Method and device for manufacturing biaxial extending ribbon and device for bending ribbon

A manufacturing method and technology for strips, which are applied in the field of biaxially extending strips, can solve problems such as unpractical use and poor cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

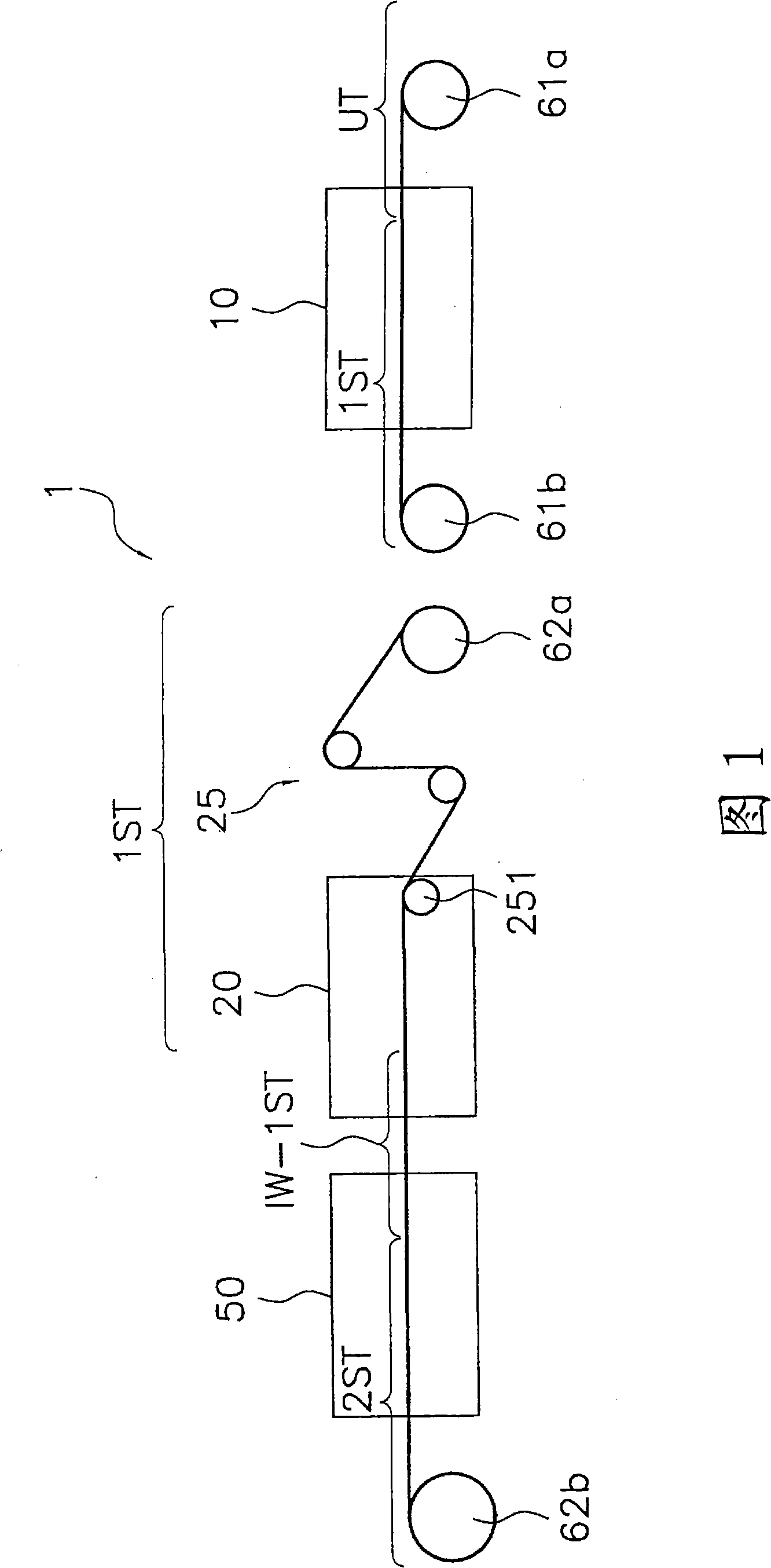

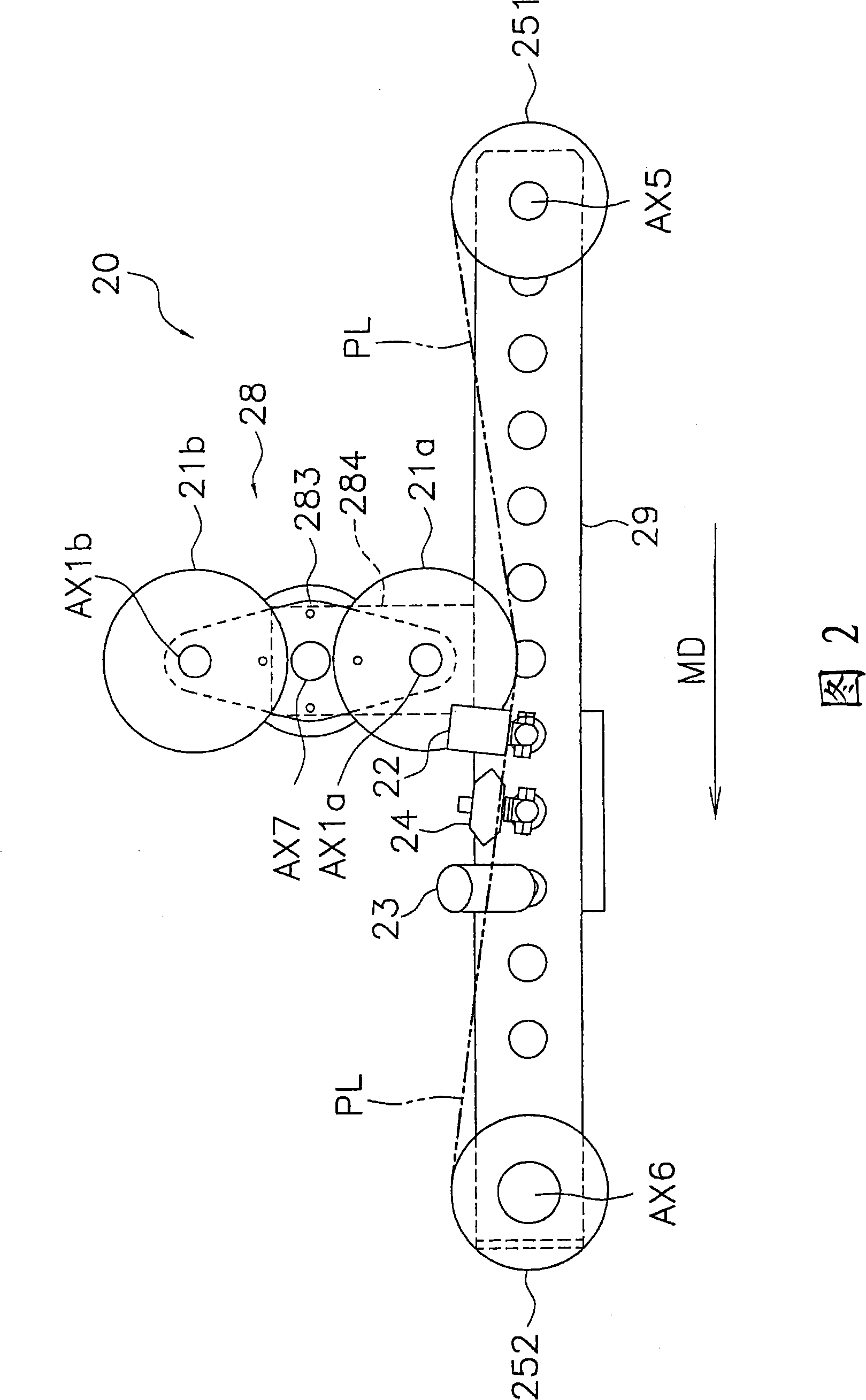

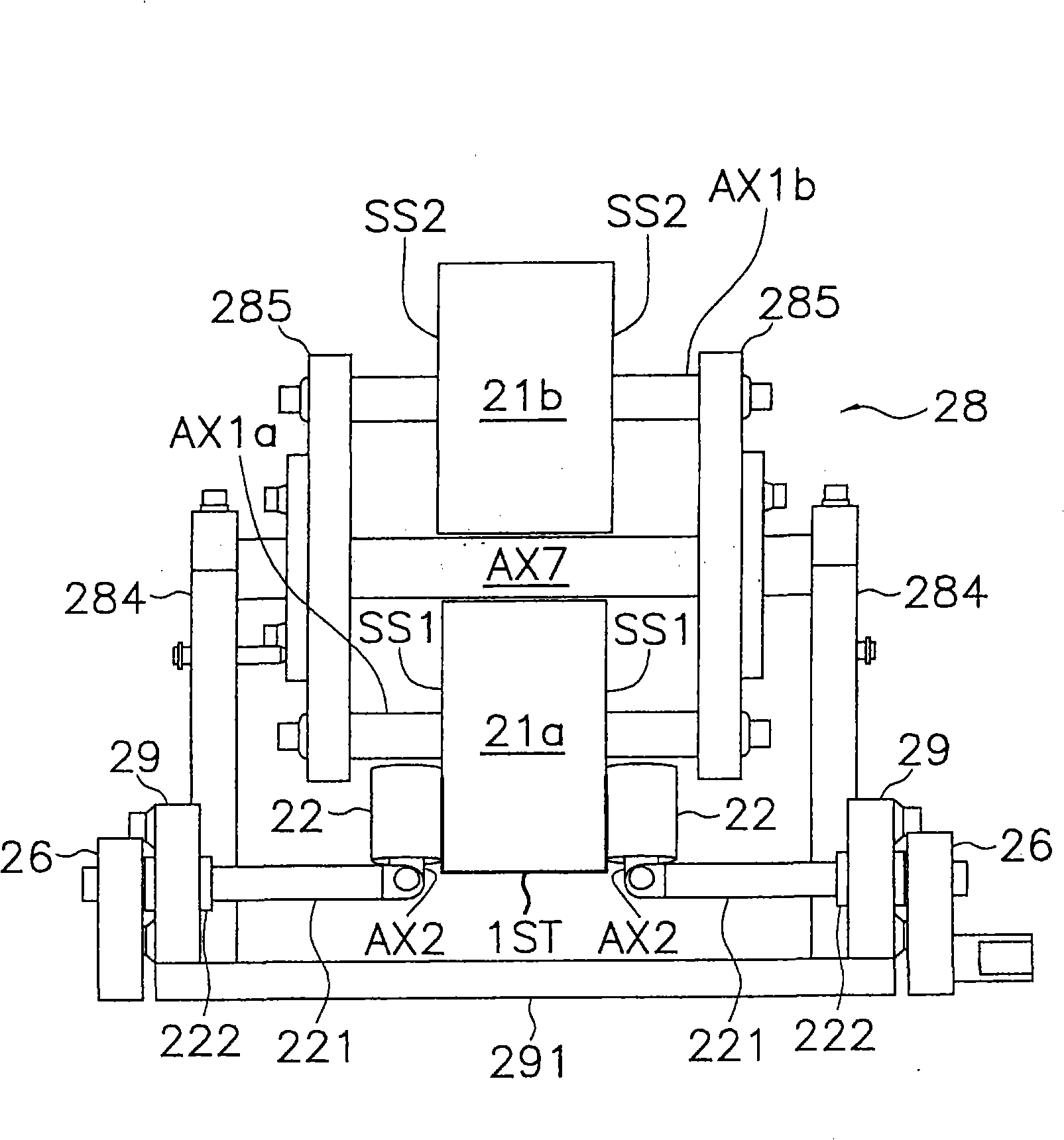

[0086] A biaxial stretching device 1 according to an embodiment of the present invention is a device for stretching an unstretched strip UT in the longitudinal direction and the width direction. As shown in FIG. The stretching device 10, the first winding roller 61b, the second conveying roller 62a, the tension adjusting roller type tension control mechanism 25, the turning back device 20, the tenter device 50, and the second winding roller 62b are constituted. In this biaxial stretching device 1, as shown in FIG. is extended in the longitudinal direction to form a uniaxially stretched belt 1ST, and the uniaxially stretched belt 1ST is wound by a first winding roll 61b. Furthermore, the first winding roller 61b around which the uniaxially stretched strip 1ST is wound is set as the second transport roller 62a, and the uniaxially stretched strip 1ST is transported from the second transport roller 62a, and in the turning-back device 20, Fold back both ends of the uniaxially stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com