode 8 is fixed on the electrode frame 17 with a top wire 16. The bottom end of the ISE electrode 8 is equipped with an ISE electrode film 18, and the bottom is a reflux tube 19 with a gap of 0.5 mm. The reference electrode 15 and the ISE electrode 8 pass through A-B The gravity separator composed of channel 20 and C-D channel 21 is connected, wherein the inclination angles of A-B channel 20 and C-D channel 21 are 35o and 45o respectively. The channels on both sides of the reflux pipe 19 are connected with the B and D ends of the gravity separator. The reference electrode 15 and the ISE electrode 8 are connected to a computer 23 with ISE analysis software through an analysis instrument signal interface 22 .

[0020] TI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com