Simple fixture for manual PCB debugging

A PCB board and fixture technology, applied in the field of simple fixtures for manual PCB debugging, can solve problems such as cost waste, inconvenient operation and use, and complex structure, and achieve the effect of avoiding contact testing and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

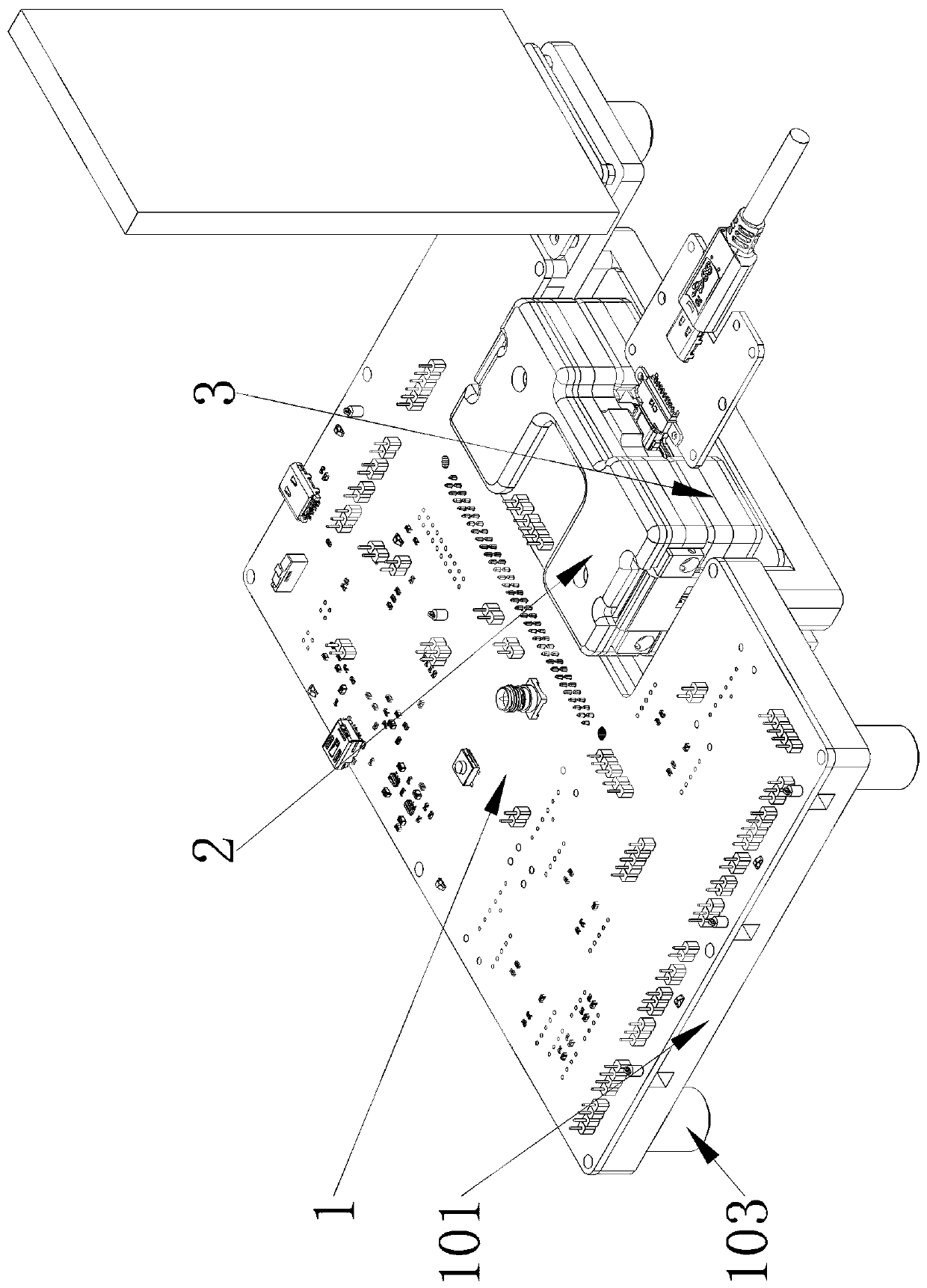

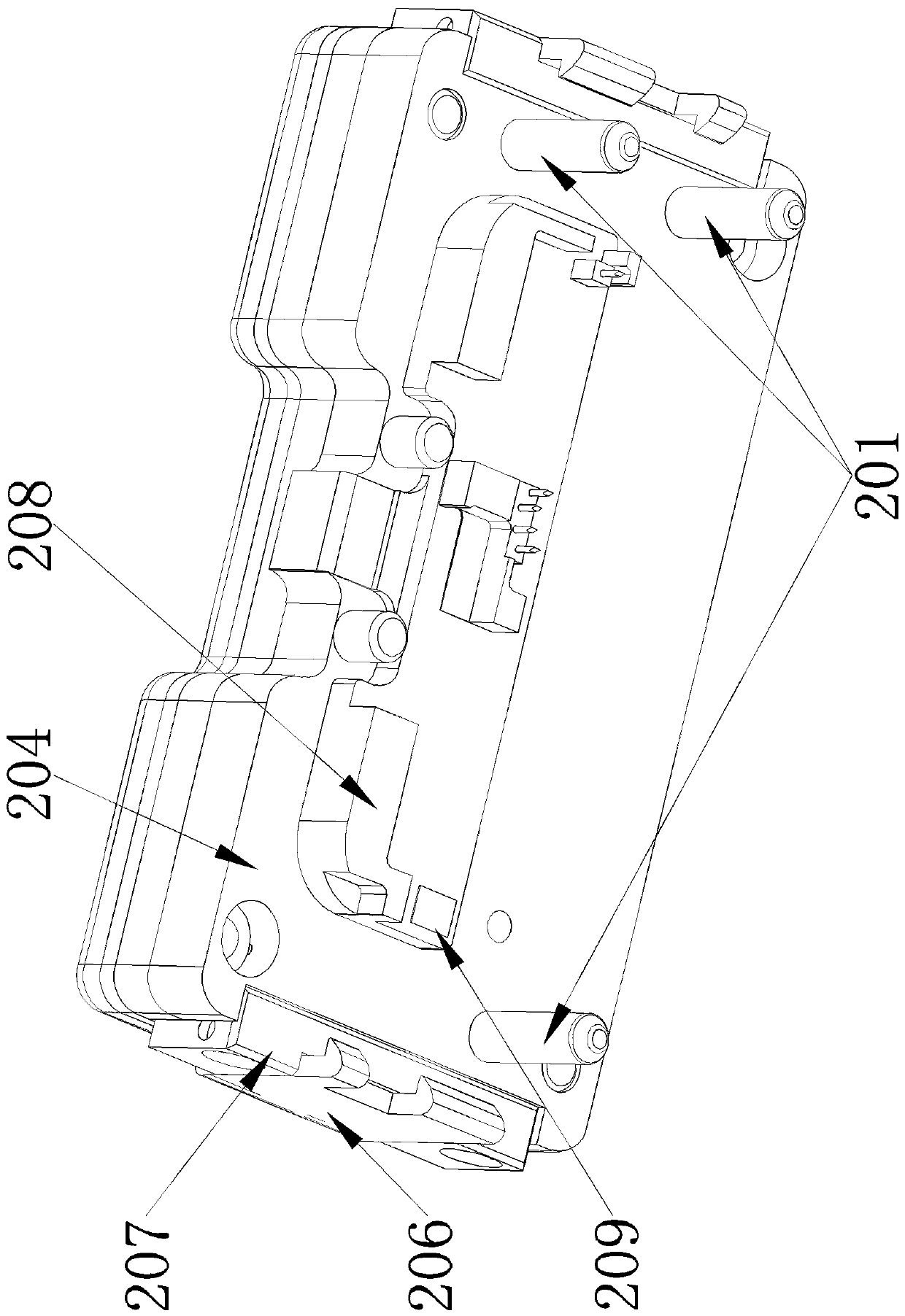

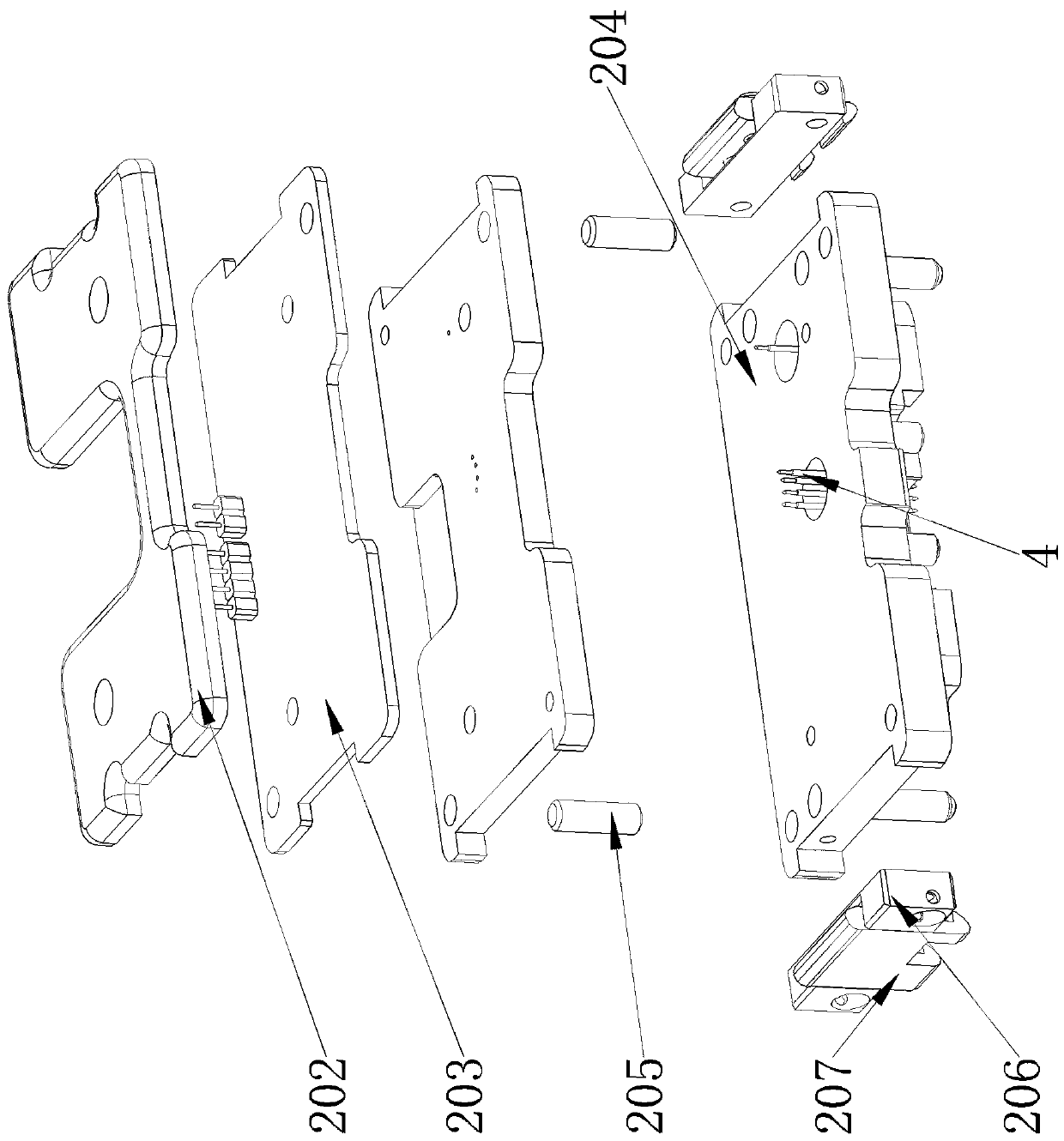

[0031] Such as Figure 1 to Figure 6 As shown, in this embodiment, the present invention includes a debugging board 1, an upper needle board 2 and a lower needle board 3, and several probes 4 are arranged on the upper needle board 2 and the lower needle board 3, and several The probes 4 are all electrically connected to the debugging board 1, the lower needle board 3 is fixedly matched with the debugging board 1, the lower needle board 3 is provided with a product placement groove 301, and the upper needle board 3 is provided with a product placement groove 301. The needle plate 2 is connected with the lower needle plate 3 through a buckle structure. When the upper needle plate 2 is connected with the lower needle plate 3, the probe 4 is placed in the product placement groove 301 The PCB board to be tested is contacted and electrically connected, and the debugging board 1 is provided with a display for displaying test data.

[0032] In this embodiment, the display is an LCD d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com