Paper crusher combined structure blade and manufacture method thereof

A combined structure and paper shredder technology, applied in grain processing, etc., can solve problems such as separation and inability to withstand axial force, and achieve the effects of reducing production costs, reducing costs and weight, and reducing materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and examples.

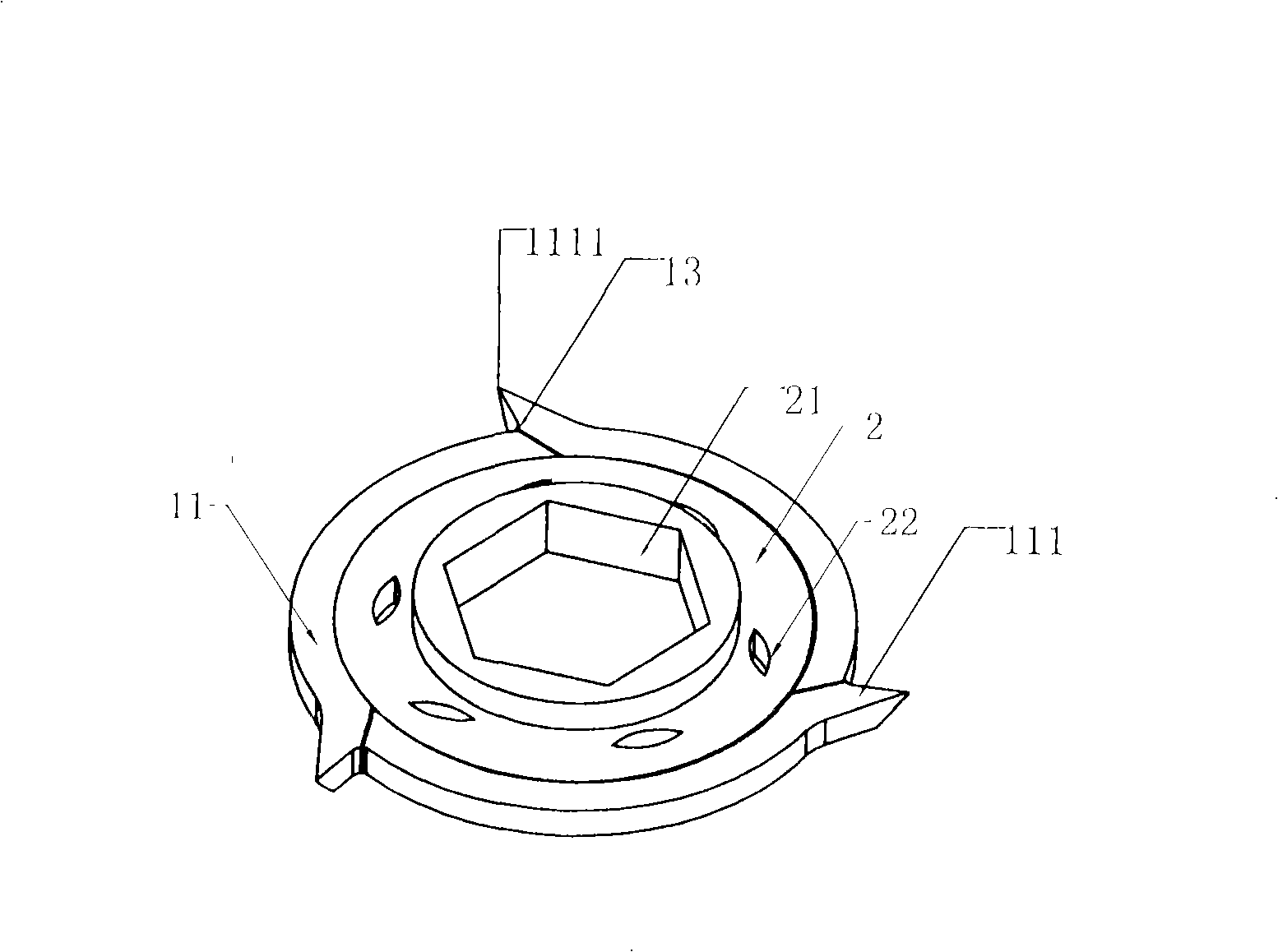

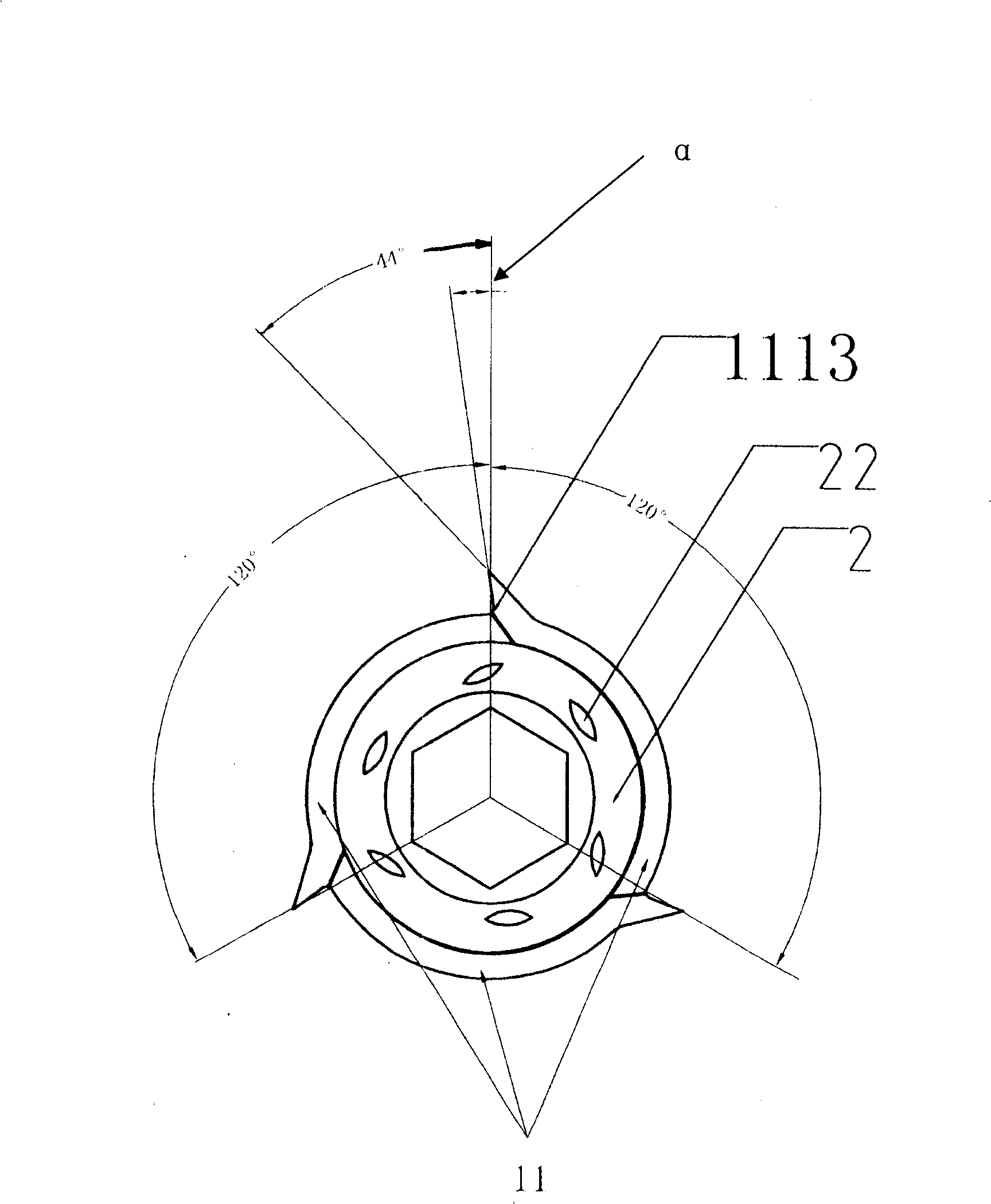

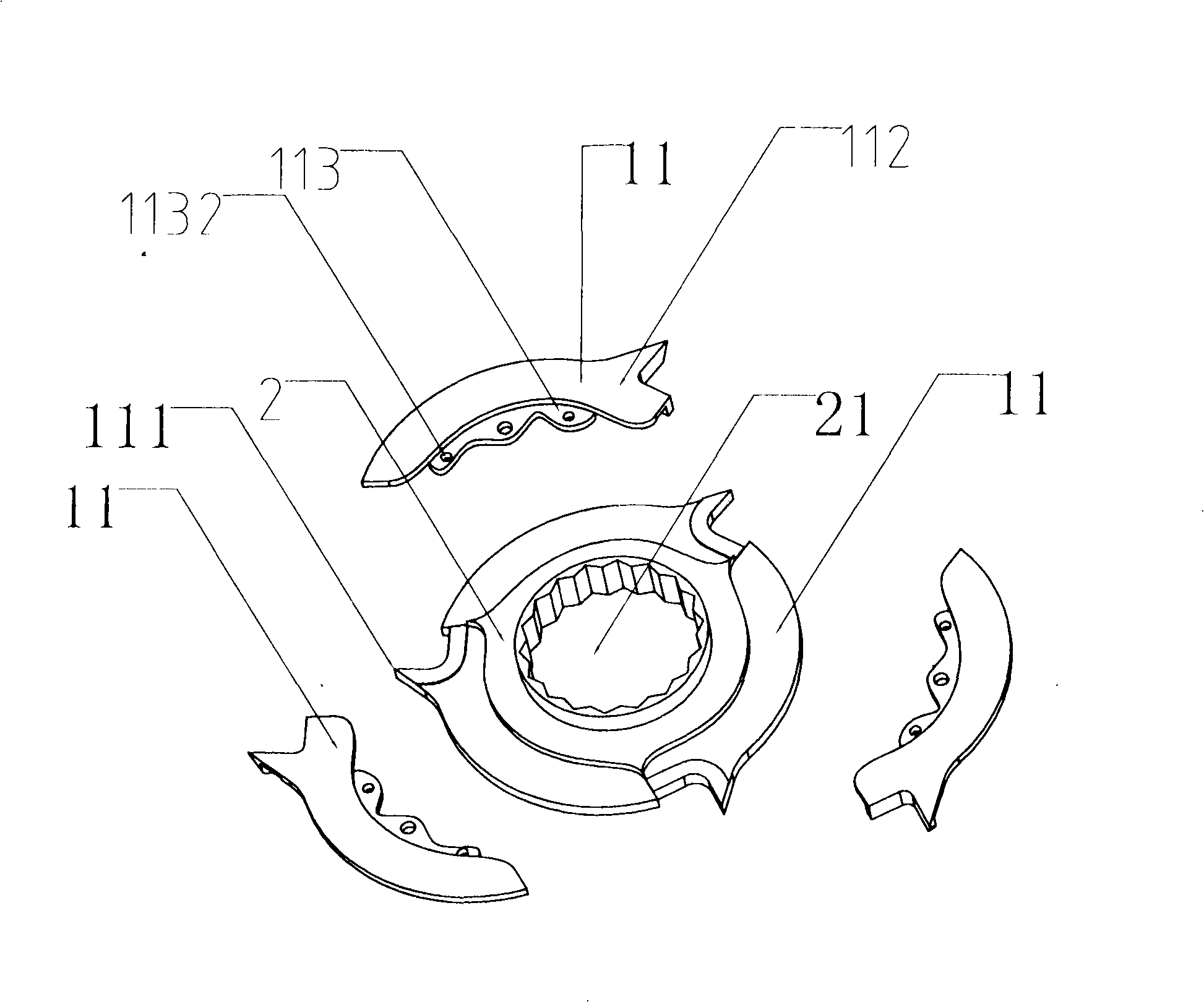

[0038] Such as figure 1 , figure 2 ,with image 3As shown, a paper shredder composite structure blade, including a blade (1) with a cutting edge (111) on the periphery and a base ring (2) inside, the center of the base ring (2) is compatible with various shapes The shaft center hole (21) fitted with the shaft rod, wherein, the blade (1) is made of metal material, the base ring (2) is made of polymer material, the blade (1) and the base ring ( 2) Combined into one body by injection molding, the blade (1) is composed of multiple segments of arc-shaped blades (11) that can surround the base ring (2), and the multiple segments of arc-shaped blades (11) are continuous and complete original blades (1) Separate along a certain breaking point (13) on the periphery of the original blade, the breaking point (13) is located below the cutting edge (1111) of the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com