Construction method and applications of water seepage channel capable of rapidly dewatering

A technology of seepage channel and rapid dehydration, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of no seepage channel, etc., to improve water filtering effect, safe operation and simple production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

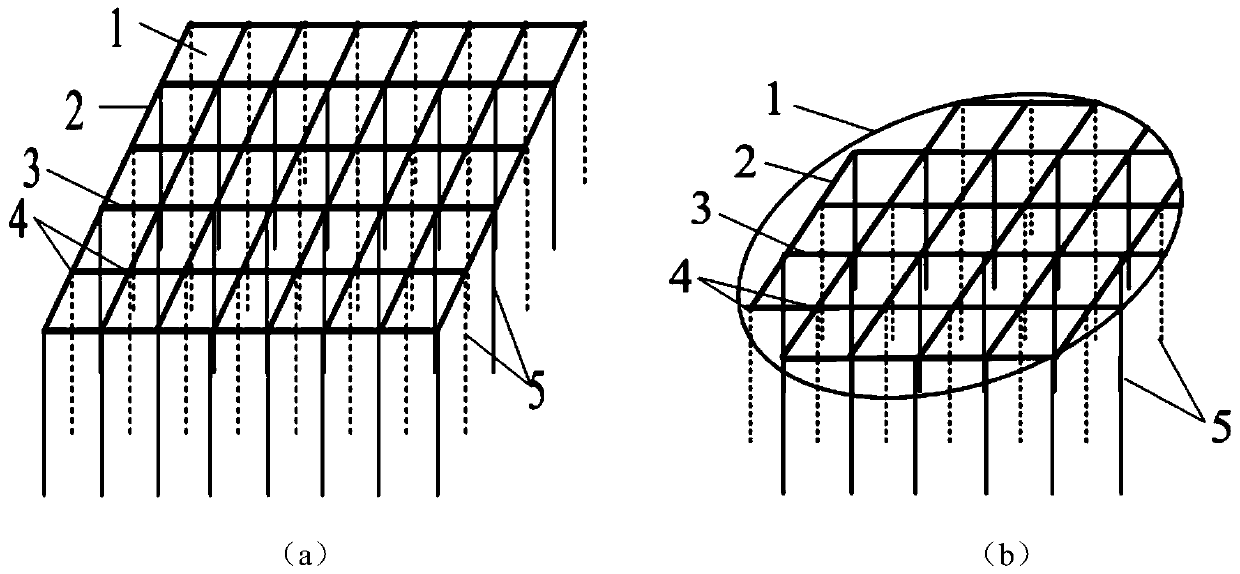

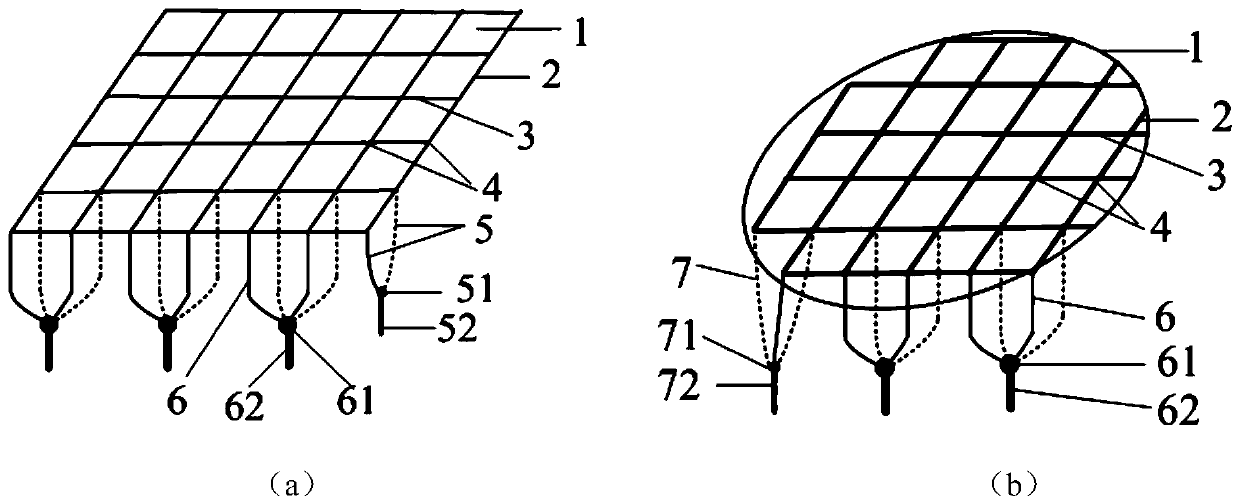

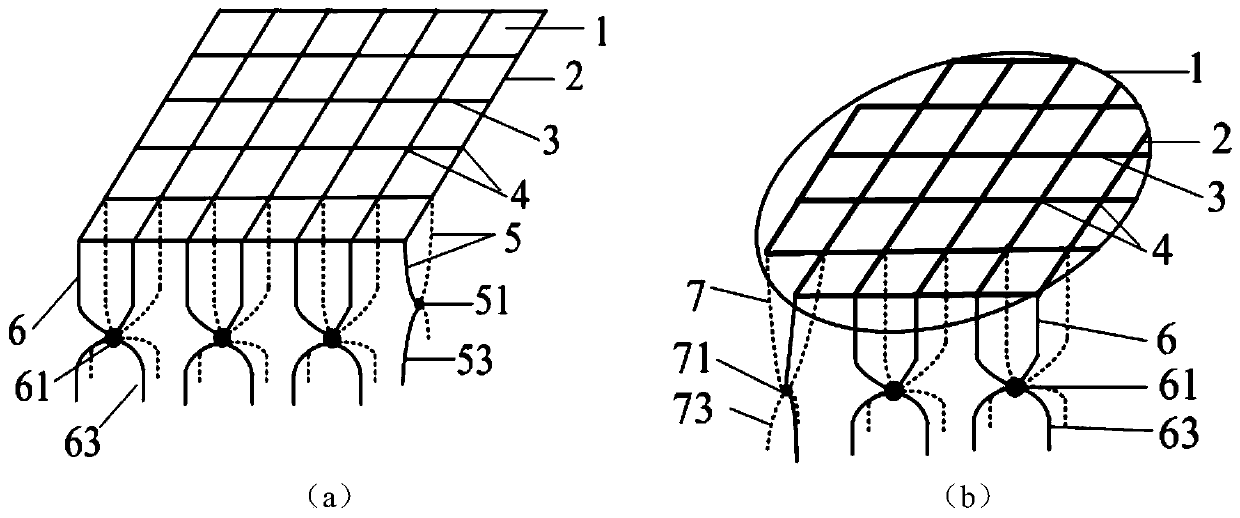

Embodiment 1

[0043] Take a plastic mesh screen with a mesh size of 5 mm and a wire diameter of 1.2 mm, and trim it to round hanging board; take 4.42g of 60S / 2, 80% skin-friendly velvet and 20% fiber velvet blended thread, cut each thread to a length of 12cm, and tie each thread to the intersection point of the warp and weft threads of the screen to naturally sag; Every two columns on the left are twisted with 4 water seepage lines adjacent to each other (3 water seepage lines are twisted at both ends), if the last column is left, twist with two water seepage lines until all are twisted to form the first layer of weft net; The second layer of weft net is twisted with 2 adjacent water seepage lines in the first column, and 4 adjacent water seepage lines (three water seepage lines at both ends of the circle) are twisted with each other from the second column; the third The layer weft mesh twisting method is the same as the first layer weft mesh; the layer height of each layer of weft mesh is...

Embodiment 2

[0047] Take a plastic mesh screen with a mesh hole of 10mm and a wire diameter of 1.0mm, and trim it into a square hanging board of 100×100; take 2.56g of 60S / 2, 80% skin-friendly velvet and 20% fiber velvet blended yarn, and cut each strand to a length of 15cm , hang each wire to the intersection point of the longitude and latitude lines of the screen, and naturally droop; from the left, every two adjacent rows of 4 water seepage threads are twisted (the last remaining 2 wires are twisted), if there is one row remaining at the end, the water seepage is done in pairs The threads are twisted until they are all twisted to form the first layer of weft net; the second layer of weft net is twisted according to two adjacent water seepage lines in the first row, and every two adjacent water seepage lines in the second row are twisted together. Twisting; the twisting method of the third layer of weft mesh is the same as that of the first layer of weft mesh; the layer height of each lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com