Pole shoe used for slow-wave heat dissipation of millimeter traveling wave tube and production method thereof

A manufacturing method and technology for traveling wave tubes, which are applied in the manufacture of discharge tubes/lamps, cold cathodes, electrode systems, etc., can solve the problem that the thermal conductivity of the pole shoe cannot meet the slow wave heat dissipation of the traveling wave tube, and achieve the solution The problem of slow wave heat dissipation of traveling wave tube, the effect of improving service life and working accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

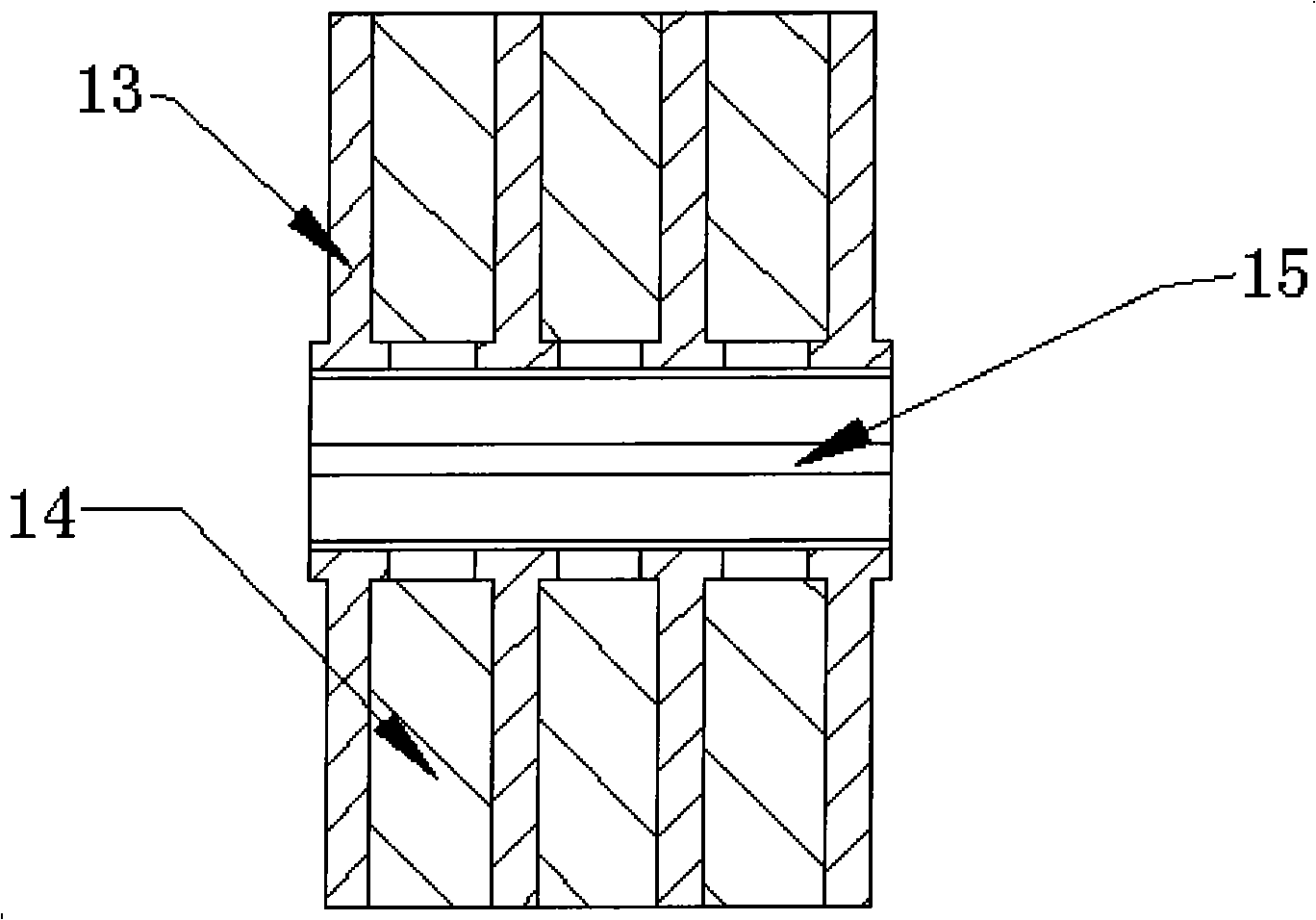

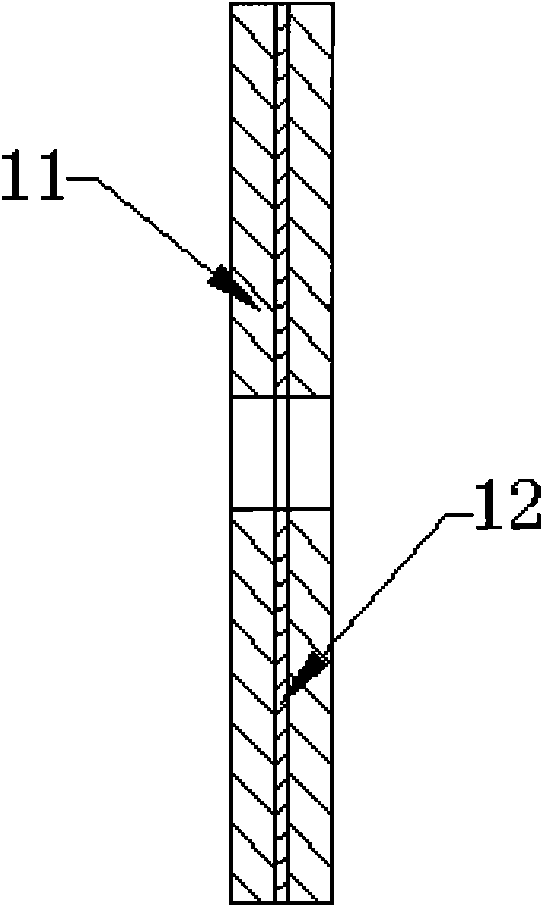

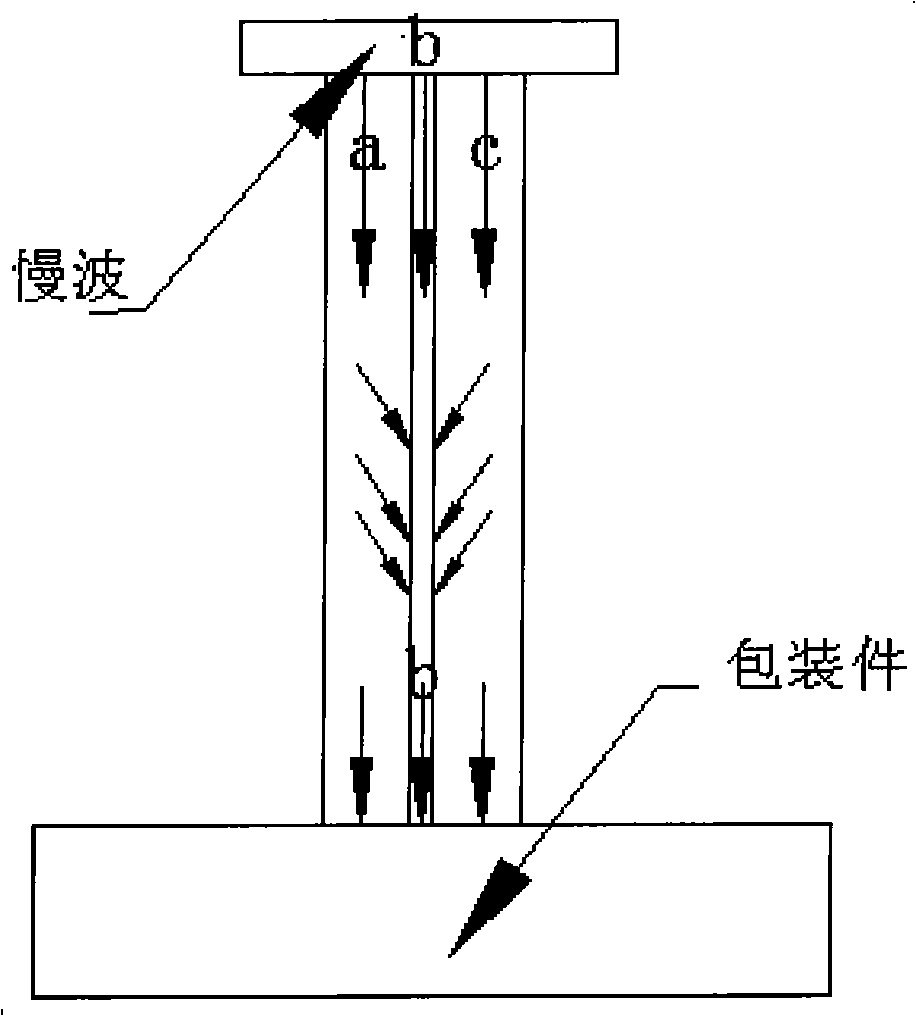

[0023] Such as figure 2 As shown, a pole shoe for slow wave heat dissipation of a millimeter traveling wave tube includes a pole shoe wall 11 made of DT8 magnetic material on both sides, and a heat conduction layer 12 of oxygen-free copper material is sandwiched between the pole shoe walls 11 , the mass of oxygen-free copper accounts for no more than 10% of the total mass of the pole piece, and the heat conduction layer 12 and the pole piece wall 11 are connected as a whole by diffusion welding.

[0024] Such as Figure 4 As shown, put the molybdenum base 1, spacer 9, and molybdenum rod 3 in order, and insert the centering rod 8 into the centering hole; insert the mica sheet 10, molybdenum spacer 5, pole shoe wall 11, and heat conduction layer 12 according to As shown in the figure, it is stacked in this way, wherein the mica sheet 10 is to prevent the parts from sticking together after diffusion welding and cannot be separated; press the inner pressure block 6, and set the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com