Silk floss memory satin reactive dye printing process

A technology of reactive dyes and printing technology, which is applied in the field of fabric printing and dyeing processing, can solve the problems such as difficult to meet the color fastness index, and achieve the effect of good color purity and vividness, guaranteed color fastness, and high printing fixation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0017] Silk cotton memory satin gray fabric: It is made of 50% 20S silk with five satin weaves, and the plain weave of the five satins is composed of 41% 60-count cotton and 9% 750 silk wire.

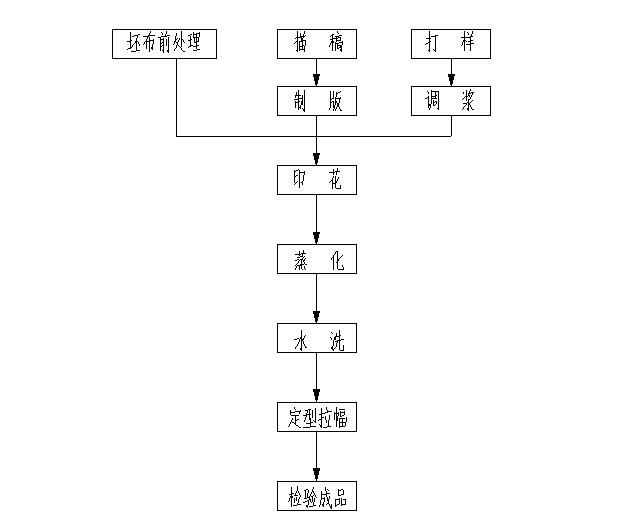

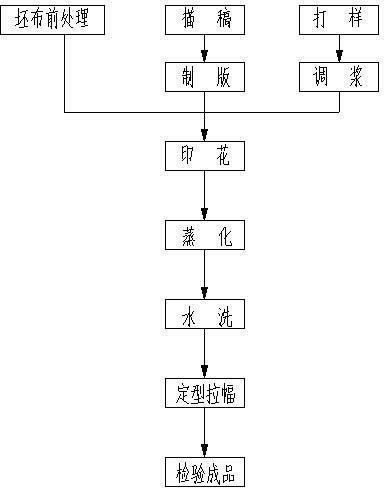

[0018] Such as figure 1 Shown, silk cotton memory satin reactive dye printing process of the present invention comprises the following processing steps:

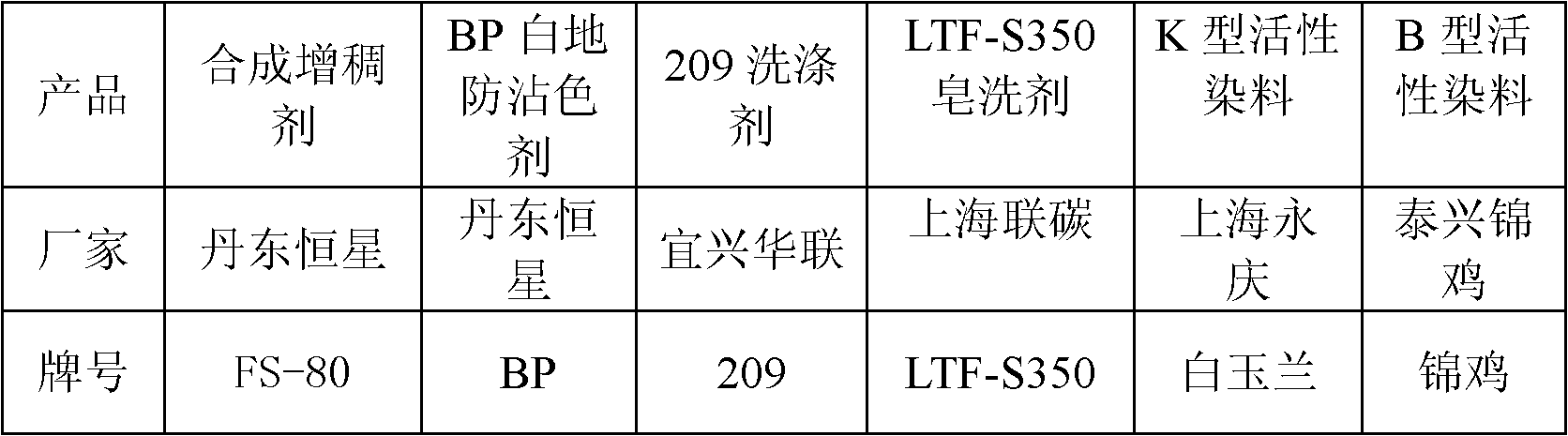

[0019] (1) Preparation and pre-processing: Do a good job in drafting and plate making, proofing and pulp preparation. Two printing pastes were prepared, both of which contained dyes, pastes and color fixing agents, wherein the pastes were mixed with synthetic thickener and sodium alginate in a weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com