A punch for machining the end face of a bearing roller

A technology of end face processing and bearing rollers, which is applied in the field of mechanical processing, can solve the problems of uneven precision and scrapping of bosses, and achieve the effects of prolonging service life, protecting molds from damage, and buffering impact forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

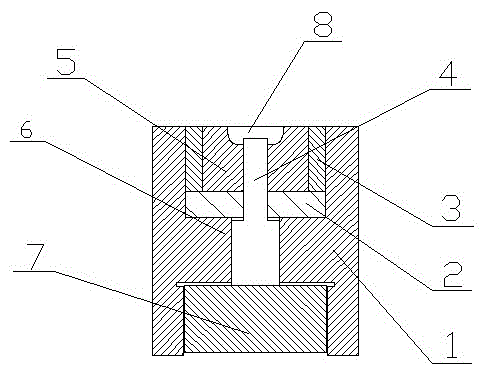

[0022] A punch for machining the end face of a bearing roller, including an outer sleeve 1, a forming core 5, a boss rod 4 and a pressing pad 7, the forming core 5 is embedded in the center hole of the outer sleeve 1, and is formed by the outer sleeve The card platform 6 provided on the inner wall of the barrel 1 is supported, and a forming groove 8 is provided on the outer end surface of the forming core 5. The boss rod 4 is set in the through hole in the center of the forming core 5, and one end thereof is set in the forming groove 8 , and the other end is connected with the pressing pad 7 provided at the end of the outer sleeve 1 .

Embodiment 2

[0024] A punch for machining the end face of a bearing roller, including an outer sleeve 1, a forming core 5, a boss rod 4 and a pressing pad 7, the forming core 5 is embedded in the center hole of the outer sleeve 1, and is formed by the outer sleeve The card platform 6 provided on the inner wall of the barrel 1 is supported, and a forming groove 8 is provided on the outer end surface of the forming core 5. The boss rod 4 is set in the through hole in the center of the forming core 5, and one end thereof is set in the forming groove 8 , the other end is connected with the pressing pad 7 provided at the end of the outer sleeve 1;

[0025] A buffer pad 2 is provided between the forming core 5 and the card table 6;

[0026] In the present invention, the boss rod 4 is composed of two cylinders with different diameters, and the diameter of one end connected to the pressing pad 7 is larger than the diameter of the other end, and the stepped surface at the junction of the two cylind...

Embodiment 3

[0028] A punch for machining the end face of a bearing roller, including an outer sleeve 1, a forming core 5, a boss rod 4 and a pressing pad 7, the forming core 5 is embedded in the center hole of the outer sleeve 1, and is formed by the outer sleeve The card platform 6 provided on the inner wall of the barrel 1 is supported, and a forming groove 8 is provided on the outer end surface of the forming core 5. The boss rod 4 is set in the through hole in the center of the forming core 5, and one end thereof is set in the forming groove 8 , the other end is connected with the pressing pad 7 provided at the end of the outer sleeve 1;

[0029] An annular prestressed sleeve 3 is provided between the forming core 5 and the inner wall of the outer sleeve 1;

[0030] A buffer pad 2 is provided between the forming core 5 and the card table 6;

[0031] In the present invention, the boss rod 4 is composed of two cylinders with different diameters, and the diameter of one end connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com