Environment-friendly dyeing process of regenerated nylon yarns

A kind of yarn, environmental protection technology, applied in the field of yarn, can solve the problem of no recycled nylon yarn dyeing process, and achieve the effect of saving dyeing water and energy resources, reducing harm, and good skin-friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

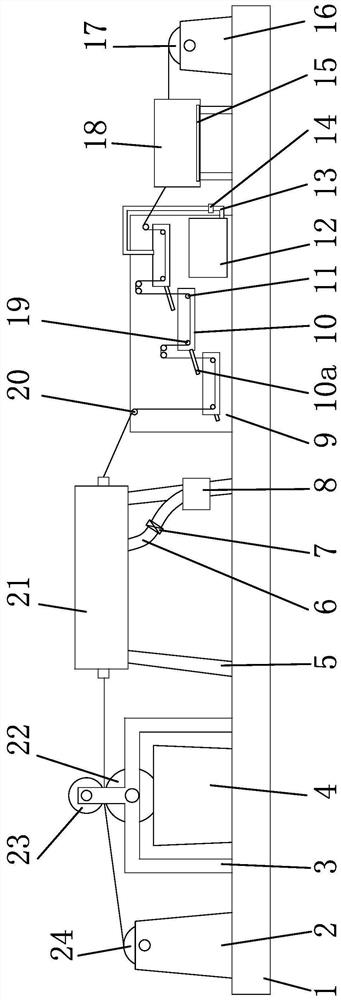

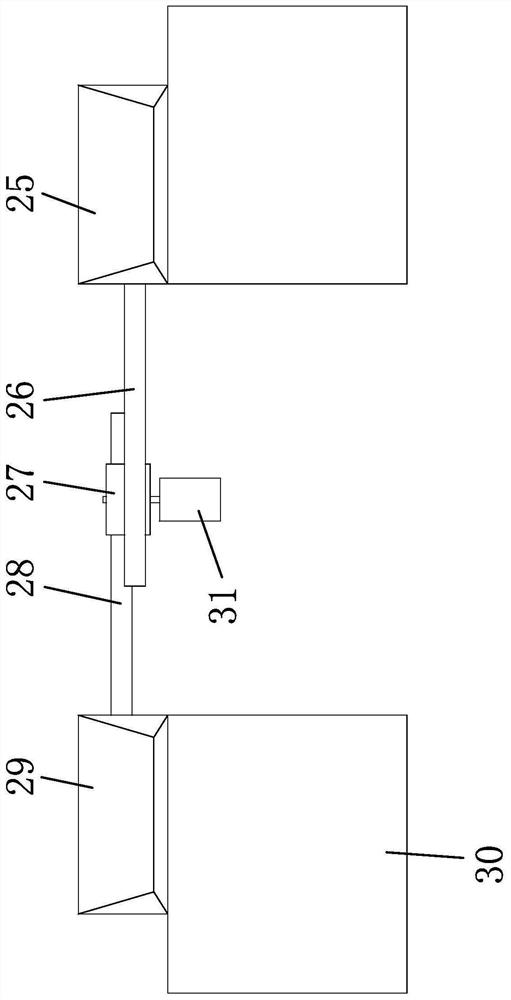

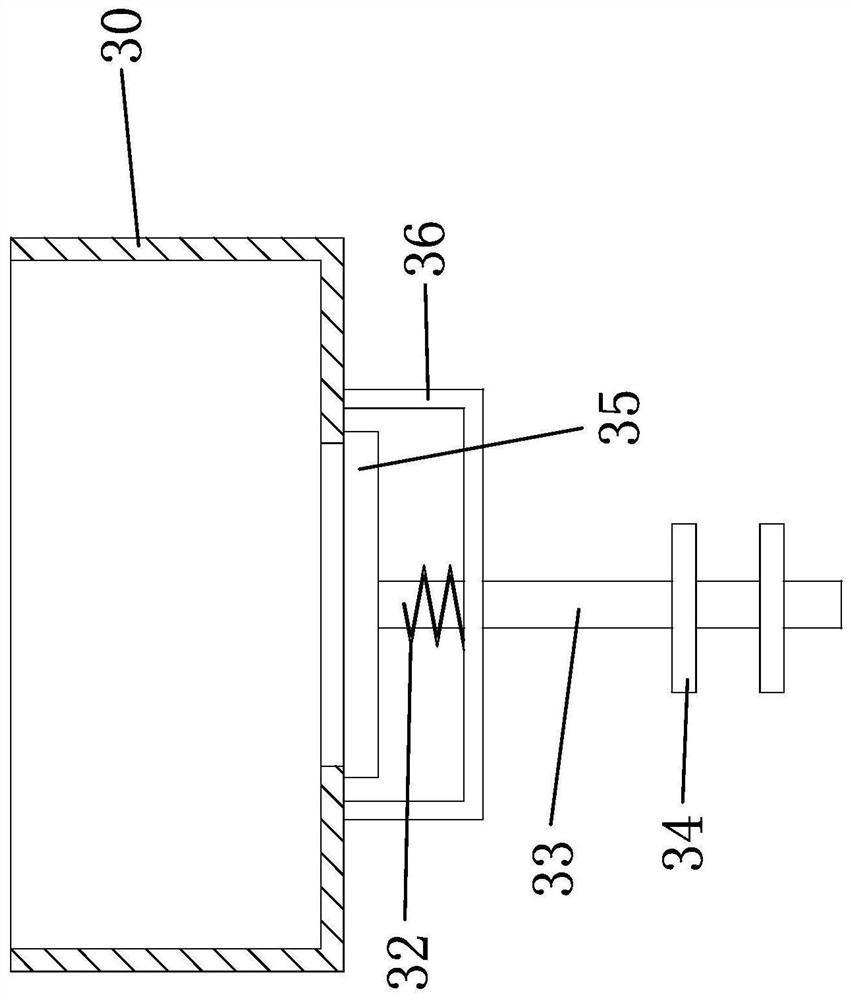

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0032] Such as Figure 1-Figure 4 As shown, the environmentally friendly dyeing process of the regenerated nylon yarn includes the following steps: the package yarn is processed by a padding yarn processing machine, which specifically includes: upper shaft, padding working fluid, oxidation curing, water washing, and drying , the lower axis.

[0033] The liquid rate of padding is 70%.

[0034] The working solution includes the following components: 5-6 g / L of bio-based dye, 10-30 g / L of soda ash, and 10-20 g / L of fermented sugar. In this embodiment, the fermented sugar is an existing product available on the market.

[0035] The padding type yarn processing machine includes a base plate 1, a discharge rack 2 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com