Supercritical CO2 anhydrous yarn warp dyeing system and dyeing method thereof

A warp beam dyeing and supercritical technology, applied in the field of dyeing and finishing systems, can solve problems such as difficult to completely remove floating color, floating color affects quality, and long cycle, so as to achieve the effect of improving dyeing rate, fabric capacity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

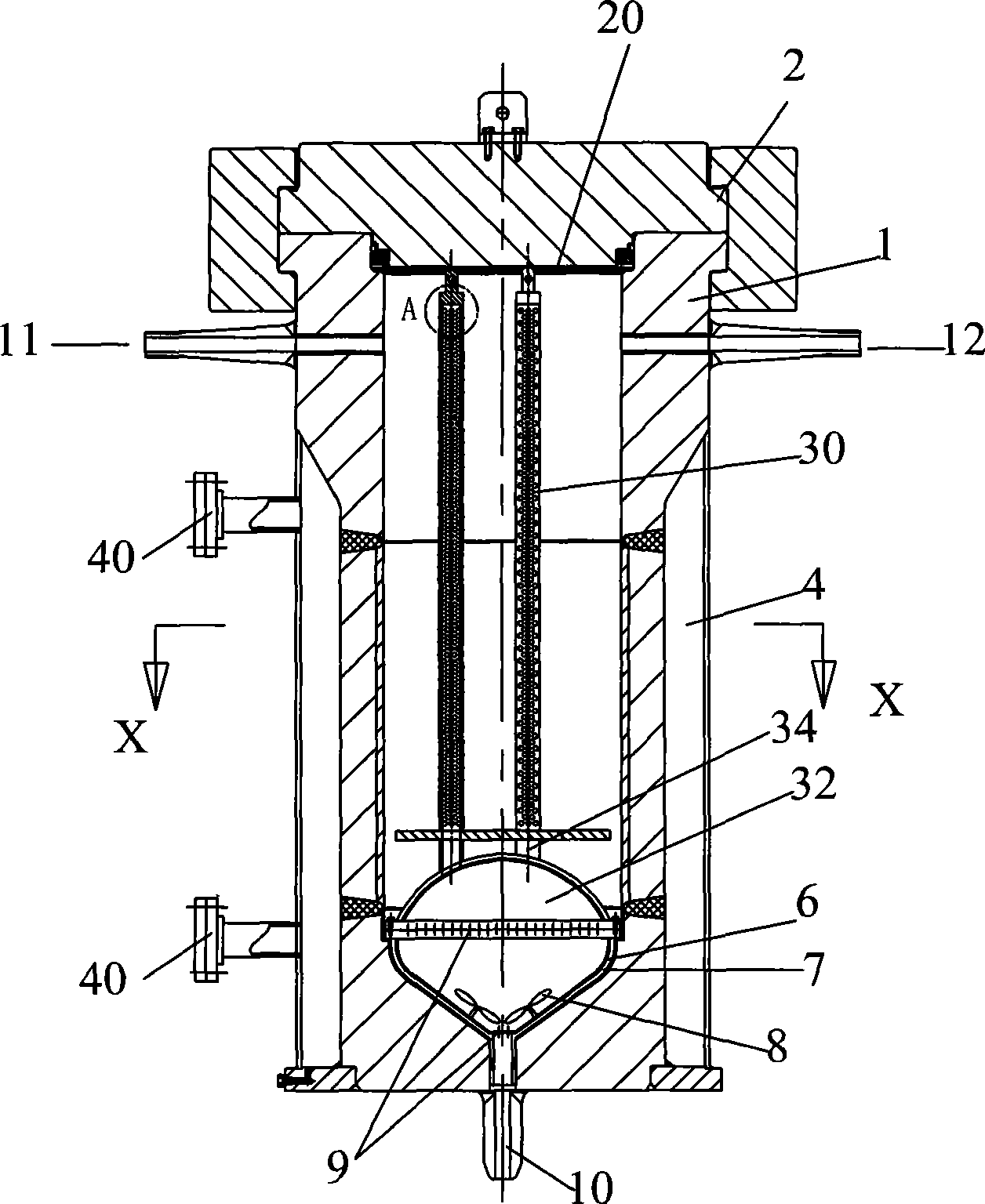

[0048] The specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

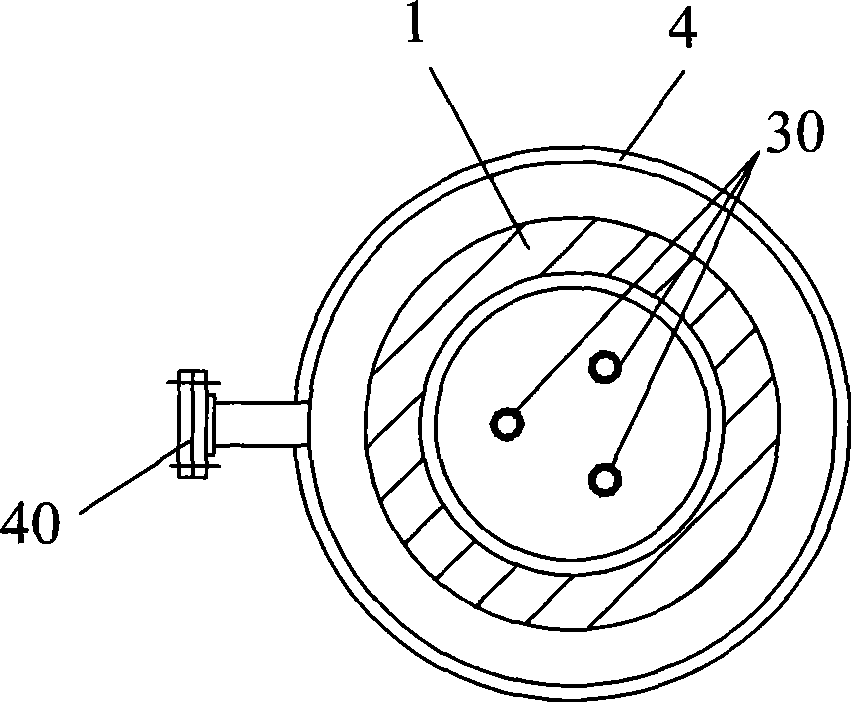

[0049] Such as figure 2 As shown, the dyeing kettle in the present invention includes a body 1 , a kettle cover 2 , a multipurpose dyeing fabric frame and a heating / cooling jacket 4 . in:

[0050] The inside of the main body 1 is hollow, and a dye vat is formed in the hollow. At the bottom of body 1 there is a supply for supercritical CO 2 The inlet 10 where the fluid enters is provided with two supercritical CO 2 Outlets 11, 12 for fluid output.

[0051] The kettle lid 2 is arranged on the top of the body 1, and a gasket 20 is arranged on its inner surface, and the kettle lid 2 and the body 1 are connected by a quick-open clamp structure (other functional structures with the same function can also be used, such as a lock , not limited to this) closing and opening, that is, when the kettle lid 2 and the body 1 are closed, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com