Zinc phosphate treated galvanized steel sheet and manufacturing method thereof

A technology of galvanized steel sheet and manufacturing method, applied in hot-dip plating process, superimposed layer plating, coating, etc., can solve problems such as uneven appearance, achieve no uneven appearance, excellent press formability, and stable manufacturing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

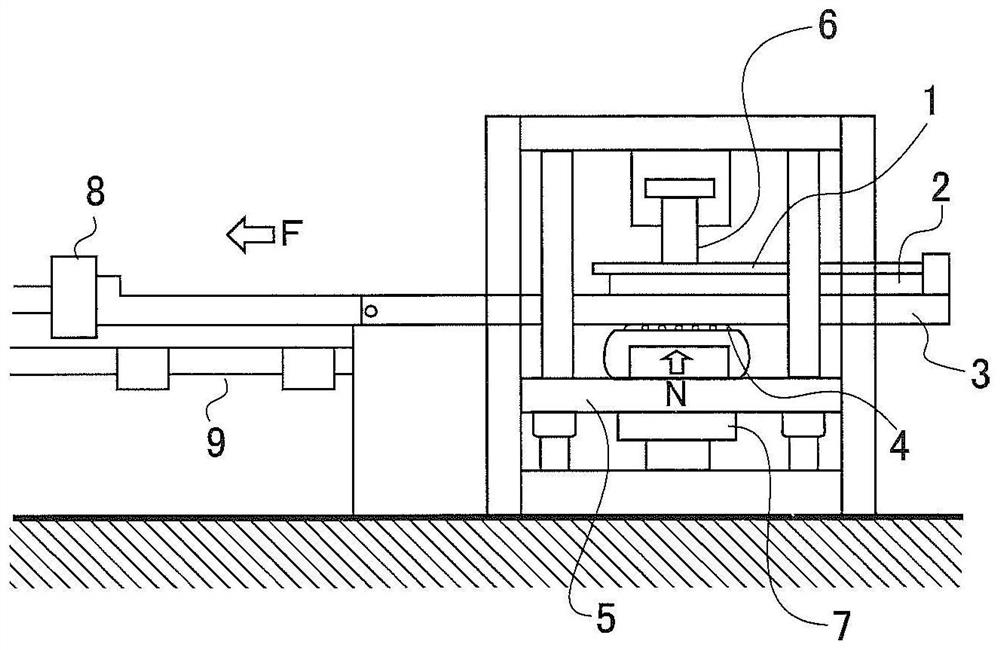

[0049] Steel sheets with a thickness of 0.7 mm that have been annealed after cold rolling are electrogalvanized by a common method, and then dipped in a surface conditioning treatment solution of 3.0 g / L at 40°C ("PL- ZN") for 3 seconds, thereby implementing a surface conditioning treatment. Next, the zinc phosphate treatment solution having the composition shown in Table 1 was blown onto the galvanized steel sheet from the slit nozzle at the predetermined blowing angle shown in Table 2, thereby forming a zinc phosphate-based film.

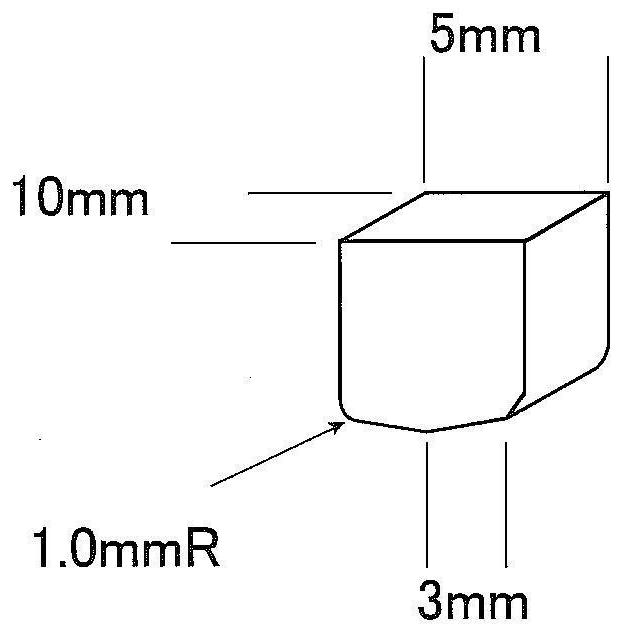

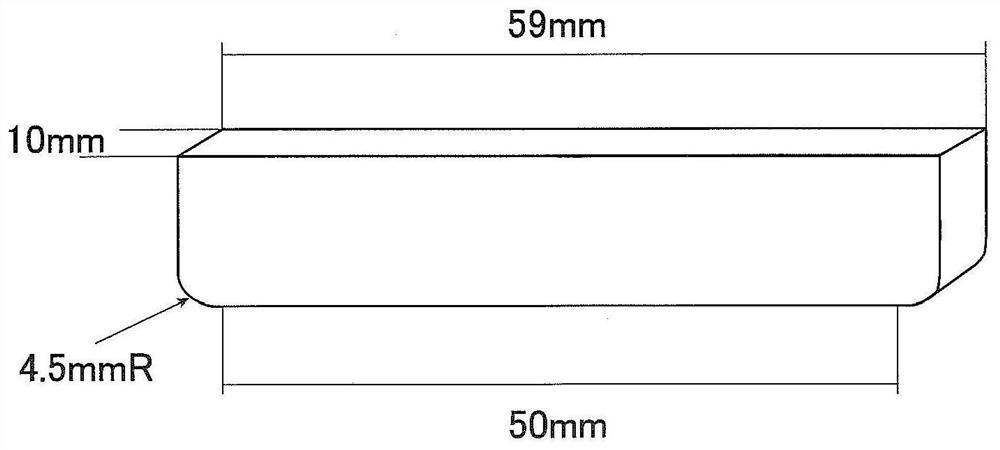

[0050] It should be noted that the slit nozzle is Figure 4 The configuration of the slit nozzle is set as the blowing conditions of zinc phosphate treatment liquid sprayed by the slit nozzle. , The injection pressure is set to 0.5kgf / cm 2 .

[0051] [Table 1]

[0052] PO 4 (g / L)

15.7 Zn(g / L) 1.4 Ni(g / L) 0.5~1.3 Mn(g / L) 0.5~3.5 NO 3 (g / L)

2.5

[0053] For the obtained zinc phosphate-treated galva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| Adhesion amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com