One-bath one-step dyeing method for dralon/cotton blended fabric

A dyeing method and cotton blending technology, which is applied in the field of dyeing and finishing, can solve problems such as affecting dyed fabrics, reducing dye uptake rate, and reducing dispersion, so as to prevent precipitation from reaction, solve the problem of difference in dyeing conditions, and reduce environmental pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

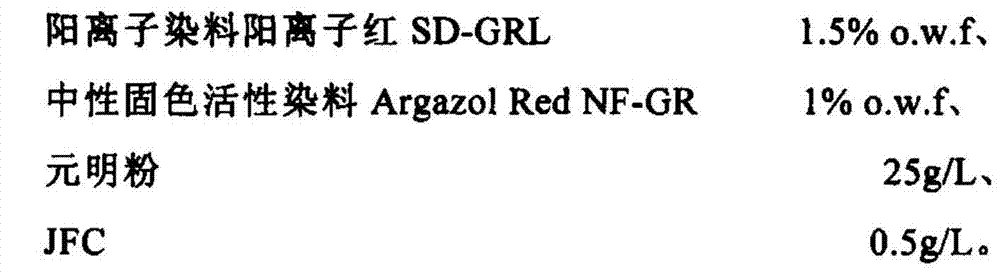

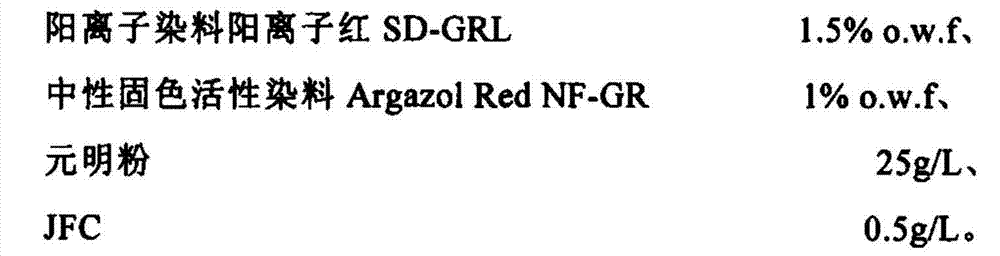

[0035] The process of dyeing cotton fibers with neutral color-fixing reactive dyes: Dissolve the reactive dyes in warm water at about 40°C to prepare a dye solution, stir well, then adjust the pH value to 7 with a buffer solution, put the fabric into the neutral salt, and level dye In the dye solution of the dyeing agent, the dyeing bath ratio is 1:30, and then the temperature is raised to 80°C at a heating rate of 2°C / min, and then to 100°C at a heating rate of 1°C / min, and kept for 60 minutes, and then washed with water and soaped , wash, tumble dry. The dye formula is as follows:

[0036] Neutral color-fixing reactive dye Argazol Red NF-3B 2.5% o.w.f,

[0037] Yuanmingfen 25g / L,

[0038] JFC 05g / L.

Embodiment 2

[0040] The process of dyeing cotton fibers with neutral color-fixing reactive dyes: Dissolve the reactive dyes in warm water at about 40°C to make a dye solution, stir well, then adjust the pH value to 7 with buffer solution, and put the fabric into the dye solution containing leveling agent In the process, the dyeing bath ratio is 1:30, and then the temperature is raised to 80°C at a heating rate of 2°C / min, and then to 100°C at a heating rate of 1°C / min, and kept for 60 minutes. After the end, washing, soaping, washing, and drying Dry. The dye formula is as follows:

[0041] Neutral color-fixing reactive dye Argazol Red NF-3B 2.5% o.w.f

[0042] JFC 0.5g / L.

Embodiment 3

[0044] The process of dyeing cotton fibers with neutral color-fixing reactive dyes: Dissolve the reactive dyes in warm water at about 40°C to prepare a dye solution, stir well, then adjust the pH value to 7 with a buffer solution, put the fabric into the neutral salt, and level dye In the dye solution of the dyeing agent, the dyeing bath ratio is 1:30, and then the temperature is raised to 80°C at a heating rate of 2°C / min, and then to 110°C at a heating rate of 1°C / min, and kept for 60 minutes, and then washed with water and soaped , wash, tumble dry. The dye formula is as follows:

[0045] Neutral color-fixing reactive dye Argazol Red NF-3B 2.5% o.w.f,

[0046] Yuanmingfen 25g / L,

[0047] JFC 0.5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com