Bagged spring bed core connected with band-shaped material on side surface and manufacturing device and method thereof

A pocket spring and manufacturing device technology, applied in the field of pocket spring bed core and its manufacturing device, can solve the problems of complex production process, high cost, poor durability of pocket spring bed core, etc., achieve good dimensional stability, production High efficiency and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

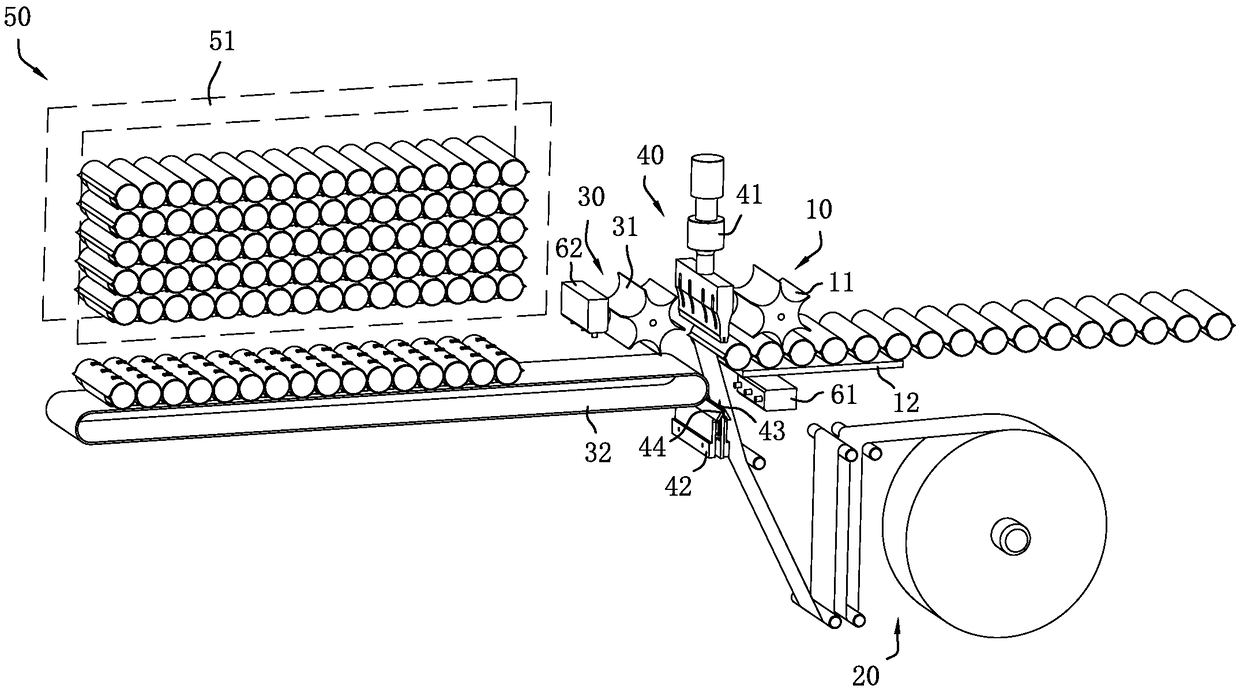

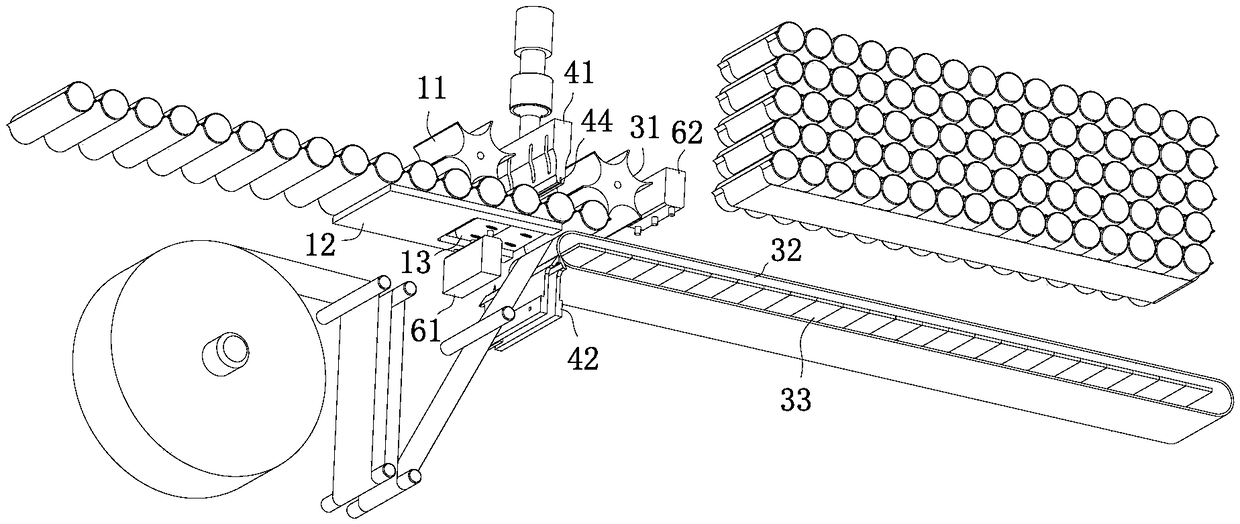

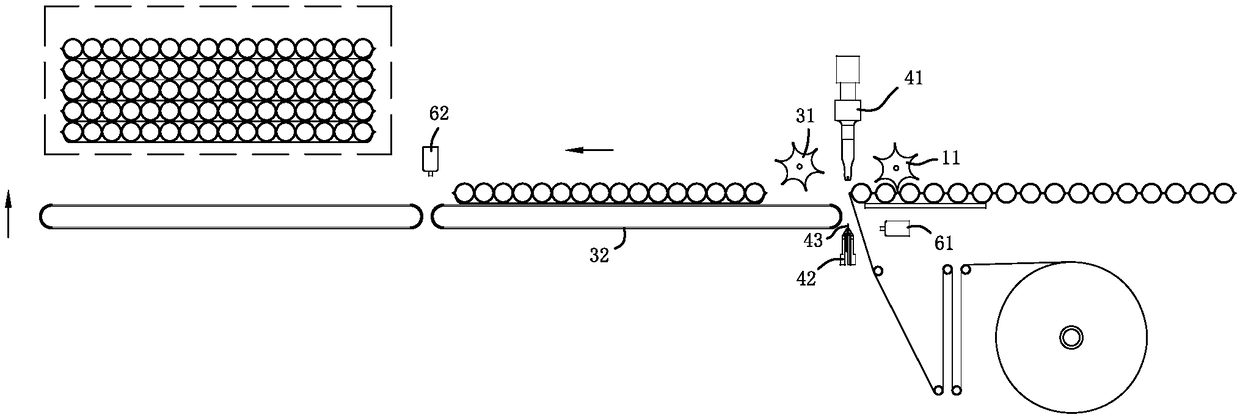

[0042] refer to figure 1 and image 3 , the present invention side is connected with the bag spring bed core of strip-shaped material and manufacturing device thereof, comprises string feeding mechanism 10, material feeding mechanism 20, finishing mechanism 30, sealing and cutting mechanism 40, combination mechanism 50. The string feeding mechanism 10 and the sorting mechanism 30 are arranged oppositely front and rear, the sealing and cutting mechanism 40 is arranged between the string feeding mechanism 10 and the sorting mechanism 30, the combination mechanism 50 is arranged behind the sorting mechanism 30, and the feeding mechanism 20 is arranged below the string feeding mechanism 10.

[0043] Wherein, the string sending mechanism 10 is used for conveying continuous pocket spring strings into the finishing mechanism 30, specifically, the string sending mechanism 10 includes a string sending impeller 11 positioned above and a bracket 12 positioned below, and the string sendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com