Hydrogen peroxide localized catalytic compound additive and its application in cotton pretreatment

A technology of hydrogen peroxide and composite additives, which is applied in the fields of biochemical fiber treatment, fiber treatment, textiles and papermaking, etc., can solve the problems of high cost, complicated synthesis process, limited application, etc., and achieve low processing cost, simplified system, and auxiliary The effect of drug cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

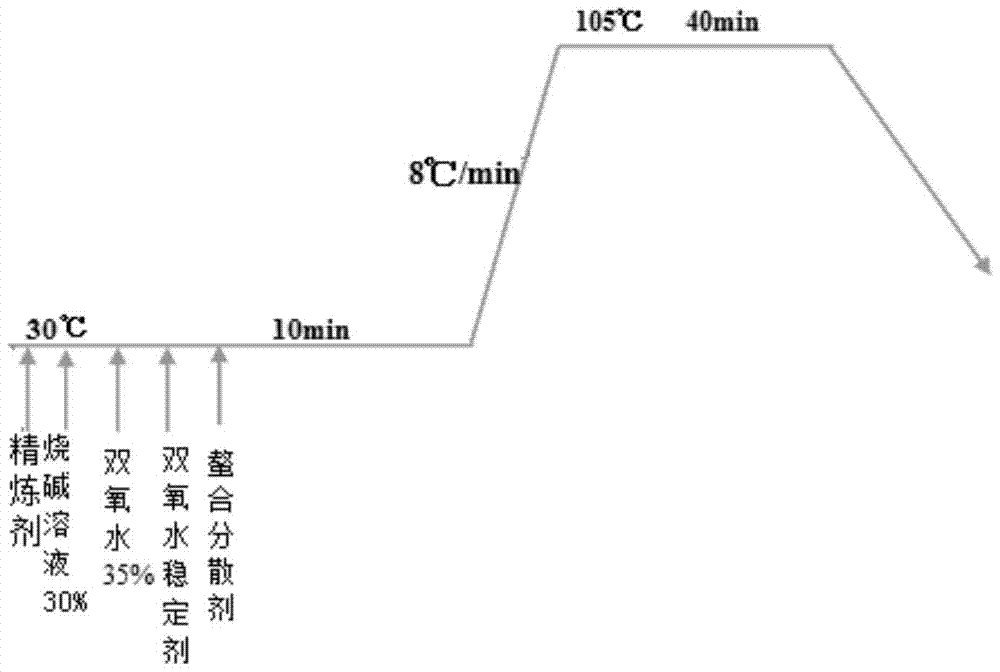

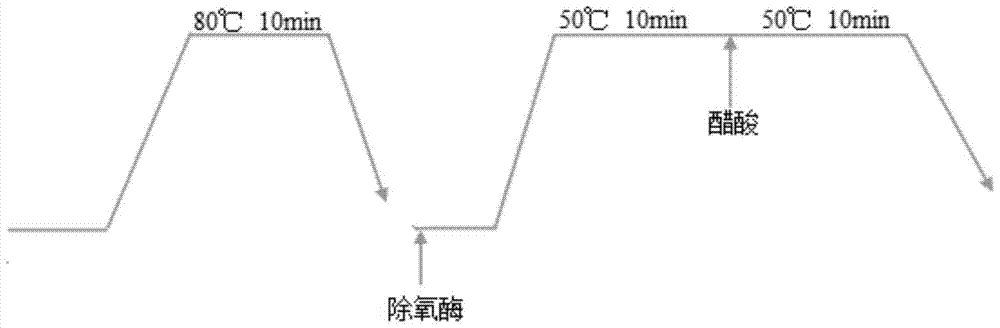

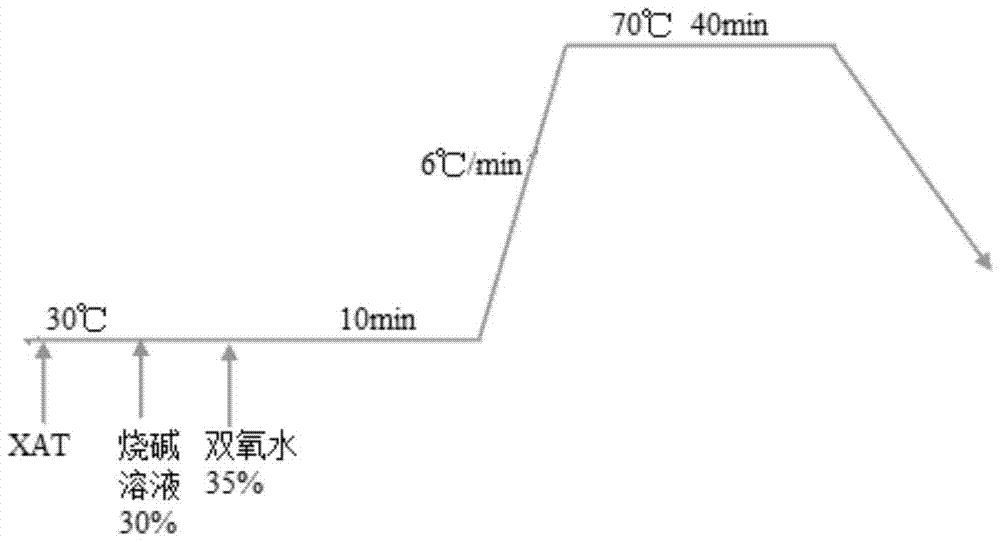

Method used

Image

Examples

Embodiment 1

[0097] Hydrogen peroxide localized catalytic compound additive XAT is composed of the following raw materials according to mass percentage:

[0098] Copper sulfate 3%, iron sulfate 0.002%, ammonia water 3%, lactic acid 3%, dodecyl dimethyl benzyl ammonium chloride 3%, flat plus O 3%, sodium dodecylsulfonate 3%, lauryl Sodium alkyl sulfate 3%, 78.998% of purified water, the sum of the contents of the above components is 100%;

[0099] The preparation method of hydrogen peroxide positioning catalytic composite auxiliary agent XAT, respectively weigh the following raw materials according to mass percentage: copper sulfate 3%, iron sulfate 0.002%, ammonia water 3%, lactic acid 3%, dodecyl dimethyl benzyl chloride Ammonium chloride 3%, Pingping O 3%, sodium dodecylsulfonate 3%, sodium dodecylsulfate 3%, 78.998% of purified water, the total content of the above components is 100%; the weighed Pure water was heated to 40°C; the weighed copper sulfate, iron sulfate, ammonia water, la...

Embodiment 2

[0104] Hydrogen peroxide localized catalytic compound additive XAT is composed of the following raw materials according to mass percentage:

[0105] 2.5% copper sulfate, 0.001% iron sulfate, 2.5% ammonia water, 2.5% citric acid, 2.5% dodecyl dimethyl benzyl ammonium chloride, 2.5% Pingpinga O, 2.5% sodium dodecyl sulfate , sodium lauryl sulfate 2.5%, 82.499% of purified water, the sum of the contents of the above components is 100%;

[0106] The preparation method of hydrogen peroxide positioning catalytic composite auxiliary agent XAT, respectively weighs the following raw materials according to mass percentage:

[0107] 2.5% copper sulfate, 0.001% iron sulfate, 2.5% ammonia water, 2.5% citric acid, 2.5% dodecyl dimethyl benzyl ammonium chloride, 2.5% Pingpinga O, 2.5% sodium dodecyl sulfate , sodium lauryl sulfate 2.5%, 82.499% of purified water, the sum of the contents of the above components is 100%; the copper sulfate, iron sulfate, ammonia water, citric acid, dodecyldim...

Embodiment 3

[0111] Hydrogen peroxide localized catalytic compound additive XAT is composed of the following raw materials according to mass percentage:

[0112] Cupric Chloride 5%, Ferric Chloride 0.003%, Ammonia 3.5%, Sulfosalicylic Acid 3.5%, Dodecyl Dimethyl Benzyl Ammonium Chloride 3.5%, Pingpinga O 3.5%, Lauryl 3.5% sodium sulfonate, 3.5% sodium lauryl sulfate, 73.997% of purified water, the total content of the above components is 100%;

[0113] The preparation method of hydrogen peroxide positioning catalytic composite auxiliary agent XAT, respectively weighs the following raw materials according to mass percentage:

[0114] Cupric Chloride 5%, Ferric Chloride 0.003%, Ammonia 3.5%, Sulfosalicylic Acid 3.5%, Dodecyl Dimethyl Benzyl Ammonium Chloride 3.5%, Pingpinga O 3.5%, Lauryl 3.5% sodium sulfonate, 3.5% sodium lauryl sulfate, 73.997% of purified water, the sum of the contents of the above components is 100%; the copper chloride, ferric chloride, ammonia water, sulfosalicyl Aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com