Method of manufacturing heat-resistant component

A component and heat-resistant technology, applied in transportation and packaging, metal processing equipment, etc., can solve problems such as difficult three-dimensional control linear shrinkage, large linear shrinkage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0111] According to the contents shown in Table 1 below, a mixture comprising metal powder, polyvinyl butyral and ethanol was prepared. A container with a volume of 1000 ml and a ball mill are used. According to the conditions shown in Table 1 below, a mixture was prepared by mixing metal powder, polyvinyl butyral, and ethanol at room temperature for 1 hour.

[0112] As the metal powder, HK-30 manufactured by Parmaco (Visingen, Switzerland) with an average particle diameter of 5 μm to 9 μm was used. HK-30 contains 0.20 to 0.50% by weight of carbon (C), 24 to 27% by weight of chromium (Cr), 19 to 22% by weight of nickel (Ni), 0.75 to 1.30% by weight of silicon (Si), more than 0 And less than or equal to 1.5% by weight of manganese (Mn), 0.2 to 0.3% by weight of molybdenum (Mo), 1 to 1.75% by weight of niobium (Nb), and the rest of iron (Fe) and unavoidable impurities.

[0113] 【Table 1】

[0114]

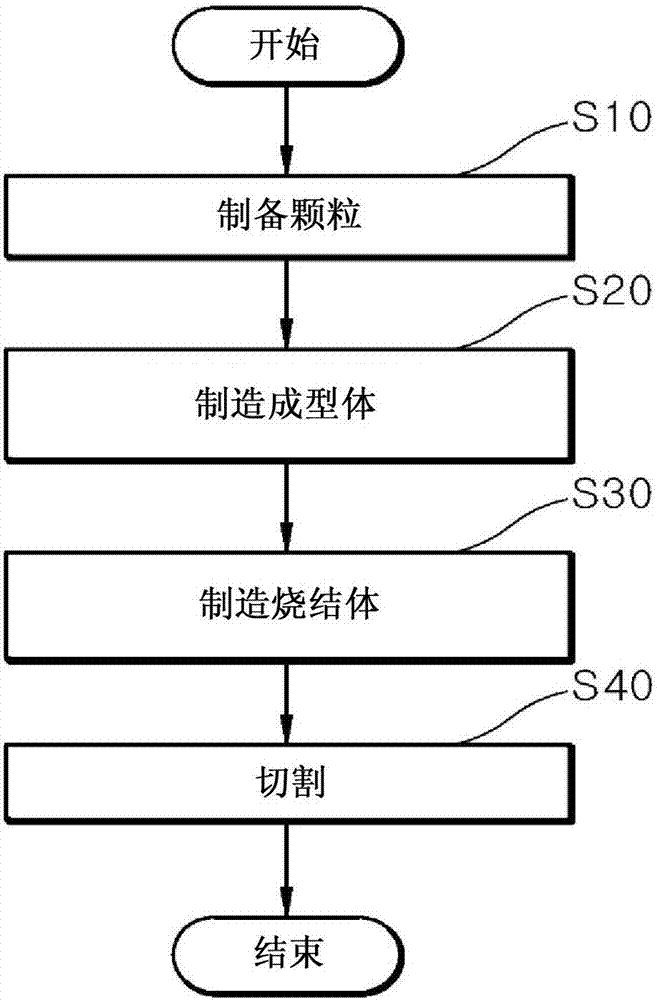

[0115] Such as Figure 6 As shown, pellets were prepared by injecting the ...

example 2

[0119] A heat-resistant component was manufactured by the same method as in Example 1, except that a mixture was prepared using the components and contents summarized in Table 2 below.

[0120] 【Table 2】

[0121]

example 3

[0123] Except at 600MPa (ie, 6.12 tons / cm 2 ) under the pressure of compression molding, by the same method as Example 1 to manufacture heat-resistant components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com