Resin composition and laminate

A technology of resin composition and laminates, applied in the direction of synthetic resin layered products, layered products, packaged article types, etc. Excellent lamination formability, good bondability, and the effect of good bondability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

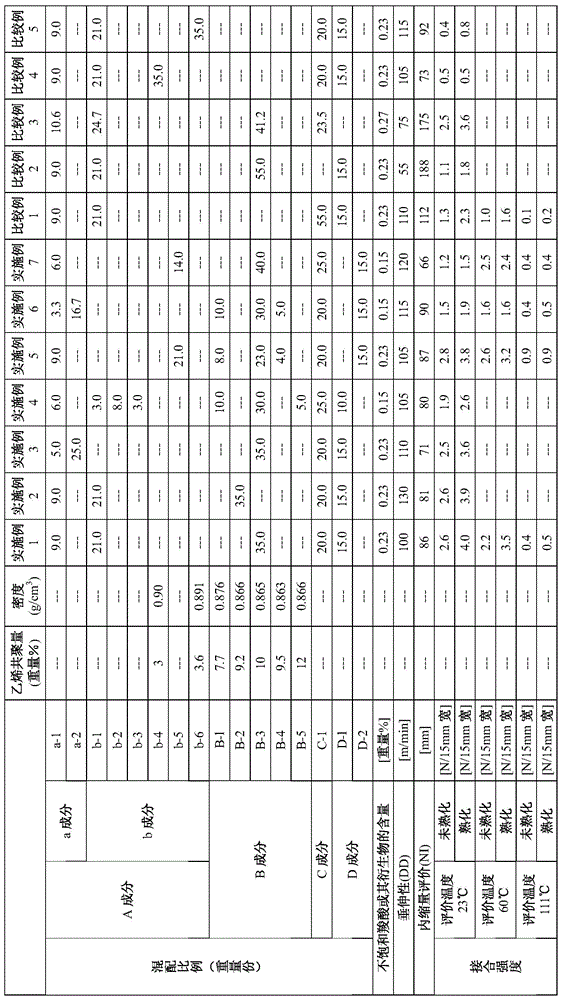

[0189] 9.0% by weight of a-1, 21.0% by weight of b-1, 35.0% by weight of B-3, 20.0% by weight of C-1, and 15.0% by weight of D-1 (total 100% by weight) were previously dry blended For mixing, use a twin-screw extruder PCM45 manufactured by Ikegai Manufacturing Co., Ltd. to melt and knead at a temperature of 200°C, a screw speed of 300 rpm, and an extrusion volume of 25 kg / hr, extrude into a ribbon shape, and cool After that, cutting was performed to obtain a pelletized resin composition.

Embodiment 2~7 and comparative example 1~5

[0191] Except that the raw materials and their mixing ratios were as shown in Table-1, melt-kneading was carried out in the same manner as in Example 1 to obtain a resin composition. However, in Example 3 and Example 6, in addition to the various materials in Table-1, with respect to the total amount of 100% by weight, 0.1% by weight of DHT4A (hydrotalcite manufactured by Kyowa Chemical Industry Co., Ltd.) was added. Compound).

[0192]

[0193] Random polypropylene was used as the outer layer, and the resin compositions obtained in Examples 1 to 7 and Comparative Examples 1 to 5 were used as the inner layer (bonding material layer), and an outer layer of 20 μm was obtained by the following molding method , A laminate for evaluating joint strength with an inner layer of 10 μm.

[0194]

[0195] ·Forming machine: Two kinds of two-layer co-extrusion laminating machine manufactured by Sumitomo Heavy Industries Modern

[0196] (The extruders are all single screw extruders)

[0197] ·Coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com