Dyeing process of regenerated polyester

A recycled polyester and process technology, applied in the field of textile printing and dyeing, can solve the problems of low strength, unstable dyeing shade, and poor color fastness of recycled polyester fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The present embodiment provides a dyeing process of light beige (light-colored) regenerated polyester, characterized in that the dyeing process comprises the following steps:

[0076] (1) High-temperature pre-setting: Pre-setting the recycled polyester fabric at 185°C for 35 seconds;

[0077] (2) Pre-treatment degreasing: Use 2g / L degreaser LYS to degrease the pre-set recycled polyester fabric in step (1) at 70°C for 15 minutes;

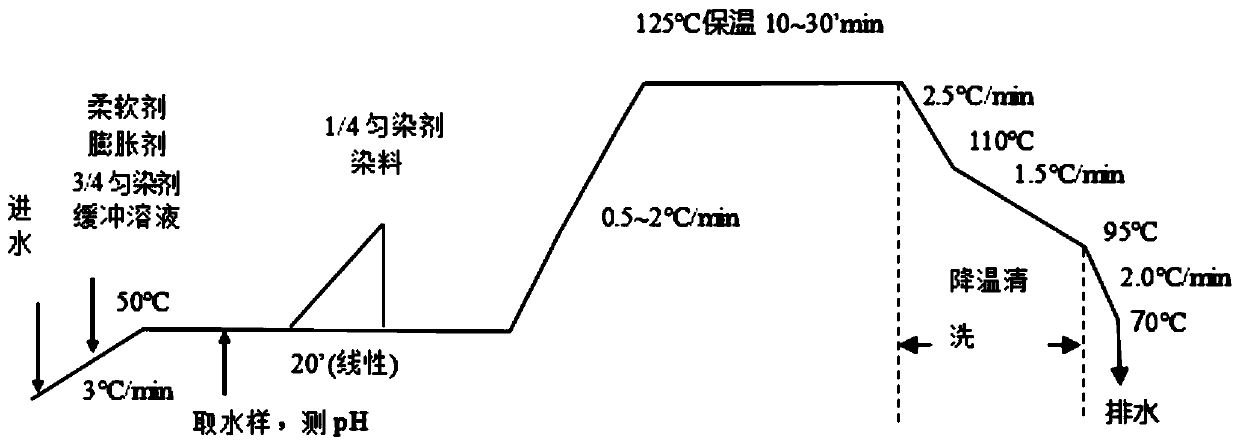

[0078] (3) Dyeing: Put the regenerated polyester fabric after the pre-treatment and degreasing in step (2) in the dyeing vat, add water to soak it according to the bath ratio of 1:10, add softener CN, swelling agent D, 3 / 4 leveling agent P and buffer solution (glacial acetic acid and sodium acetate), then heat up to 50°C at a rate of 3°C / min, then add the remaining 1 / 4 leveling agent P and dyes to the dye vat and mix evenly, then Carry out segmental heating dyeing, the specific heating process of the dyeing is: add the dye solution at a temp...

Embodiment 2

[0085] The difference from Example 1 is only that the mass concentration of the leveling agent in the dye liquor is 0.5g / L, and the others are the same as in Example 1.

Embodiment 3

[0087] The difference from Example 1 is that the mass concentration of the leveling agent in the dye liquor is 1.0 g / L, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com