Elastomer short fiber toughened crystalline polymer product and preparation method thereof

A crystalline polymer, short fiber technology, applied in the direction of conjugated synthetic polymer rayon, additive processing, etc., can solve the problem of polylactic acid impact strength and tensile strength decrease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Take the elastomeric polyurethane resin and put it into a vacuum oven at 80° C. to dry for 4 hours to obtain the dried elastomeric polyurethane resin for future use.

[0037] (2) Take the crystalline polylactic acid resin and put it into a vacuum oven at 80° C. to dry for 8 hours to obtain a dried crystalline polylactic acid resin for future use.

[0038] (3) raw materials are weighed according to the following mass percentages: 10% of the dried elastomer polyurethane resin obtained in step (1), 90% of the dried crystalline polylactic acid resin obtained in step (2), the mass percentages of the two raw materials The sum is 100%.

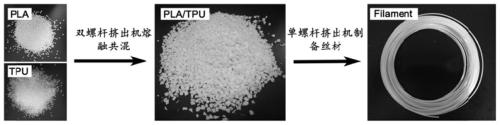

[0039] (4) Mix the raw materials weighed in step (3) and perform melt blending and granulation with twin-screws to obtain composite pellets with a diameter of 1.3 to 2.5 mm and a length of 5 to 7 mm, and vacuum-dry at 80°C for 12 hours Standby, during the extrusion process, the twin-screw speed is controlled at 160-180r / min, and the blend...

Embodiment 2

[0043] (1) Take the elastomeric polyurethane resin and put it into a vacuum oven at 80° C. to dry for 4 hours to obtain the dried elastomeric polyurethane resin for future use.

[0044] (2) Take the crystalline polylactic acid resin and put it into a vacuum oven at 80° C. to dry for 8 hours to obtain a dried crystalline polylactic acid resin for future use.

[0045] (3) raw materials are weighed according to the following mass percentages: 20% of the dried elastomer polyurethane resin obtained in step (1), 80% of the dried crystalline polylactic acid resin obtained in step (2), the mass percentages of the two raw materials The sum is 100%.

[0046] (4) Mix the raw materials weighed in step (3) and perform melt blending and granulation with twin-screws to obtain composite pellets with a diameter of 1.3 to 2.5 mm and a length of 5 to 7 mm, and vacuum-dry at 80°C for 12 hours Standby, during the extrusion process, the twin-screw speed is controlled at 160-180r / min, and the blend...

Embodiment 3

[0050] (1) Take the elastomeric polyurethane resin and put it into a vacuum oven at 80° C. to dry for 4 hours to obtain the dried elastomeric polyurethane resin for future use.

[0051] (2) Take the crystalline polylactic acid resin and put it into a vacuum oven at 80° C. to dry for 8 hours to obtain a dried crystalline polylactic acid resin for future use.

[0052] (3) raw materials are weighed according to the following mass percentages: 30% of the dried elastomer polyurethane resin obtained in step (1), 70% of the dried crystalline polylactic acid resin obtained in step (2), the mass percentages of the two raw materials The sum is 100%.

[0053] (4) Mix the raw materials weighed in step (3) and perform melt blending and granulation with twin-screws to obtain composite pellets with a diameter of 1.3 to 2.5 mm and a length of 5 to 7 mm, and vacuum-dry at 80°C for 12 hours Standby, during the extrusion process, the twin-screw speed is controlled at 160-180r / min, and the blend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com