Viscose color-gorgeous blended blocky gray plus material and preparation method

A technology for ash and fabrics, applied in the field of textile manufacturing, can solve the problems of the performance of viscose filaments, poor color control of finished products, difficulty in color paste deployment, etc. Spinning convenience effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

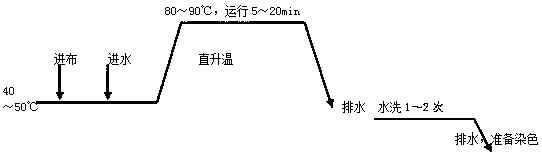

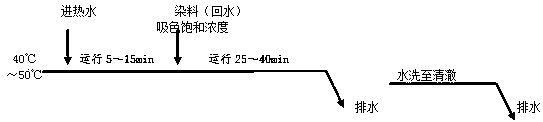

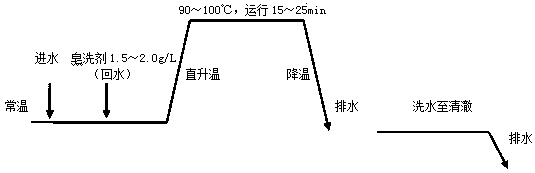

Examples

Embodiment 1

[0053] A kind of gray fabric of viscose Licai blending, the content is 65wt% viscose fiber and content is 35wt% Viscose fiber and the mode that is mixed with 35wt% Licai fiber is blended into blended yarn, then the blended yarn is carried out plain weave weaving, at the same time It is prepared by adding 20D spandex filaments in each way by plating.

[0054] The blended yarn adopts a compact Siro spinning method, and the yarn spun by this spinning method has uniform dryness, less hairiness, high strength, and the woven fabric has clear lines and is resistant to pilling.

[0055] The count of the mixed yarn is 40S / 1, and the twist is the twist of the knitting yarn.

[0056] A method for preparing a viscose and colorful blended gray fabric, comprising the steps of:

[0057] (1) Spinning

[0058] Using viscose fiber and Licai fiber as raw materials, the cotton bales are mixed through the plucking machine, and the spinning method of compact siro spinning yarn is used to obtain m...

Embodiment 2

[0079] A kind of gray fabric of viscose Licai blending, which is blended into a blended yarn by mixing viscose fiber with a content of 90 wt% and Licai fiber with a content of 10 wt% through cotton bales, and then the blended yarn is weaved in plain weave, At the same time, the method of plating is adopted, and 40D spandex filament is added to each road to prepare it.

[0080] The blended yarn adopts a compact Siro spinning method, and the yarn spun by this spinning method has uniform dryness, less hairiness, high strength, and the woven fabric has clear lines and is resistant to pilling.

[0081] The count of the mixed yarn is 80S / 1, and the twist is the twist of the knitting yarn.

[0082] A method for preparing a viscose and colorful blended gray fabric, comprising the steps of:

[0083] (1) Spinning

[0084] Using viscose fiber and Licai fiber as raw materials, the cotton bales are mixed through the plucking machine, and the spinning method of compact siro spinning yarn ...

Embodiment 3

[0105] A kind of gray fabric of viscose Licai blend, which is blended into blended yarn by mixing viscose fiber with 80 wt% viscose fiber and Licai fiber with 20 wt% Licai fiber content through cotton bales, and then plain weave weaving of the blended yarn, At the same time, the method of plating is adopted, and 30D spandex filament is added to each road to prepare it.

[0106] The blended yarn adopts a compact Siro spinning method, and the yarn spun by this spinning method has uniform dryness, less hairiness, high strength, and the woven fabric has clear lines and is resistant to pilling.

[0107] The count of the mixed yarn is 60S / 1, and the twist is the twist of the knitting yarn.

[0108] A method for preparing a viscose and colorful blended gray fabric, comprising the steps of:

[0109] (1) Spinning

[0110] Using viscose fiber and Licai fiber as raw materials, the cotton bales are mixed through the plucking machine, and the spinning method of compact siro spinning yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com