Production method and system of maxillary defect prosthesis

A production method and jawbone technology, which are applied in dental prosthesis, medical science, image data processing, etc., can solve the problems of cumbersome production process, long cycle, long diagnosis and treatment cycle, etc., and achieve the effect of improving production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

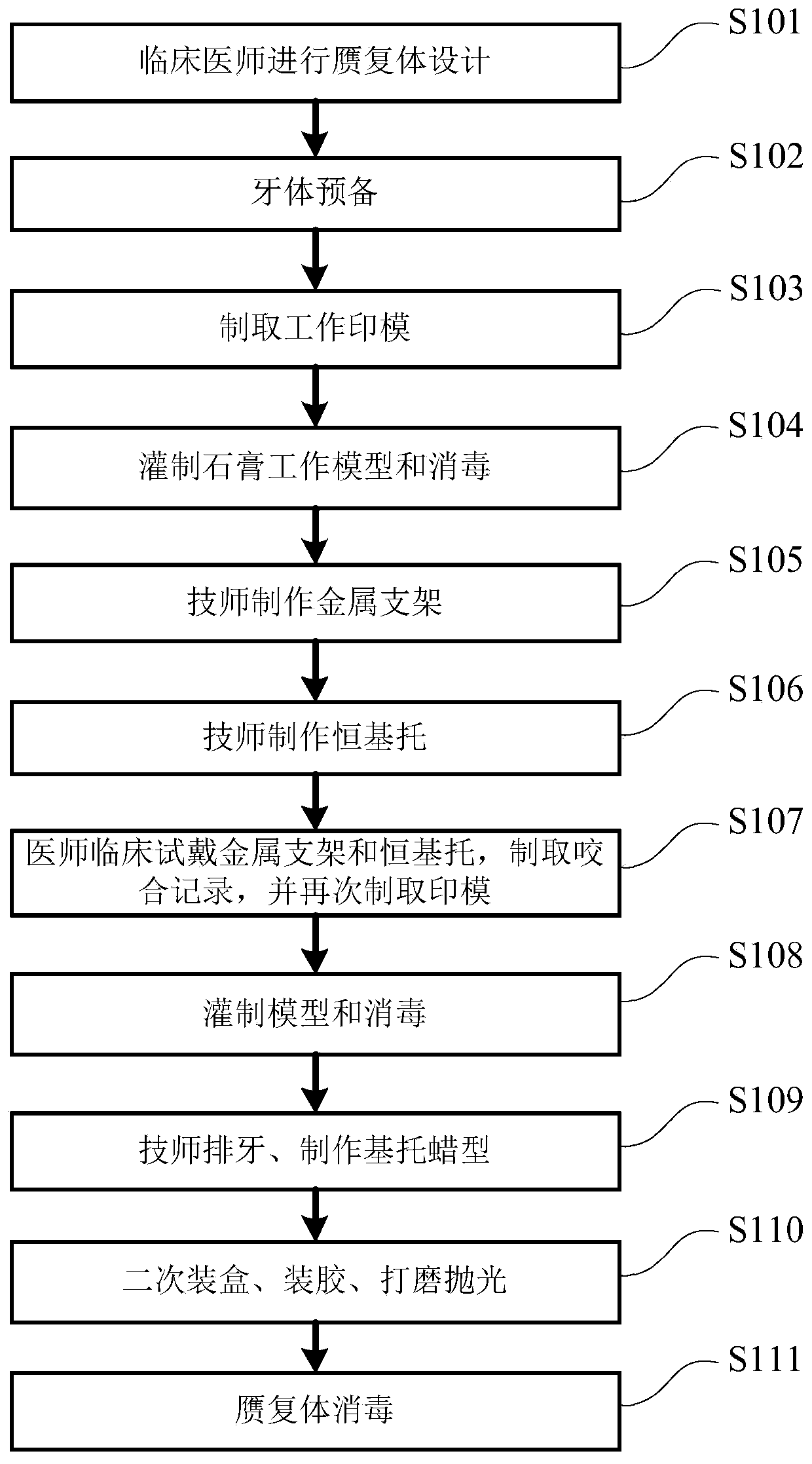

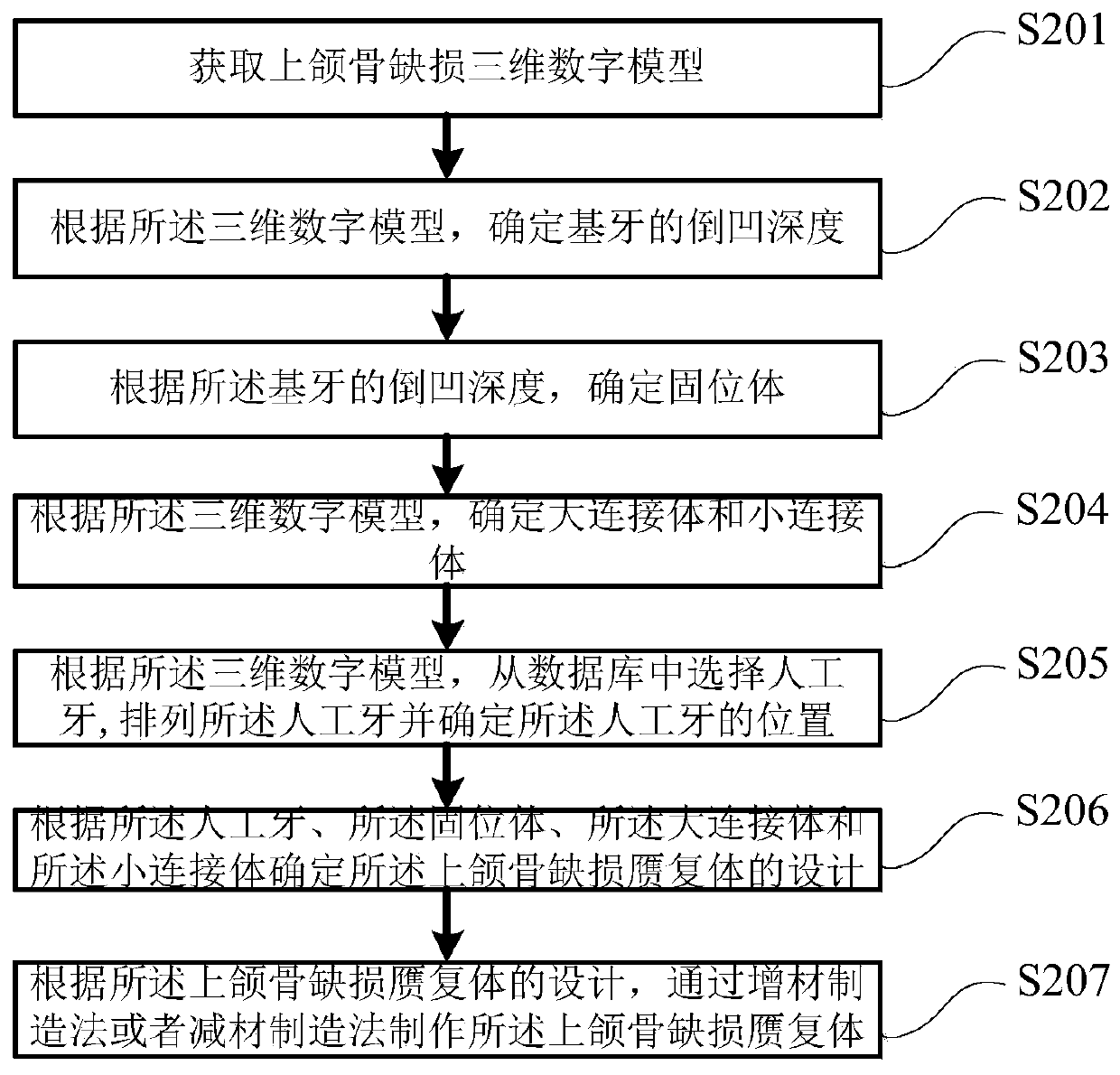

[0077] see figure 2 , is a schematic diagram of a fully digital design and fabrication method for a maxillary defect prosthesis provided in the embodiment of the present application. As shown in the figure, the process may include:

[0078] S201, acquiring a three-dimensional digital model of the maxillary defect;

[0079] Acquisition of the 3D digital model of the maxillary defect is the basis for digital fabrication. Preferably, the three-dimensional digital model of the maxillary defect can be obtained in the following ways:

[0080] The first way: direct access to technology. The three-dimensional digital model of the maxillary defect was obtained directly by combining spiral CT and intraoral scanning. For example, the 3D data of the maxillary defect cavity and dentition can be obtained through spiral CT scanning, the 3D data of the maxillary dentition and palate mucosa can be obtained through intraoral scanning, and the 3D digital model of the maxillary defect can be ...

Embodiment 2

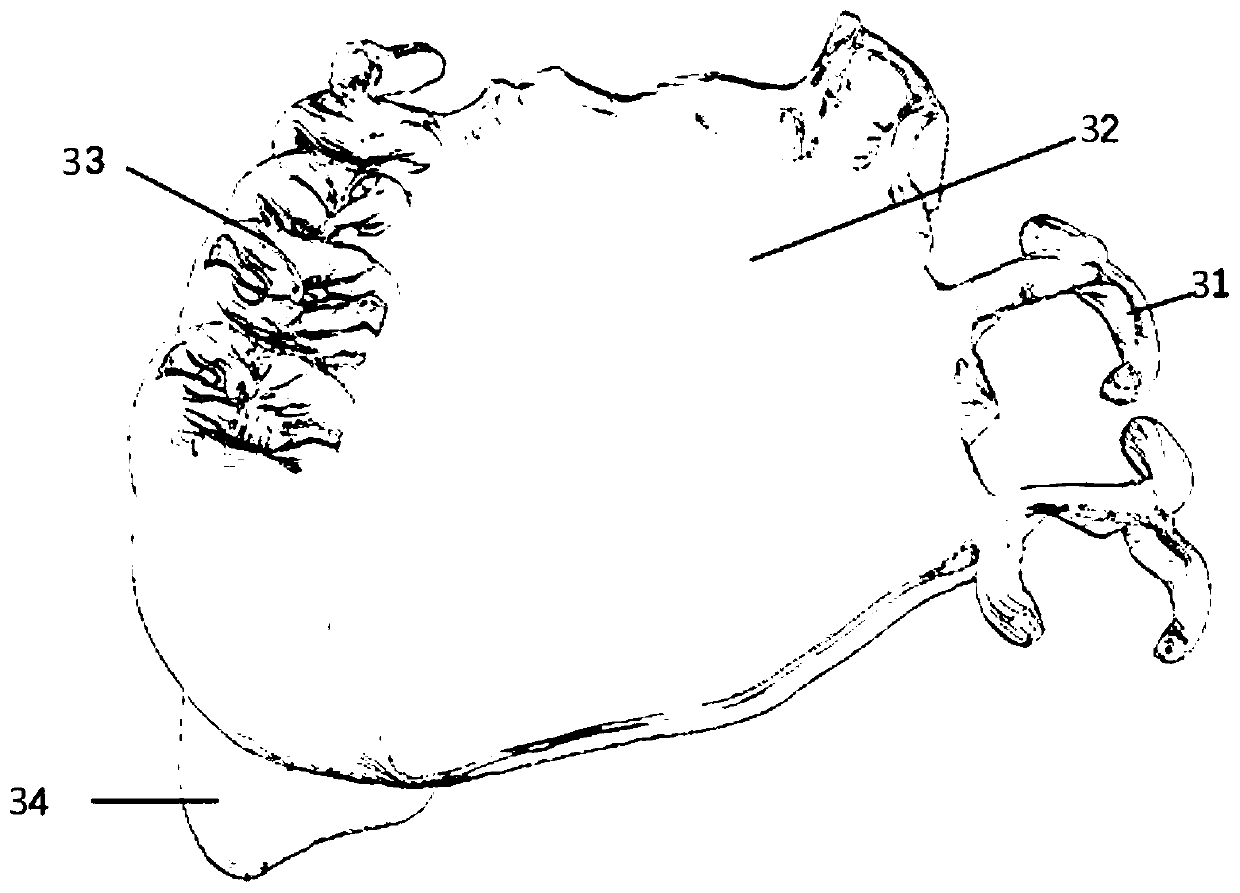

[0114] The embodiment of the present invention also provides a fully digital design and production system for maxillary defect prostheses, such as Image 6 shown, including:

[0115] A 3D digital model acquisition subsystem 601, configured to acquire a 3D digital model of the maxillary defect;

[0116] The computer-aided design CAD subsystem 602 is used to obtain the undercut depth according to the three-dimensional digital model, select artificial teeth from the database, and determine retainers, major connectors, minor connectors and bases to obtain the maxillary Design of bone defect prosthesis;

[0117] The prosthesis making subsystem 603 is configured to make the maxillary defect prosthesis according to the design of the maxillary defect prosthesis.

[0118] Further, the 3D digital model acquisition subsystem 601 is specifically used to acquire a 3D digital model of the maxillary defect in the following manner:

[0119] The three-dimensional data of the maxillary defec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com