Method for producing galvanized steel plate

A galvanized steel sheet and a manufacturing method, which are applied in the directions of fusion spraying, hot-dip plating, superimposed layer plating, etc., can solve problems such as low surface activity, and achieve reduced friction coefficient, good stretchability, Low sliding resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

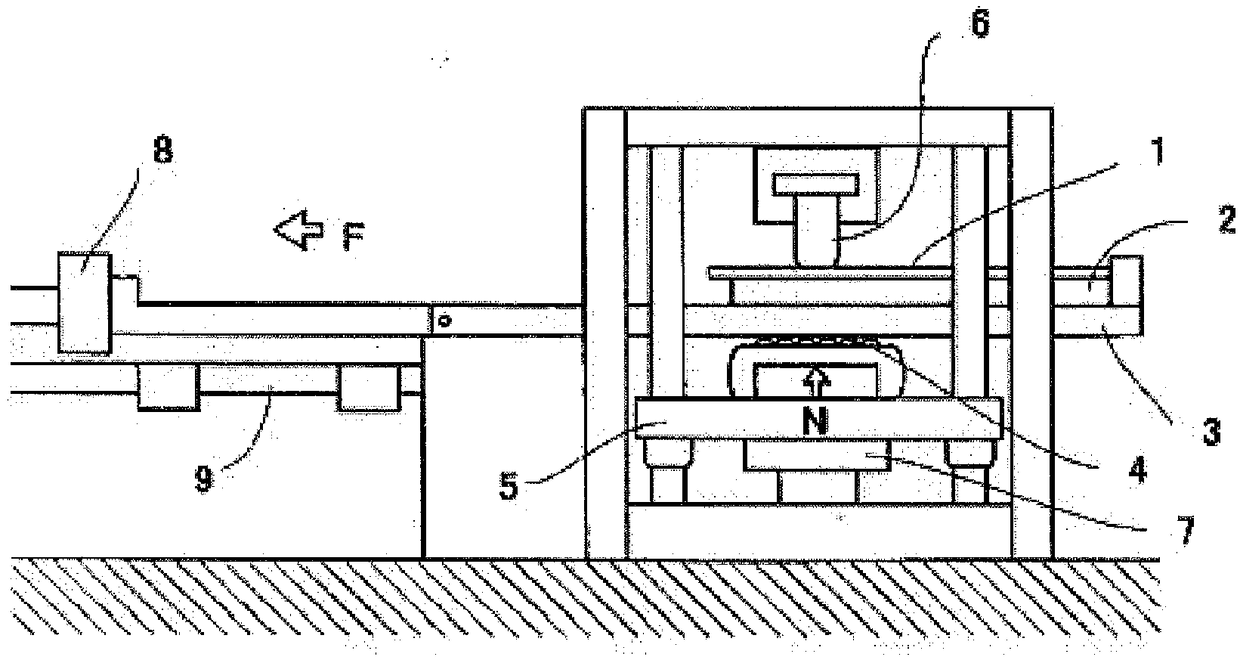

Method used

Image

Examples

Embodiment

[0066] The present invention is further described in detail through examples.

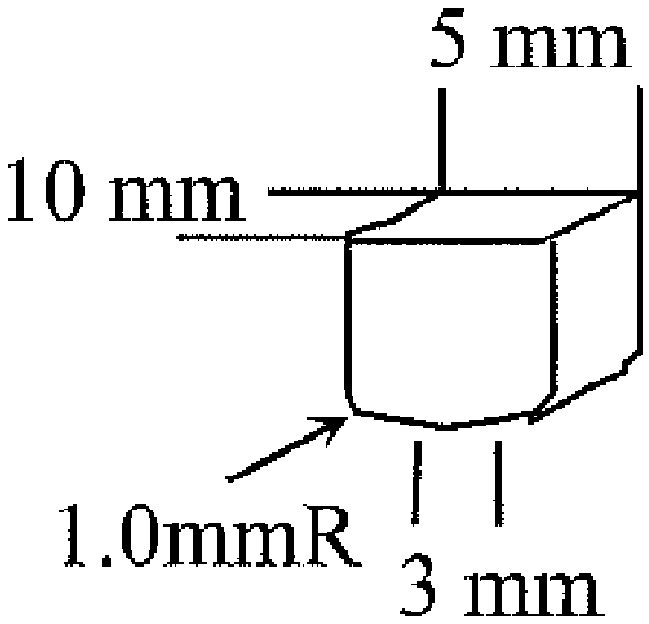

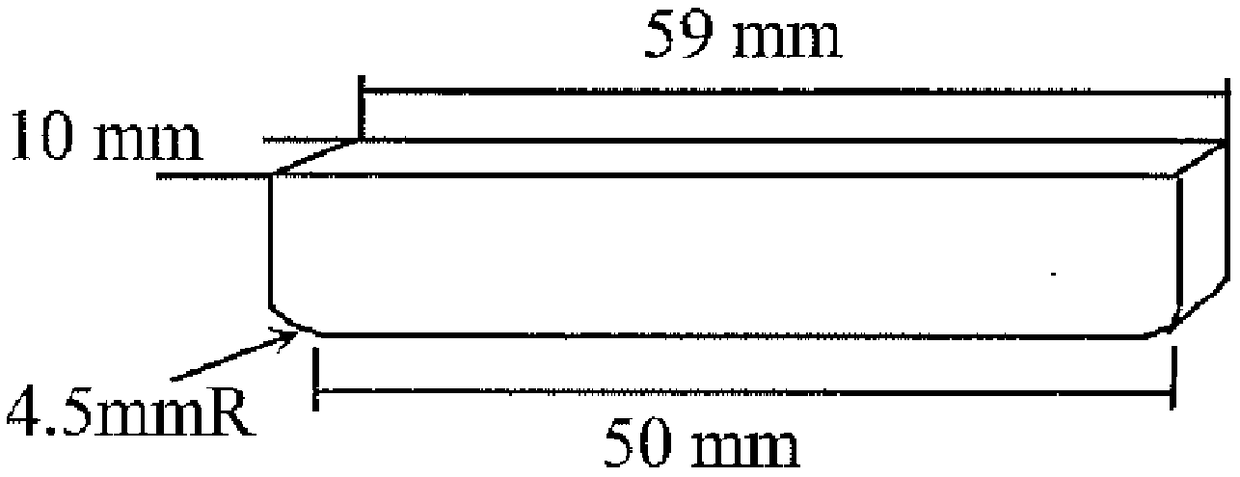

[0067] Hot-dip galvanizing was performed by a conventional method on a steel sheet having a thickness of 0.7 mm and annealed after cold-rolling, and an alloying treatment was performed on a part after hot-dip galvanizing. Next, temper rolling is performed. Adjust the amount of galvanizing to 45g / m on each side 2 , the Fe content of the plated film after the alloying treatment was adjusted to 10% by mass. After temper rolling, dip in an acidic solution containing 30 g / L sodium acetate and a pH of 1.5 in an acidic solution tank and lift it up. Adjust the amount of liquid film. HF in acidic solution 2 Na, HF 2 The concentration of K was set at 0 to 10.00 g / L, and the liquid temperature was set at 35°C. The amount of liquid film is adjusted by changing the pressure of the squeeze roller. After adjusting the amount of the liquid film, leave it (hold) for 1 to 30 seconds, then spray warm water at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com