Cured plane-interlocking stereo-stacking engineering block and production method thereof

A technology of solidification molding and production method, applied in coastline protection, building components, construction, etc., can solve the problems of inability to absorb industrial waste engineering slag, simple product structure, small product specifications, etc., and achieve excellent freeze-thaw resistance characteristics, Low production cost and small drying shrinkage coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

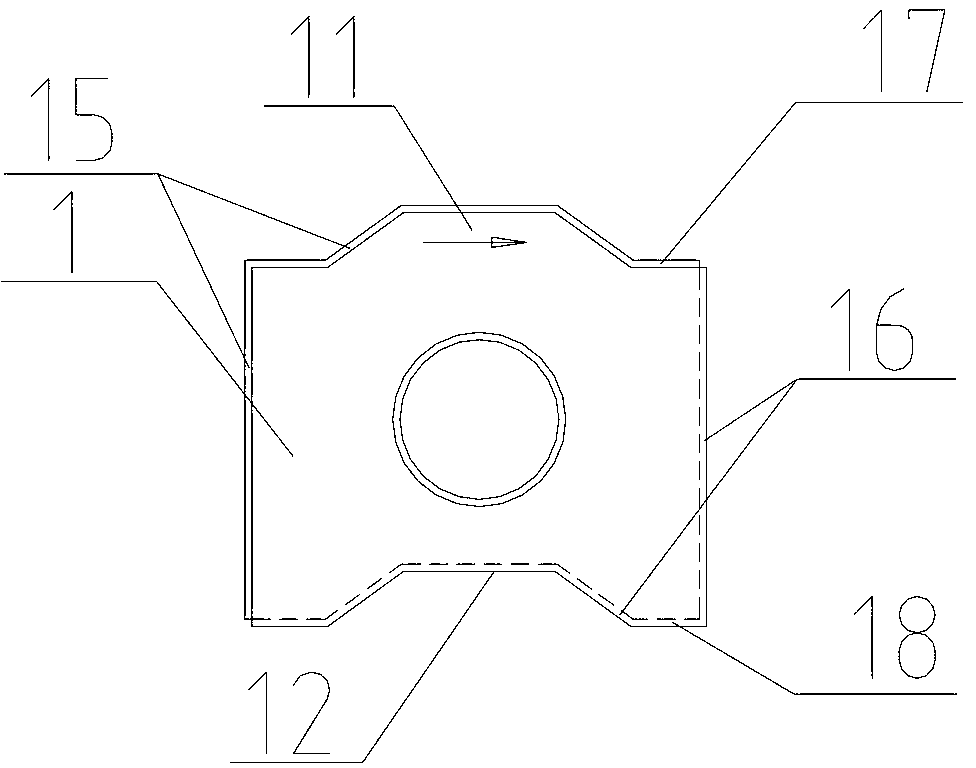

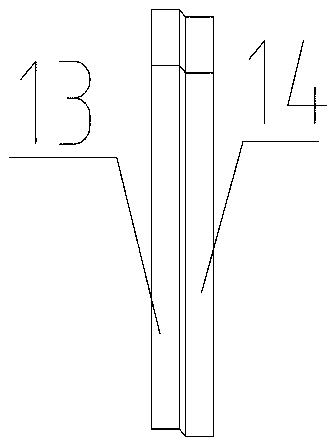

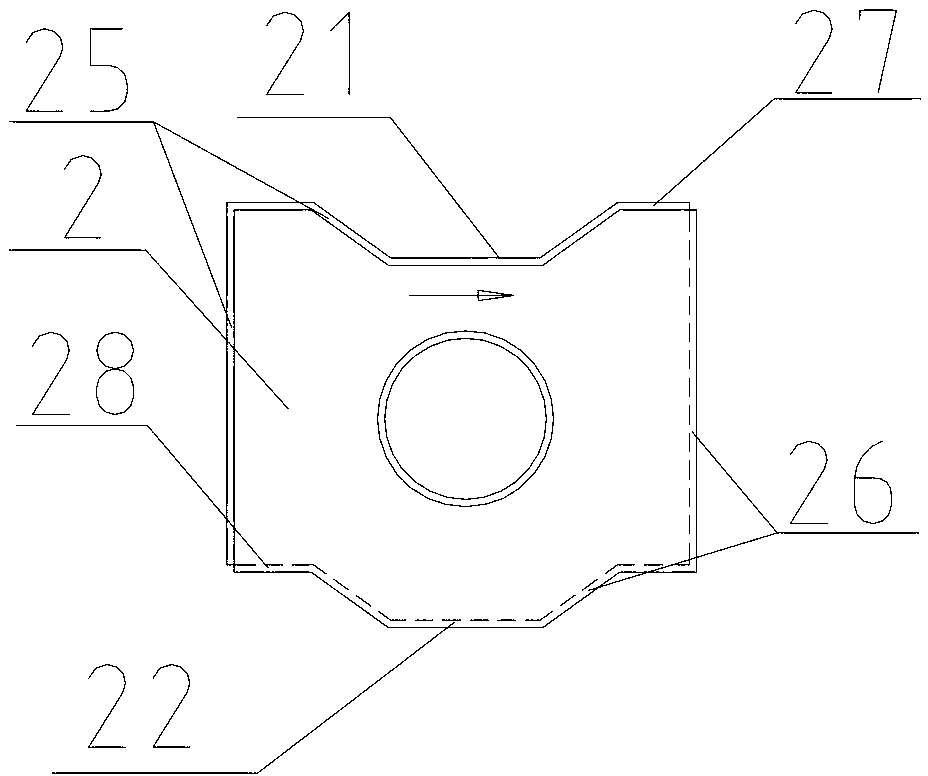

[0063] Such as Figure 1-12 As shown, a solidified and formed plane interlocking three-dimensional overlapping engineering block includes: left bank convex block 1, left bank concave block 2, right bank convex block 3, right bank concave block 4 and lining strip 5;

[0064] The left bank convex block 1 is a flat cuboid, the left bank convex block 1 is provided with a raised part 11 in the middle of the front part, and a groove part 12 is provided in the middle of the rear part. 1 includes: an upper layer body 14 and a lower layer body 13; the upper layer body 14 is arranged above the lower layer body 13, and the front side of the left bank convex block 1 and the lower layer body 13 on the left side are arranged There is an extension protrusion 15, and the side of the upper layer body 1 14 on the right side and the rear side is provided with an extension protrusion 2 16;

[0065] The left bank concave block 2 is a flat cuboid, the left bank concave block 2 is provided with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com