Method for simultaneously preparing polyphenols and polysaccharides from black currants

A black currant and polysaccharide technology, applied in the field of separation and purification of natural products, can solve the problems of incomplete extraction of polar active ingredients, cumbersome operation steps, waste of resources, etc., and achieve high resource utilization value, high extraction efficiency, and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

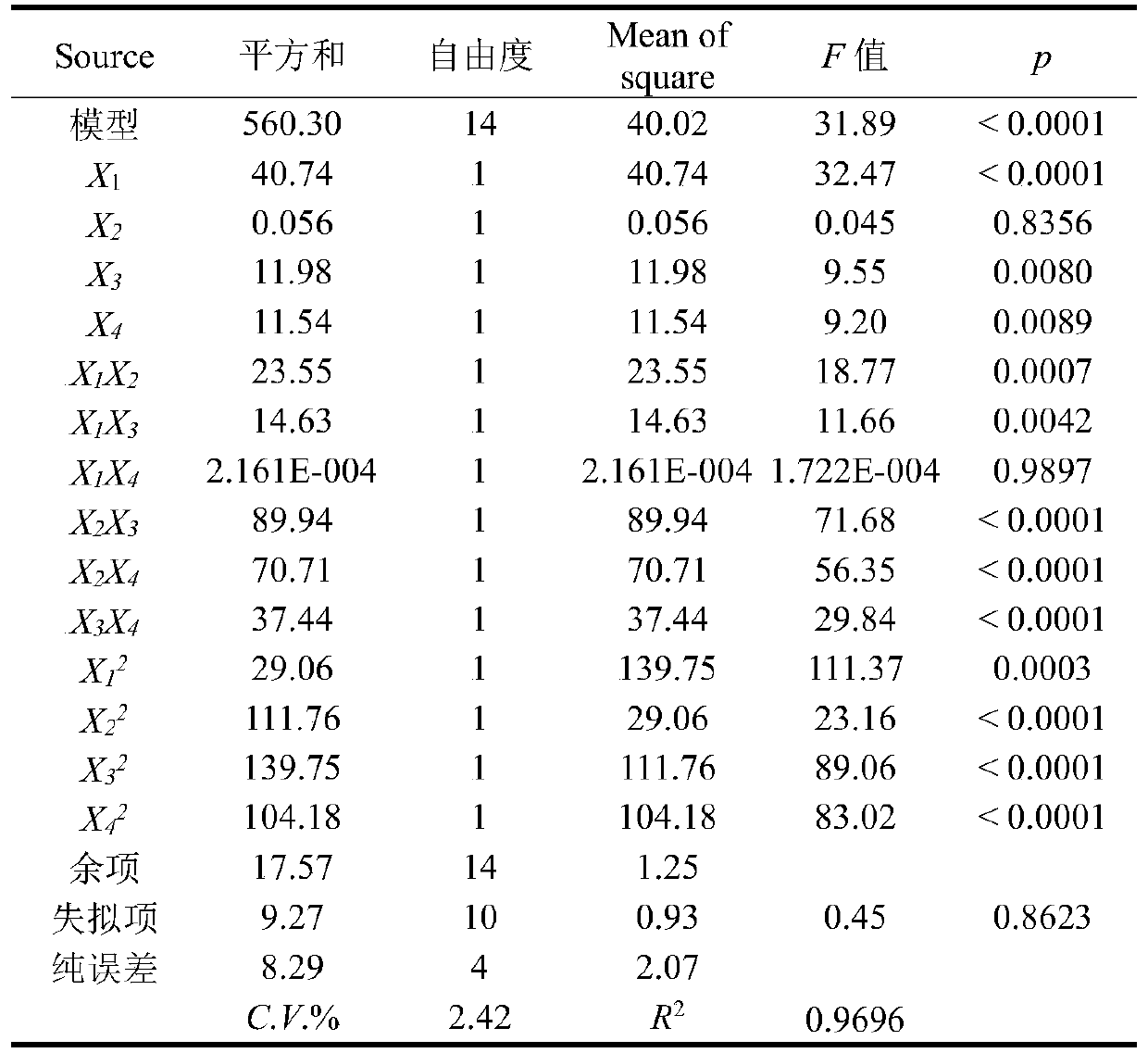

[0037] A method for simultaneously preparing black currant polyphenols and polysaccharides, the steps are as follows:

[0038] (1) Add the black currant dry powder into the aqueous two-phase system composed of 30.47% ethanol and 18.02% ammonium sulfate according to the liquid-to-solid ratio of 50:1, and treat it for 8 minutes at the extraction temperature of 60°C and the extraction power of 600W . The upper and lower phase extracts were collected by centrifugation, and the volumes were measured respectively.

[0039] (2) Take the upper phase extract, wash with ethanol to remove ammonium sulfate, concentrate and freeze-dry to obtain the upper phase crude extract.

[0040] (3) The lower phase extract was taken and dialyzed for 48 hours at room temperature to remove inorganic salts and other small molecular impurities, the dialysate was concentrated and freeze-dried to obtain the lower phase crude extract.

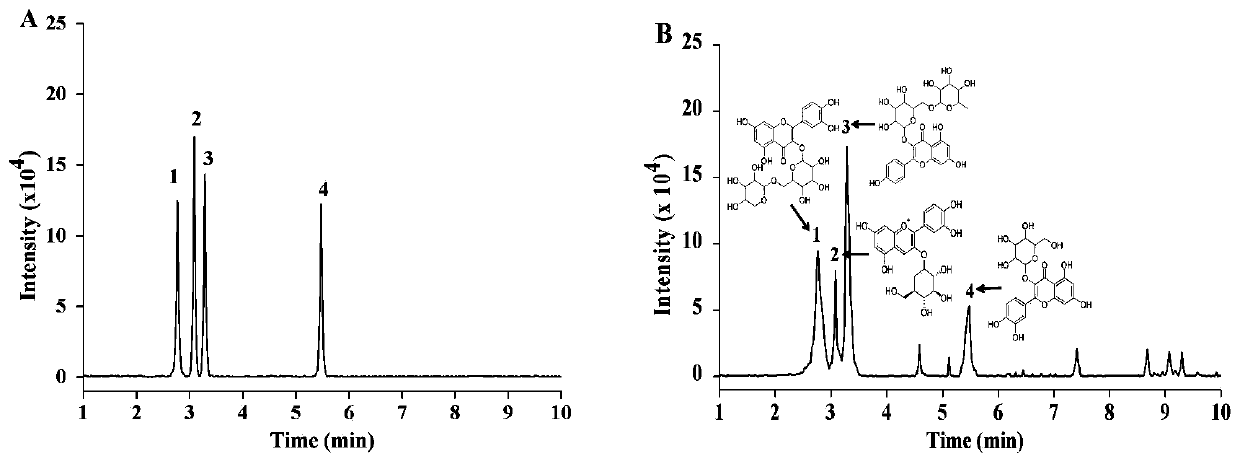

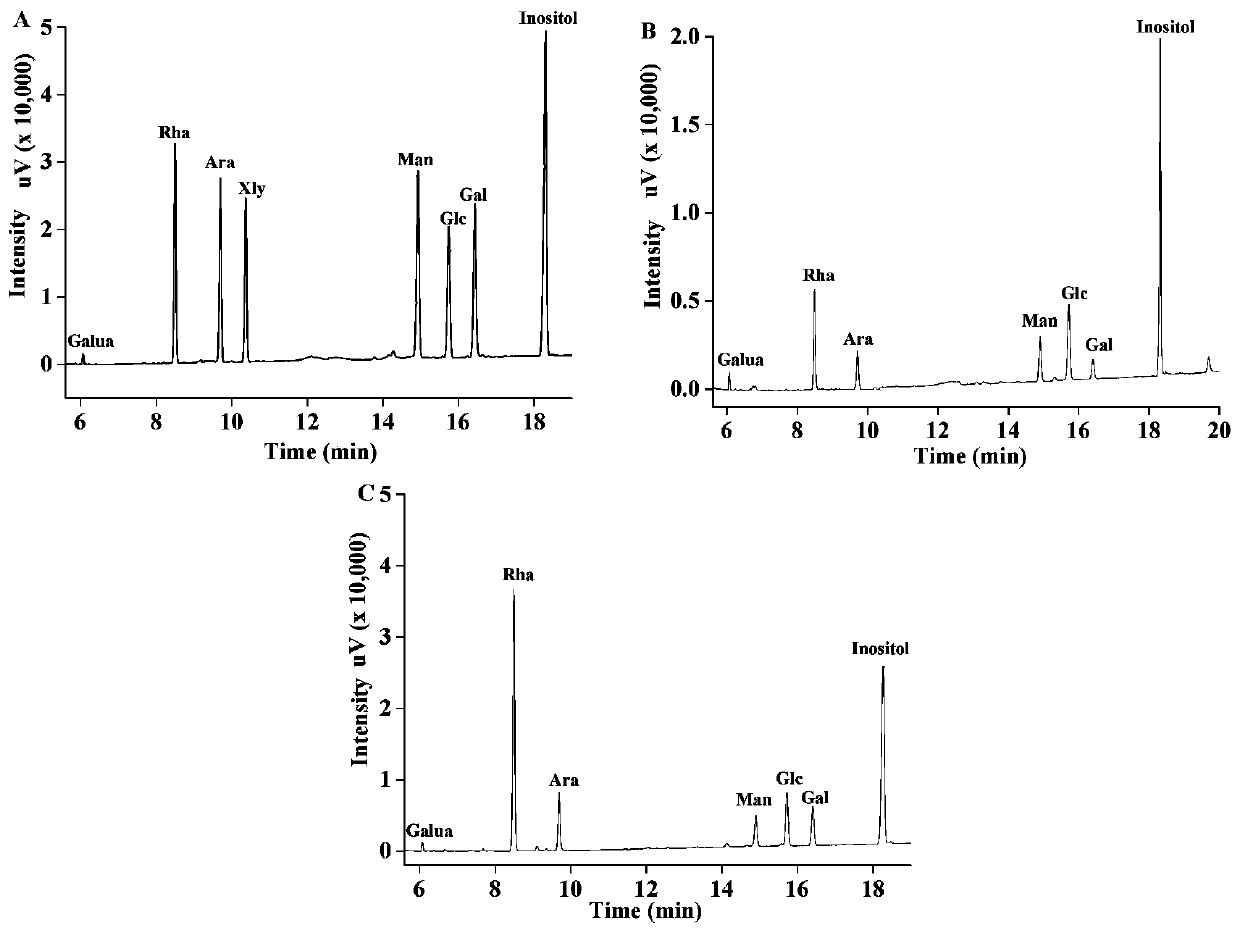

[0041] (4) Dissolve the crude extract of the upper phase, load the sam...

Embodiment 2

[0059] A method for simultaneously preparing black currant polyphenols and polysaccharides, the steps are as follows:

[0060] (1) Add the black currant dry powder into the aqueous two-phase system composed of 30.47% ethanol and 18.02% ammonium sulfate according to the liquid-to-solid ratio of 50:1, and treat it for 10 minutes at the extraction temperature of 60°C and the extraction power of 500W . The upper and lower phase extracts were collected by centrifugation, and the volumes were measured respectively.

[0061] (2) Take the upper phase extract, wash with ethanol to remove ammonium sulfate, concentrate and freeze-dry to obtain the upper phase crude extract.

[0062] (3) The lower phase extract was taken and dialyzed at room temperature for 48 hours to remove inorganic salts and other small molecular impurities, the dialysate was concentrated and freeze-dried to obtain the lower phase crude extract.

[0063] (4) Dissolve the crude extract of the upper phase, load the sa...

Embodiment 3

[0068] A method for simultaneously preparing black currant polyphenols and polysaccharides, the steps are as follows:

[0069] (1) Add the black currant dry powder into the aqueous two-phase system composed of 30.47% ethanol and 18.02% ammonium sulfate according to the liquid-to-solid ratio of 60:1, and treat it for 8 minutes at the extraction temperature of 65°C and the extraction power of 600W . The upper and lower phase extracts were collected by centrifugation, and the volumes were measured respectively.

[0070] (2) Take the upper phase extract, wash with ethanol to remove ammonium sulfate, concentrate and freeze-dry to obtain the upper phase crude extract.

[0071] (3) The lower phase extract was taken and dialyzed at room temperature for 48 hours to remove inorganic salts and other small molecular impurities, the dialysate was concentrated and freeze-dried to obtain the lower phase crude extract.

[0072] (4) Dissolve the crude extract of the upper phase, load the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com