Sewing technology of sewn products, processing equipment and sewn products processed by processing equipment

A processing equipment and sewing technology, applied in the fields of sleeping bags, bags and clothing, which can solve the problems of labor-intensive and labor-intensive manual operation reliability and consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0148] A method and device for making a sleeping bag:

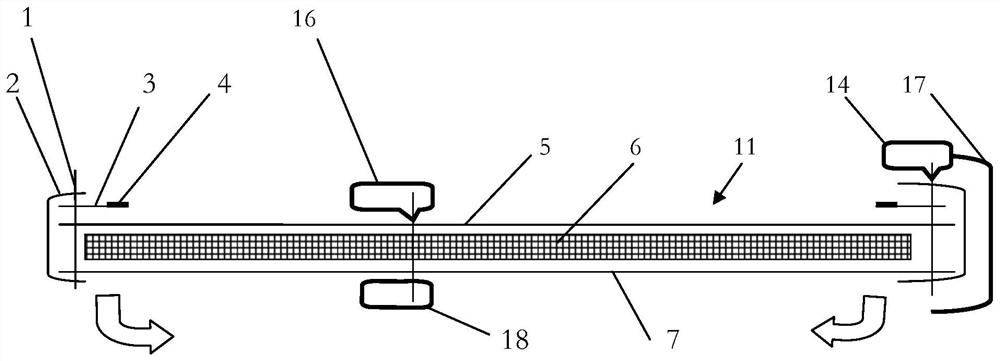

[0149] Such as figure 1 As shown, the fabric 5, filling material 6 and lining 7 of the sleeping bag are superimposed together, and sent to the sewing head 16 including the quilting machine for sewing, so that the three are integrated into the body of the sleeping bag. Product 11.

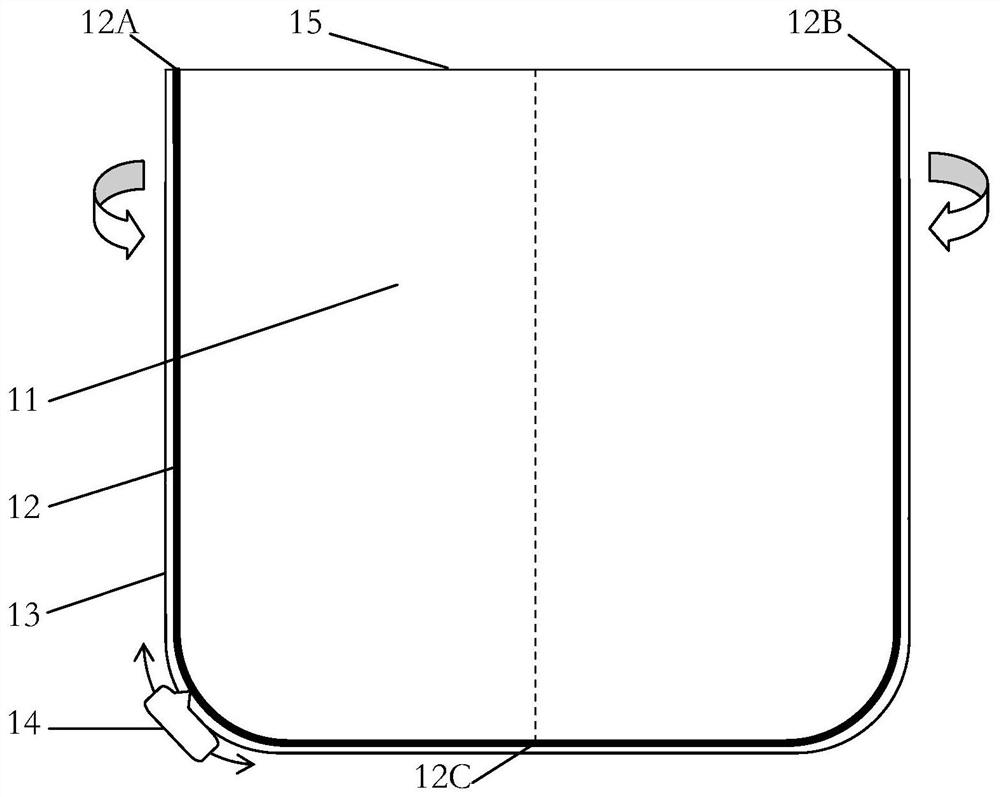

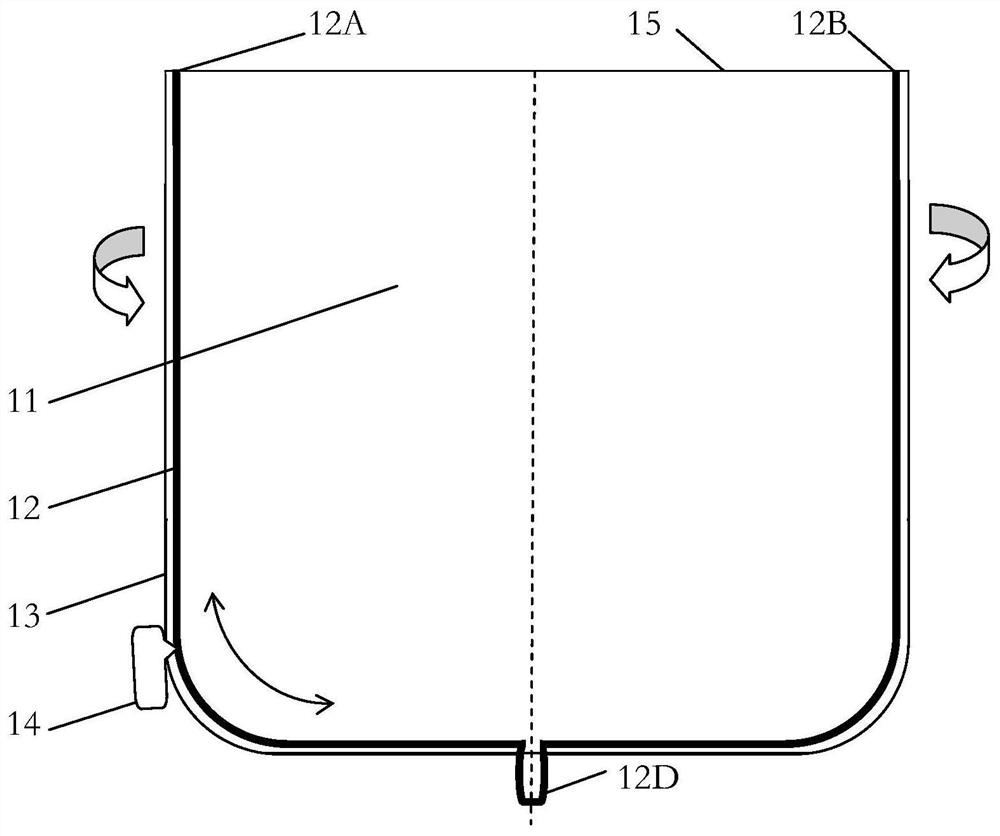

[0150] Then the three connected into one (body first product 11) are cut out to meet the edges of the pre-designed shape. For example, figure 2 and image 3 Shown rectangular edge (certainly, also can be other such as mummy shape, ellipse, coke bottle shape, even irregular special-shaped edge, as long as can realize computer precise control all can).

[0151] Then again figure 1 and figure 2 (or image 3 ) shown, the fracture of the edge of the first body product 11 is hemmed with the hemming cloth 2 by the hemming machine head 14. At this time, the fractures of the fabric 5, the filling material 6 and the lining 7 are all wrapped b...

Embodiment 2

[0166] The hemming in the above embodiment 1 is a single hemming structure. In order to prevent the edges of the binding cloth 2 from being scattered, it can also be used as Figure 5 As shown, the hemming is made into a double hemming structure. Described sleeping bag making equipment can be as Figure 18 to Figure 23 As shown, it can be obtained by modifying and installing the quilting machine with very mature and reliable technology.

[0167] Such as Figure 5 As shown, the fabric 5 of the sleeping bag, the filling material 6 (mainly shaped cotton based on sprayed cotton) and the lining 7 are superimposed in order and then sent to the quilting mechanism for quilting of the first body product 11 ( For avoiding trivial details, the quilting line) and / or the stitching of the edge of the unfolded shape of the sleeping bag are not shown in the figure.

[0168] Then, the edge fracture is cut open again, and then double-wrapped. That is, place the edge of the binding cloth 2 ...

Embodiment 3

[0173] During the pulling and closing process of a general sleeping bag zipper, it is easy to get the fabric 5 or lining 7 in contact with the slider of the zipper stuck in the slider. If the zipper head bites the lining and / or fabric of the sleeping bag into the zipper head and gets stuck, the zipper cannot be closed or the zipper is not smooth. To prevent this adverse phenomenon, you can Figure 6 As shown, a relatively harder or thicker anti-jamming strip 8 is added between the zipper cloth 3 and the hemming cloth 2 (or lining 7) during hemming.

[0174] The material of the anti-jamming strip 8 can be webbing, cloth or even a long plastic sheet, as long as its material is relatively hard or thick so that it is not easy to be stuck into the slider of the zipper.

[0175] The sleeping bag in the present embodiment presses Figure 6 Fold in half as indicated by the big arrows on the left and right sides of the middle and pull the zipper teeth 4 on the left and right sides to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com