Method for dyeing polyester cotton on cone without reduction cleaning process

A process and bobbin technology, which is applied in the non-reduction cleaning dyeing process of polyester-cotton bobbins, can solve problems such as environmental pollution and increase production costs, and achieve the effects of exempting technological processes, saving water, electricity, and steam, and improving equipment productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described now in conjunction with accompanying drawing.

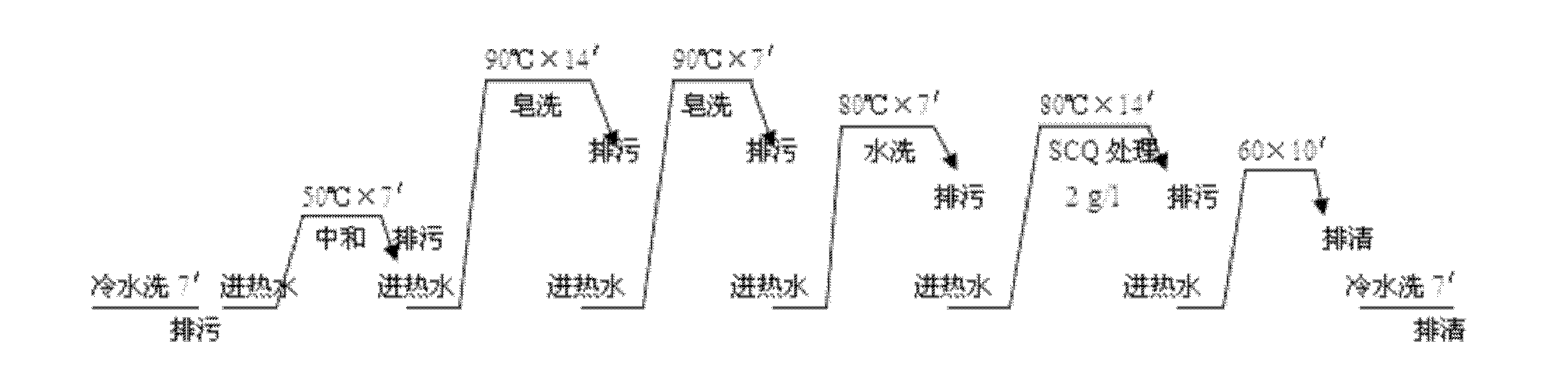

[0010] The invention includes dyeing and washing process, cotton dyeing process and post-washing process.

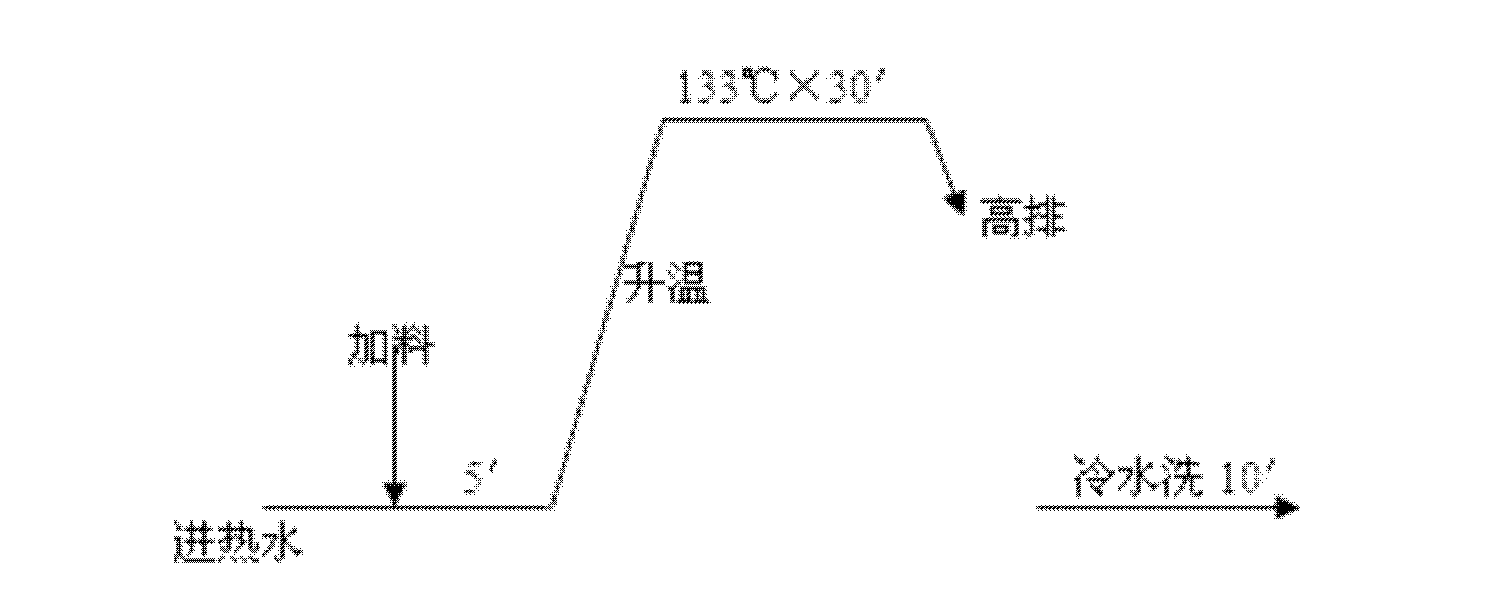

[0011] see figure 1 , the dyeing and washing process is carried out in sequence as follows: 1a, add hot water and dyes into the dye vat, and run for 5 minutes; 2a, raise the temperature in the dye vat to 133°C and maintain the temperature for 30 minutes; 3a, discharge the dye Then wash with cold water for 10 minutes.

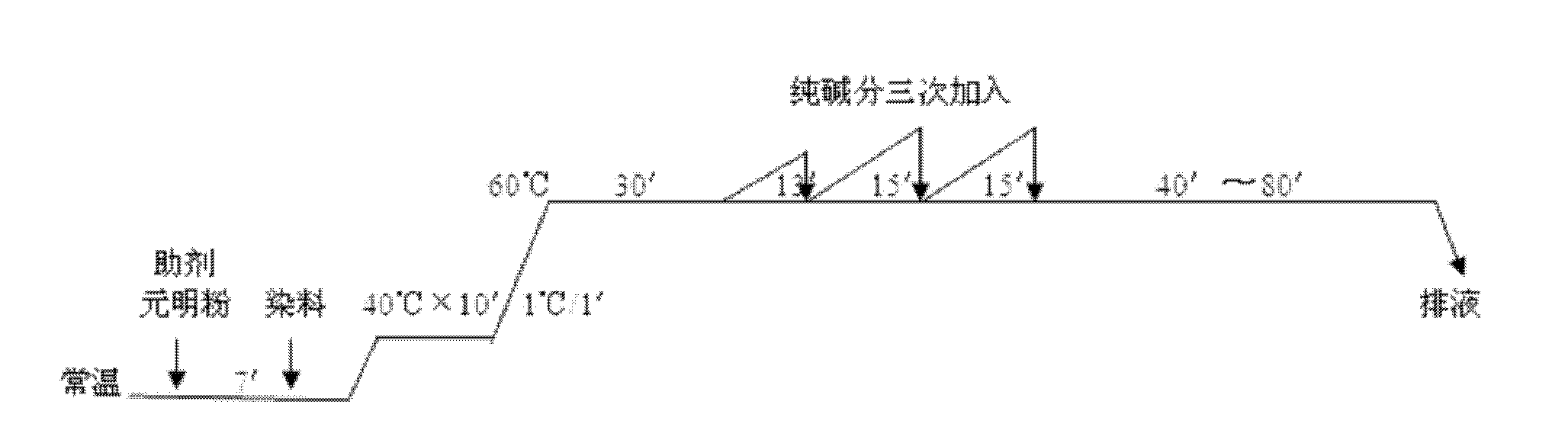

[0012] see figure 2 , the cotton dyeing process is carried out sequentially according to the following process steps: 1b, under normal temperature, add sodium sulfate Na in the dyeing vat 2 so 4 And after running for 7 minutes, add dye; 2b, increase the temperature in the dye vat to 40°C and maintain the temperature for 10 minutes; 3b, increase the temperature in the dye vat to 60°C at a speed of 1°C per minute and maintain the temperature 30 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com