Dyeing method suitable for dacron fabric and application thereof

A technology of polyester fiber and dyeing method, which is applied in the field of textile printing and dyeing, and can solve the problems of lengthy dyeing process of polyester fiber, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

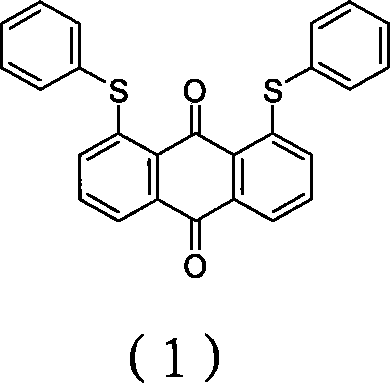

[0017] The pretreatment dyeing one-bath one-step process is as shown in accompanying drawing 1, selects pure polyester knitted fabric, and the weight is 250KG. In the high temperature and high pressure overflow dyeing machine, put dyeing water, put the polyester fabric into the dyeing machine for circulation, add 7.50KG soda ash and 7.50KG scouring agent HE0815, add 0.600KG disperse dye shown in formula (1), the total liquid volume For 2500 liters, the pH value is 10.8.

[0018]

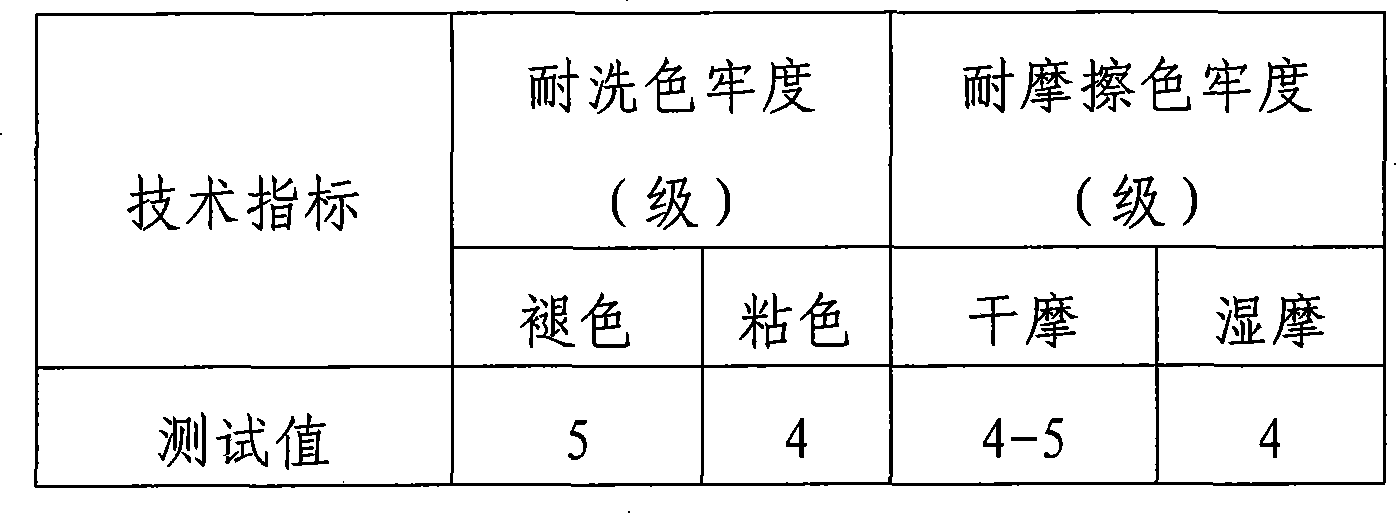

[0019] Heat up to 80°C at a heating rate of 2°C / min, then heat up to 130°C at a heating rate of 1°C / min, and keep warm for 45 minutes. Cool down to 80°C to discharge the residual liquid, wash in hot water at 80°C for 10 minutes, and finally wash in cold water at room temperature for 6 minutes, and dry the cloth to obtain a bright yellow fabric. The fabric surface is clean, the color is uniform, and the handle is smooth and soft. Fastness test results are shown in Table (1):

[0020] Table (1): D...

Embodiment 2

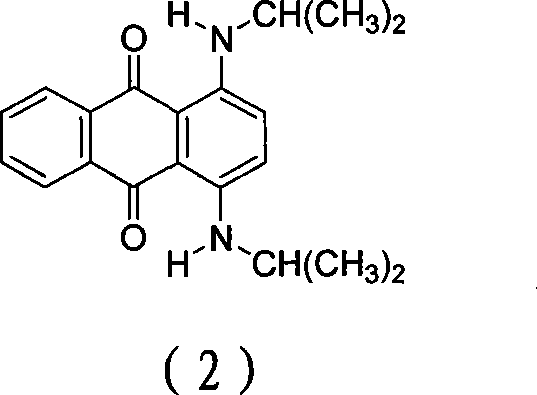

[0024] The one-bath one-step process of pretreatment dyeing is as shown in accompanying drawing 1, selects grammage 190g / m Fineness 50D pure polyester superfine fiber plain weaving cloth for use, weight is 250KG. In the high temperature and high pressure overflow dyeing machine, put dyeing water, put the polyester fabric into the dyeing machine for circulation, add 37.0KG industrial liquid alkali and 3.60KG scouring agent HE0815, add 0.600KG disperse dye shown in formula (1) and 1.000 Disperse dye shown in KG formula (2), total liquid volume is 2500 liters, and pH value is 13.04.

[0025]

[0026] Heat up to 80°C at a heating rate of 2°C / min, then heat up to 130°C at a heating rate of 1°C / min, and keep warm for 45 minutes. Cool down to 80°C to discharge the residual liquid, wash in hot water at 80°C for 10 minutes, and finally wash in cold water at room temperature for 6 minutes, then take out the cloth and dry it. Obtain bright-coloured green fabric, and fabric feel is sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com