Thin-layer composite tissue repair material with stable mechanical property and preparation method thereof

A technology of composite tissue and repair materials, applied in medical science, prosthesis, etc., can solve the problems of bacterial colonization, infection, and incomplete fit, etc., and achieve the effect of mild tissue reaction, good biocompatibility, and good integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

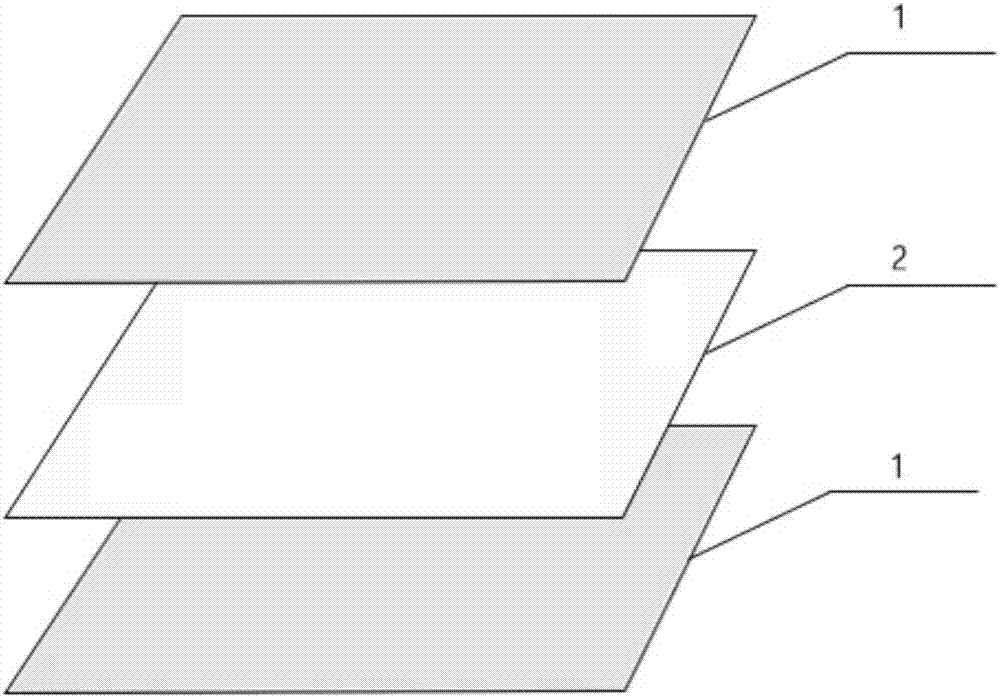

[0027] The pig small intestinal submucosa extracellular matrix (SIS) was prepared by the Abraham method, and the single-piece membrane-like SIS was spliced into a larger-area sheet according to the dislocation between the layers, and three layers were tiled, and they were bonded together with medical adhesives , for the upper and lower surface layers. The porosity is 80%, the average pore size is 10μm, and the mass is 30g / m 2 electrospun fabric. like figure 1 Place the upper and lower surface layers (1) and the electrospun cloth (2) in sequence, and the mass ratio of the upper and lower surface layers to the electrospun cloth is 10:1. Bond the three with medical adhesive, and then press them together with a certain pressure.

Embodiment 2

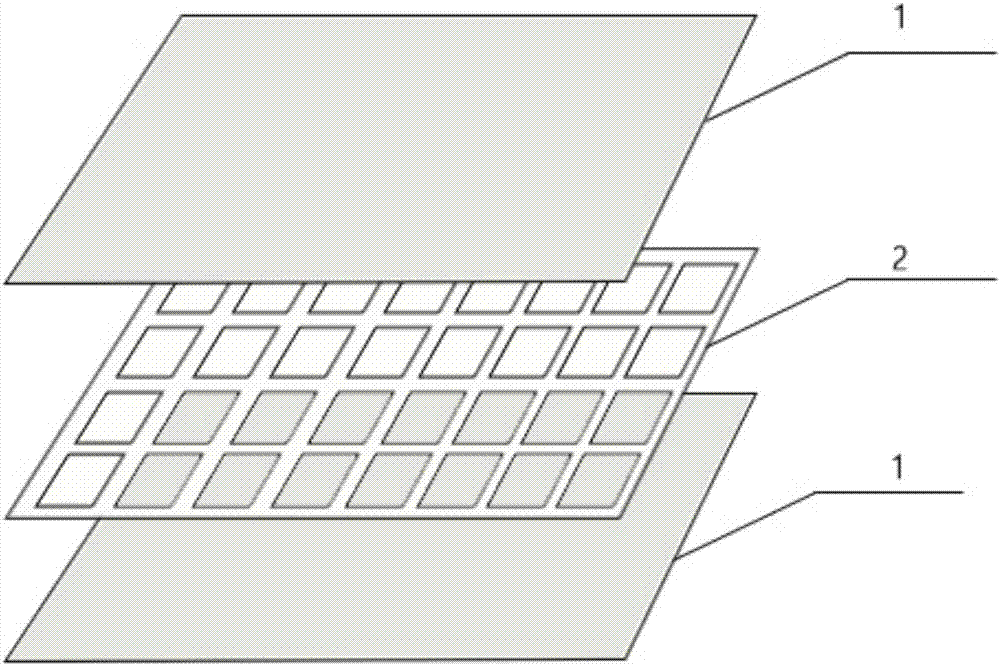

[0029] The single film-like SIS is spliced into larger-area sheets according to the dislocation between layers, three layers are tiled, and the upper and lower surface layers are bonded together with medical adhesives. The square hole is 1cm long, the hole spacing is 1mm, and the mass is 30g / m 2 brushed polypropylene film. like figure 2 Place the upper and lower surface layers (1) and the film (2) in sequence, and the mass ratio of the upper and lower surface layers to the film is 10:1. Bond the three with medical adhesive, and then press them together with a certain pressure.

Embodiment 3

[0031] According to the national standard GB / T528-2009, five samples of each of Example 1 and Example 2 were made into a 5cm×1cm dumbbell shape, and the two ends of the sample were fixed with a material mechanics testing machine, stretched at a speed of 10mm / min, and the material resistance was measured. The tensile strengths were 63±7N / cm and 54±5N / cm respectively.

[0032] Construct an animal model of canine rectus abdominis partially layered defect with local high pressure (a water bladder is added between the posterior sheath of the rectus abdominis and the repair material), and the defect area is 10×5cm2 , the composite biological patch was cut to a certain size for repair, and the tension was increased to 40mmHg by injecting water into the water bag monthly after the operation. It was observed that there was no abdominal wall bulge in the repaired area at 24 months; the tissue in the repaired area was taken out at 24 months after the operation, and the mechanical strength ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bursting strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com