Fabric cutting device capable of preventing scattering of weaved watchband and difficult in machining process

A cutting device, an uncompromising technology, applied in fabric surface trimming, textile material cutting, textile and paper making, etc., can solve problems such as easy to scatter, different drill sizes, and scatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] as attached figure 1 to attach Figure 6 Shown:

[0028] The invention provides a cloth cutting device which prevents the braided watchband from being unraveled and difficult to process.

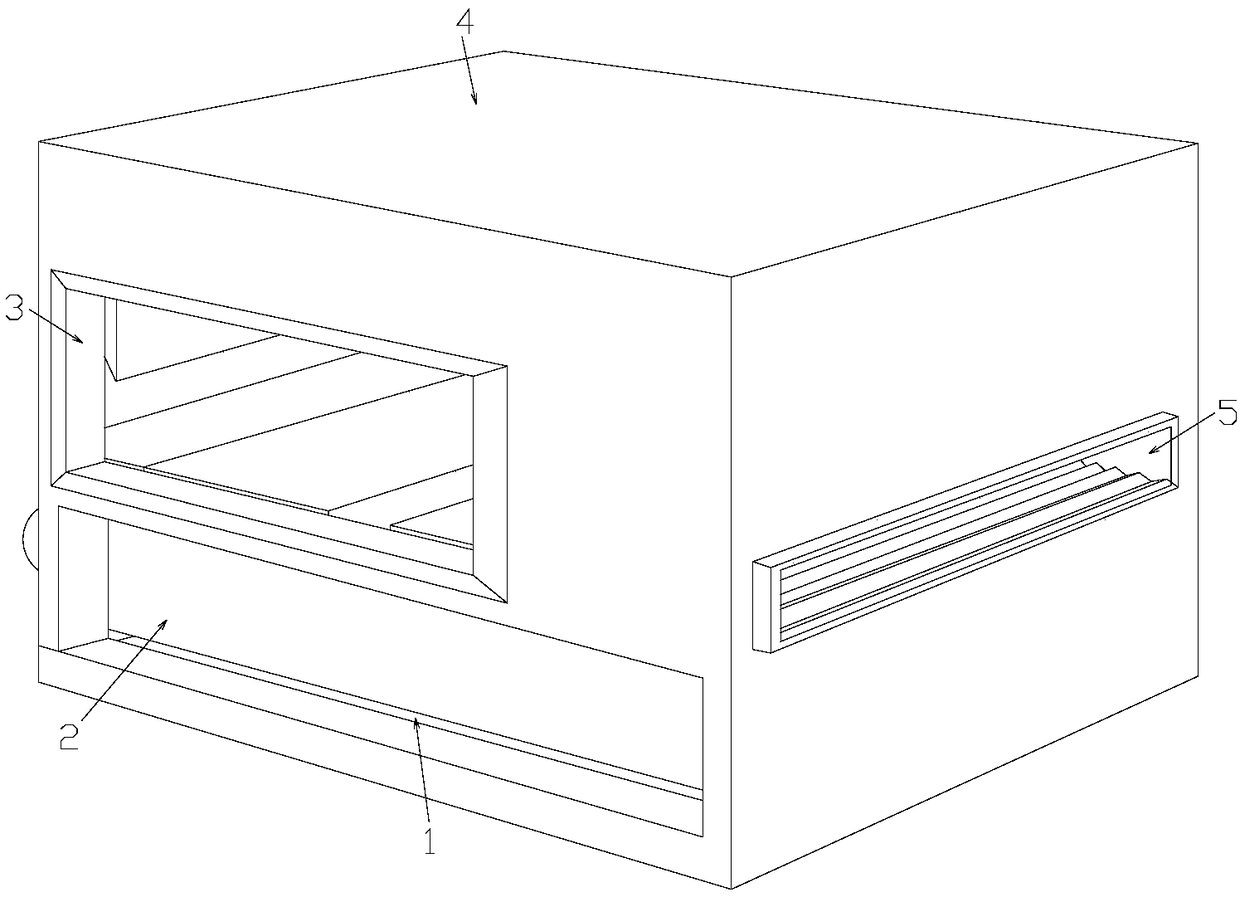

[0029] The moving grid 1 is installed at the inner bottom of the operating operation box 4, the moving placement slot 2 is located in the inner groove of the moving grid 1 and is flexibly connected, and the observation windows 3 are provided with two and embedded in the two ends of the operating operating box 4 Inside, the redundant outlet port 5 runs through one end of the operating box 4 and communicates with each other.

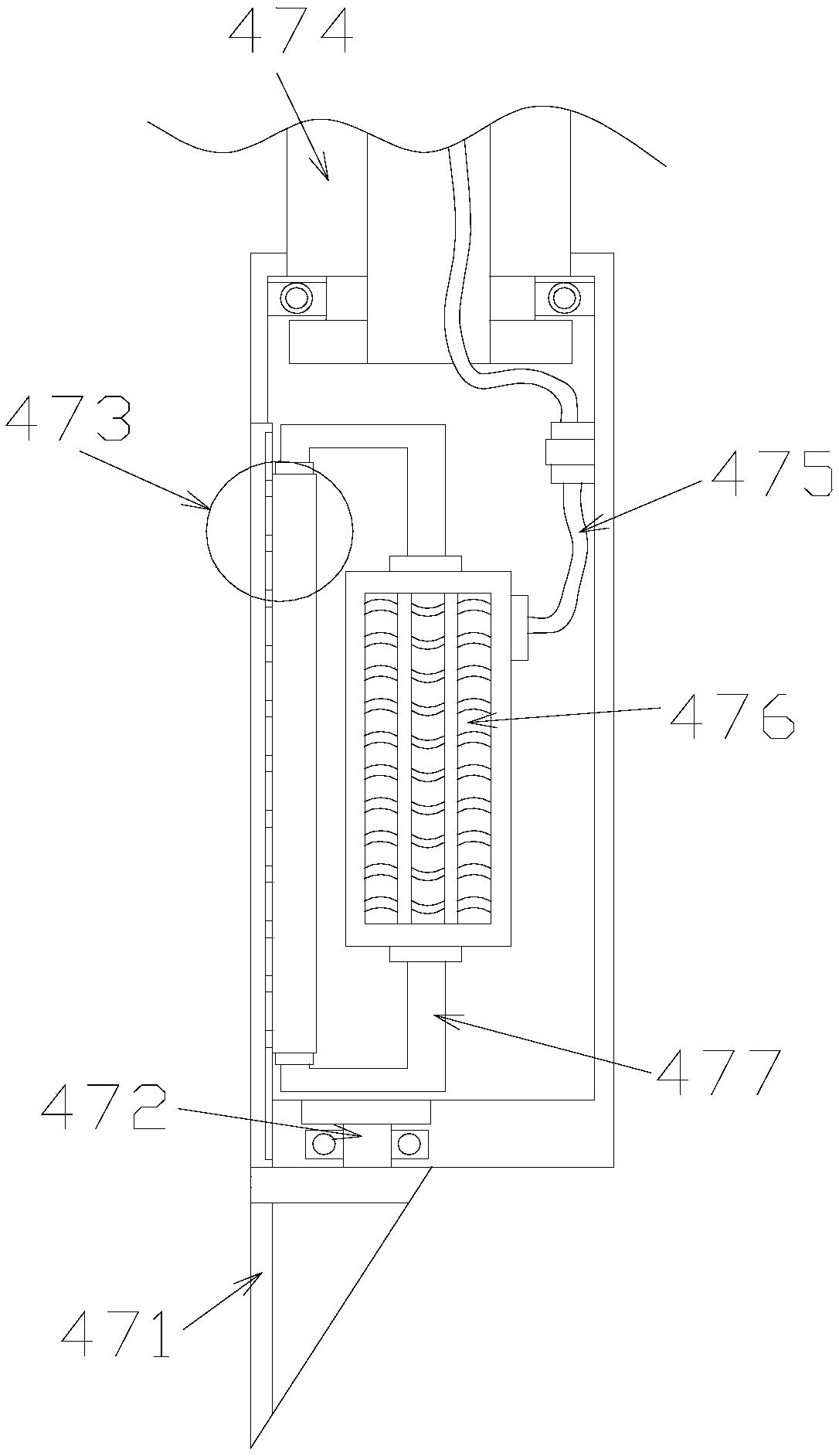

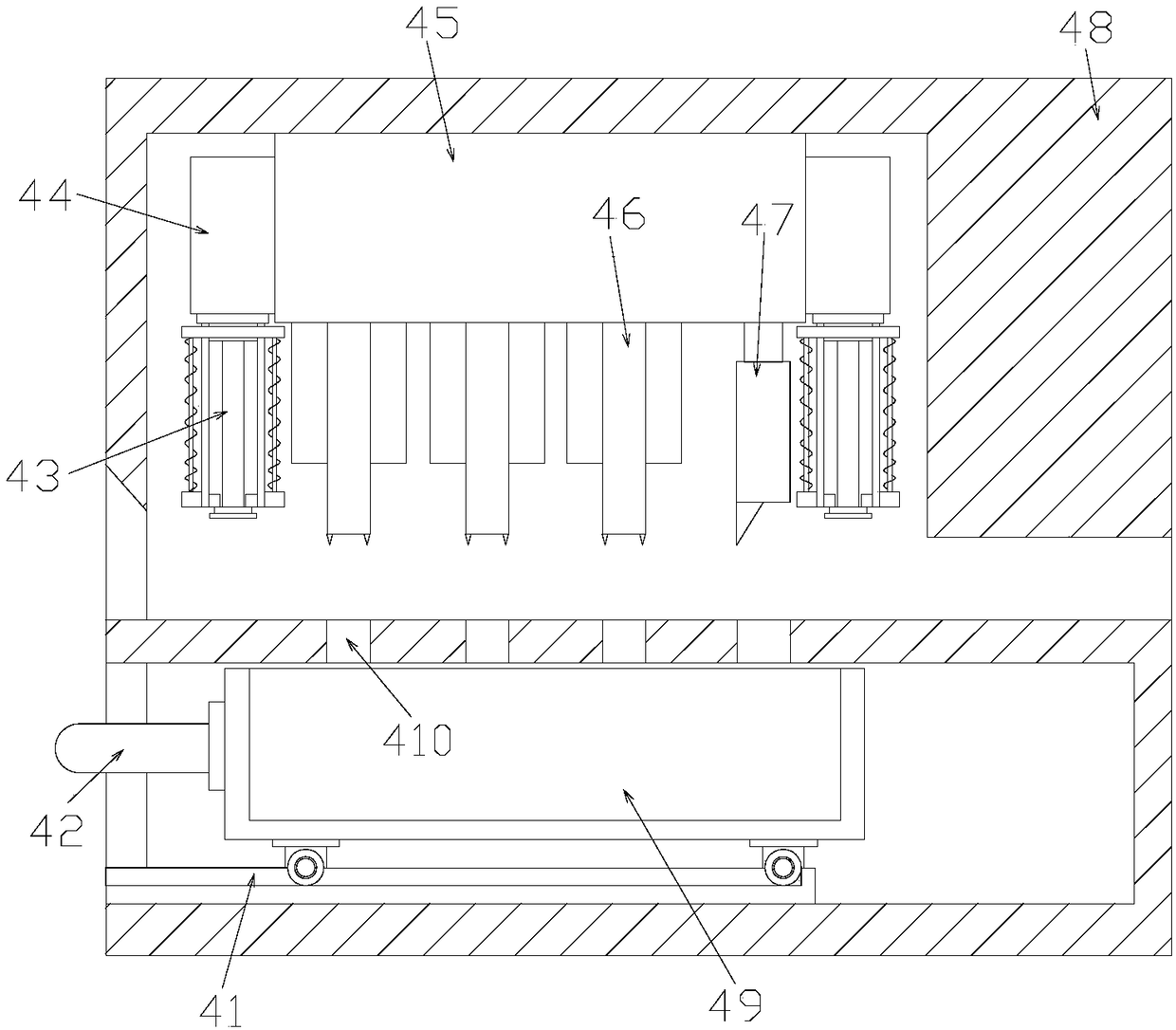

[0030] The running operation box 4 includes a slide rail 41, a handle 42, an extrusion fixing group 43, an extrusion control box 44, a main control box 45, a rotary cutting edge banding device 46, a cutting and hot sealing equipment 47, a protective shell 48, and Grid 49, hollow space 410, described hollow space 410 is arranged on the bottom of rotary cutting e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com