A rapid explosive welding device for distributing explosives

An explosive welding and rapid technology, applied in welding equipment, non-electric welding equipment, metal processing and other directions, can solve the problems of difficult to improve production efficiency, difficult to control high drug, excessive drug dosage, etc., to reduce labor intensity and save operation time. , The effect of fast and accurate dispensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

[0028] A method for rapidly distributing explosives in explosive welding, comprising the following steps:

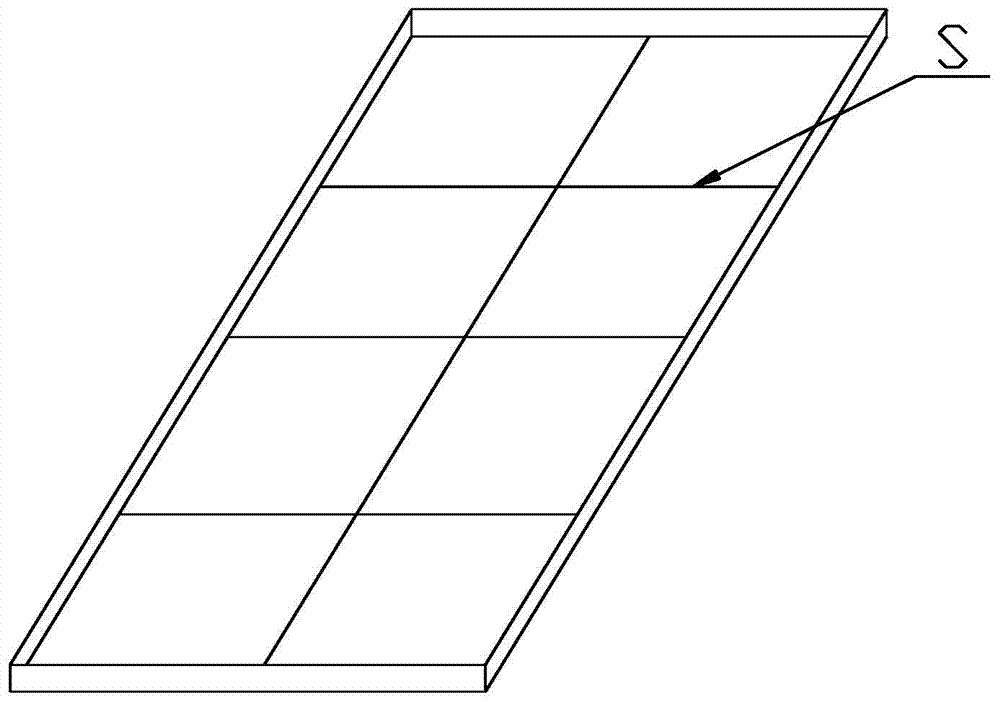

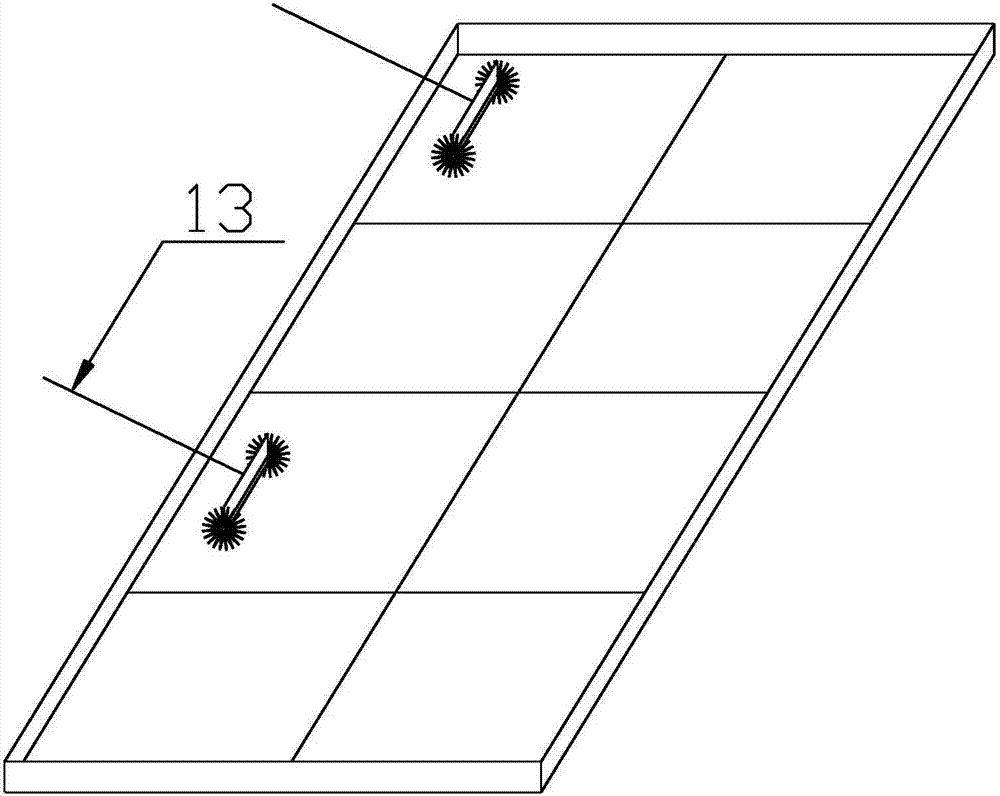

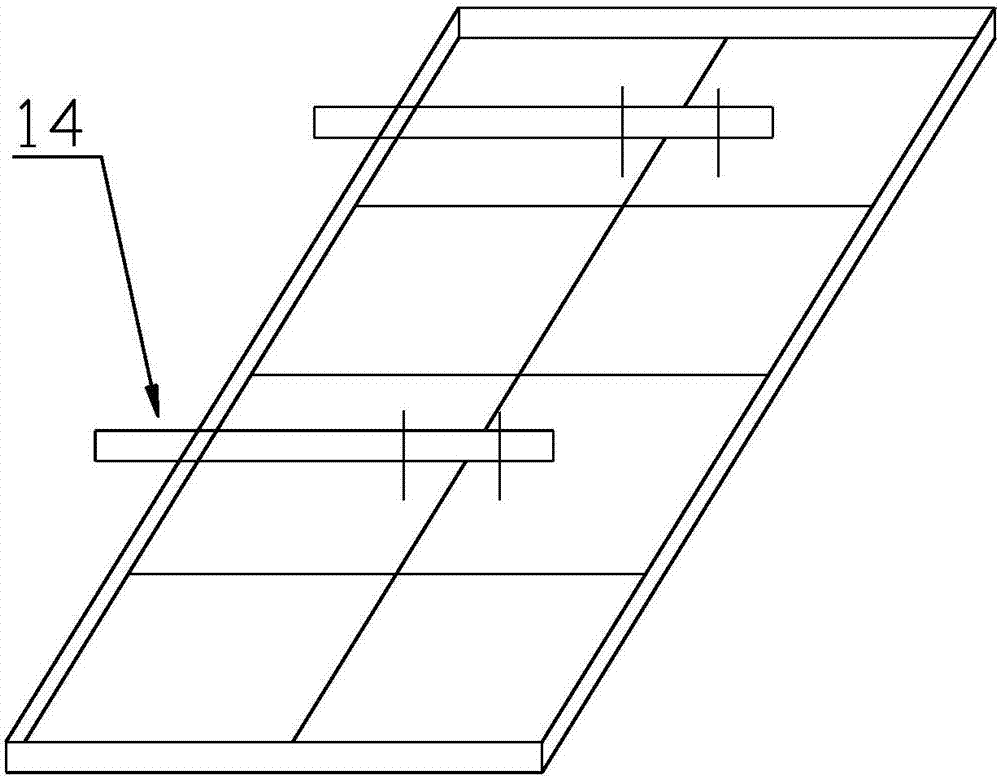

[0029] 1), drug distribution: such as figure 1 As shown, the total amount of explosives required is calculated according to the process requirements, and the explosives are evenly packed in N pockets, and the N pockets are evenly divided into group A, and the composite boards to be welded are divided according to the size of the area. The marking line is evenly divided into A block areas, and N / A bags of explosives are distributed on each area, where N is an integer divisible by A, A is an integer divisible by N, and A is greater than 1;

[0030] In the present embodiment, it is calculated that the whole board requires a total of 24 bags of explosives, then draw 8 equally divided explosive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com