Method for dyeing blended fabric of polysulfonamide and viscose glue

A technology for blended fabrics and dyeing methods, applied in the directions of dyeing methods, textiles and papermaking, plant fibers, etc., can solve the problems of difficult aramid sulfone/viscose blended fabric dyeing, increase the complexity of the dyeing process, and environmental pollution, and achieve dyeing. Good fastness, short dyeing time and small damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

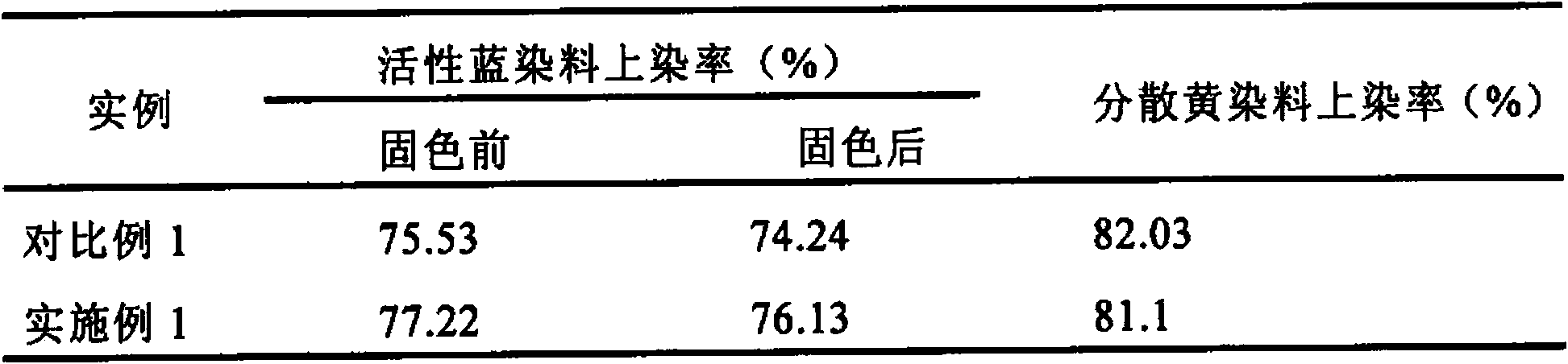

Embodiment 1

[0028] A one-bath one-step dyeing method of reactive red / disperse dyes of sulfonamide / viscose blended fabrics comprises two steps of pretreatment and dyeing.

[0029] (1) Pretreatment of sulfonamide / viscose blended fabric

[0030] Aramid fiber / viscose blended fabric → pretreatment → washing → drying → hydrogen peroxide bleaching treatment? Washing → drying.

[0031] Among them, the ratio of sulfonamide / viscose blending is 50 / 50 respectively, and the pretreatment agent and hydrogen peroxide bleaching treatment solution all use water as the solvent, and their components are as follows:

[0032] a. Pretreatment solution: sodium dodecylbenzenesulfonate 2g / L, liquor ratio, 1:30.

[0033] b. Hydrogen peroxide bleaching treatment solution: 30% hydrogen peroxide, 20g / L; oxygen bleaching stabilizer sodium silicate, 1g / L; use sodium hydroxide to adjust the pH value to 10.5-11; liquor ratio, 1:30.

[0034] Specific operation: Place the sulfonamide / viscose blended fabric in a solution a...

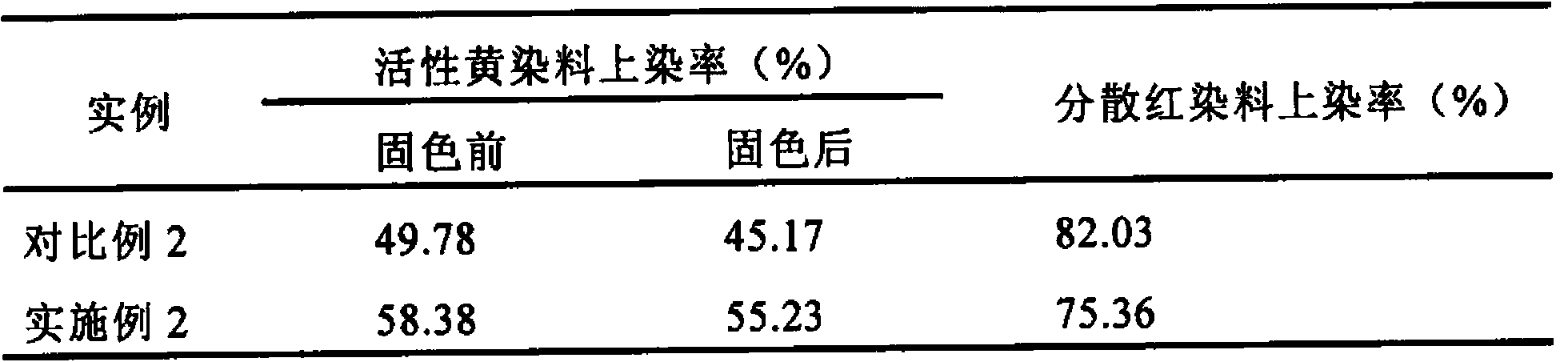

Embodiment 2

[0040] A kind of polysulfonamide / viscose blended fabric reactive / disperse dye one-bath one-step dyeing method, comprises two steps of pretreatment and dyeing,

[0041] The pretreatment steps are the same as Example 1, but the blended spinning ratio of sulfonamide / viscose is 60 / 40.

[0042] (2) One-bath and one-step dyeing of reactive yellow / disperse red dyes of sulfonamide / viscose blended fabrics

[0043] Dyeing with reactive yellow / disperse red dyes, the dye solution components are as follows: reactive yellow (Argazol NF Yellow) dye concentration is 2.4% (owf), disperse red (Artelon AQE Red) dye concentration is 3.6% (owf ), the amount of carrier acetophenone is 12g / L, the amount of sodium sulfate is 20g / L, the pH of the dyeing bath is 7, the penetrant JFC and the leveling agent TOP are both 2g / L, and the liquor ratio is 1:30.

[0044] Specific operation: immerse the sulfonamide / viscose blended fabric with a blending ratio of 60 / 40 into the prepared active yellow / disperse re...

Embodiment 3

[0055] The dyeing method of sulfonamide / viscose blended fabrics is to select neutral bath color-fixing reactive / disperse dyes for dyeing in the same bath, including the following steps:

[0056] (1) Place the sulfonamide / viscose blended fabric in a solution with surfactants added. The blending ratio of the sulfone / viscose blended fabric is 50 / 50, and the amount of surfactant is 2g / L, selected from anion Surfactant sodium alkyl sulfonate, control the temperature at 90°C, wash and dry after treatment for 1 hour, then soak in bleach solution for bleaching treatment and wash and dry, the bleach in the bleach solution is sodium silicate Hydrogen peroxide, the concentration of hydrogen peroxide is 10g / L, the concentration of sodium silicate is 1g / L, the pH value of the bleach solution is 10, and the temperature is controlled at 90°C for 45 minutes during the bleaching process;

[0057] (2) Immerse the sulfonamide / viscose blended fabric processed through step (1) in the dye solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com