Cement ground initial setting maintenance device

A ground and cement technology, which is applied in the field of cement floor initial setting maintenance devices, can solve the problems of reducing the life of the cement floor, reducing the quality of the floor, and sanding and dusting of the cement floor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

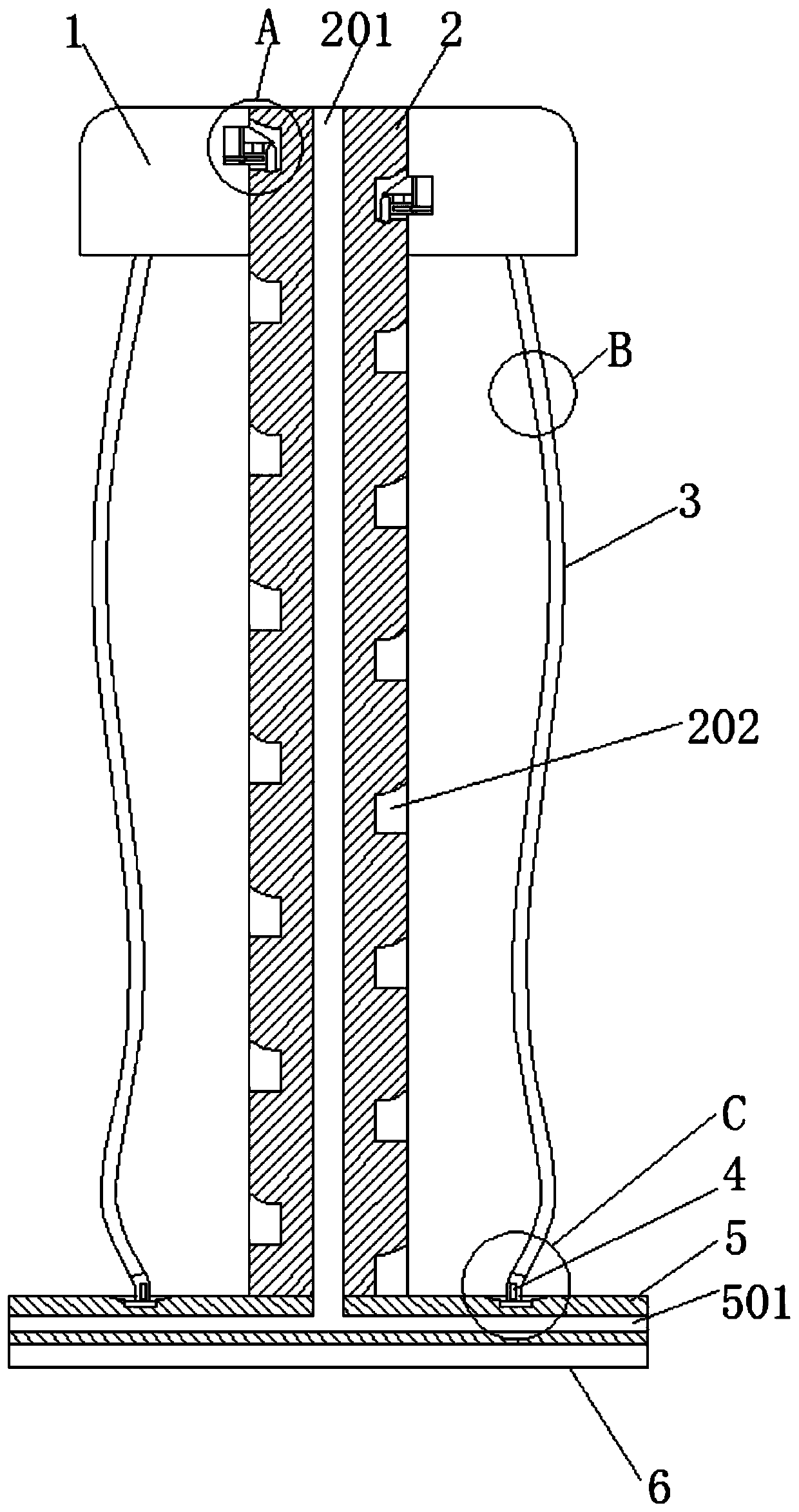

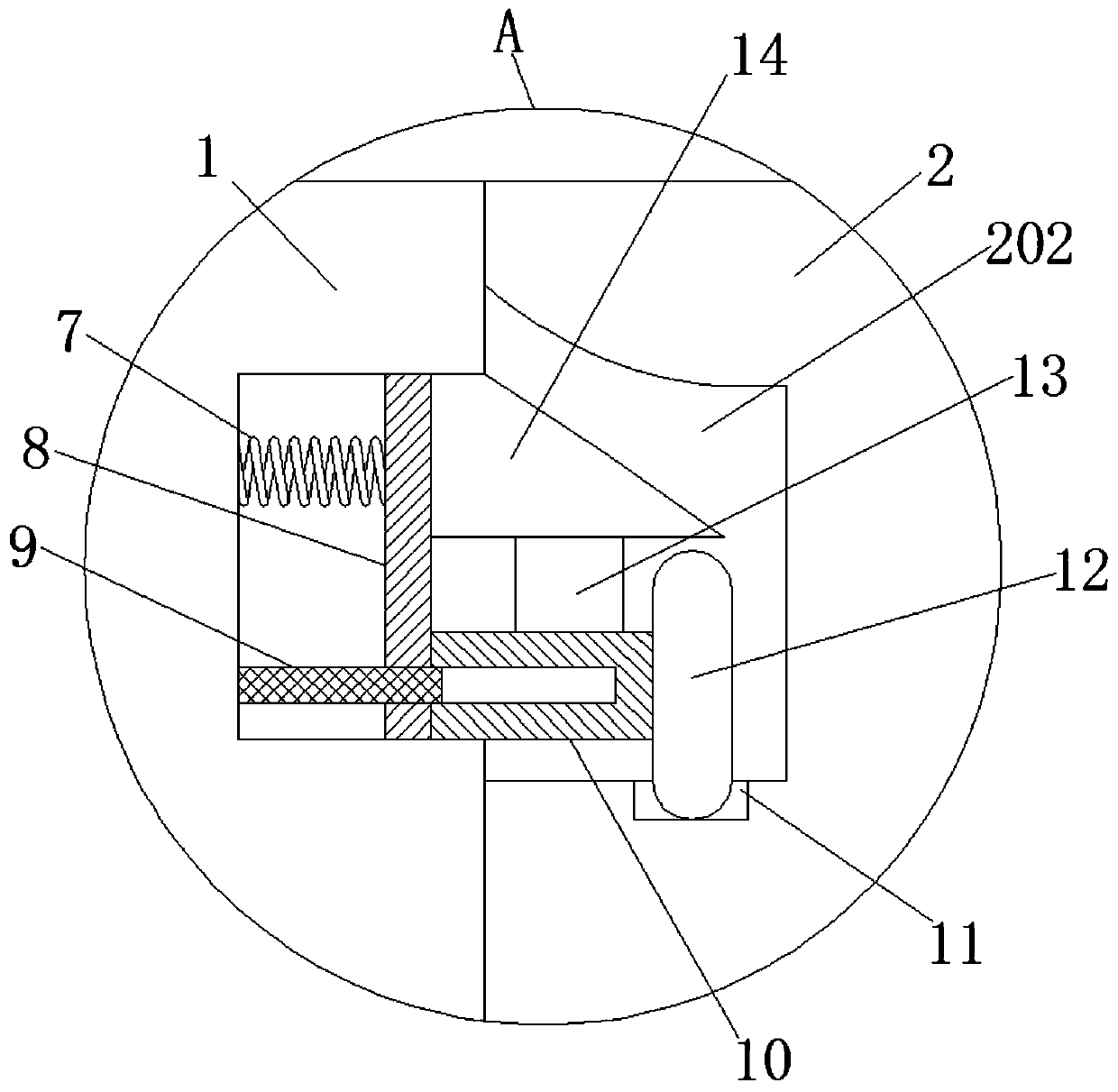

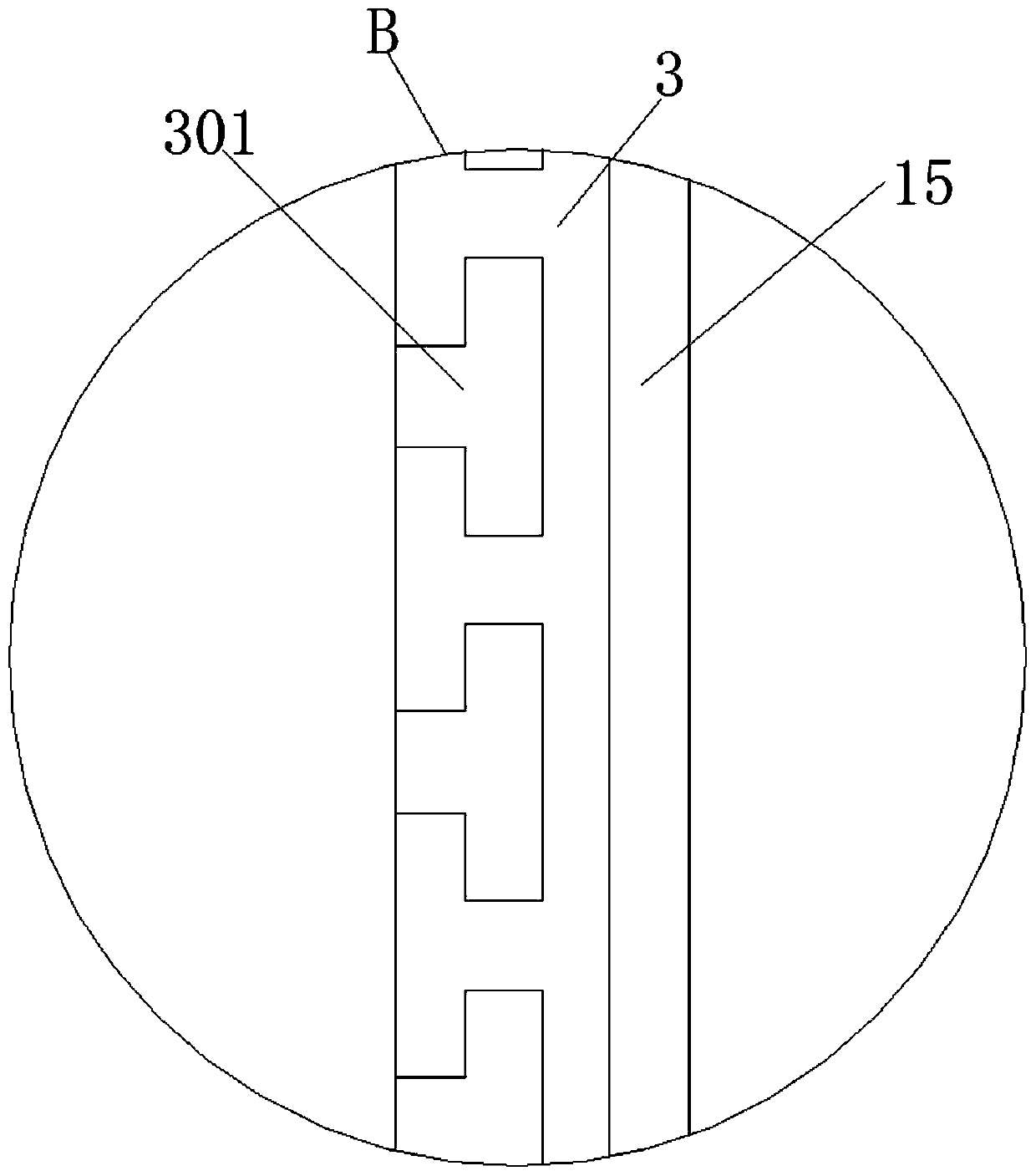

[0028] refer to Figure 1-5 , a cement floor initial setting maintenance device, comprising a main body 1, the middle part of the main body 1 is provided with a first through hole, the main body 1 is provided with a support column 2 at the first through hole, and the outer wall of the support column 2 is provided with a slideway 202, The slideway 202 is in a spiral shape. The main body 1 is provided with four first grooves equidistantly on the inner wall of the first through hole. The main body 1 is provided with a moving plate 8 at the first groove, and one end of the moving plate 8 is welded with a fixed shaft. 10. One end of the fixed shaft 10 is rotatably connected with a roller 12. The roller 12 is inside the slideway 202. The bottom end of the main body 1 is bonded with a water-absorbing film 3. The water-absorbing film 3 is ring-shaped, and the bottom end of the support column 1 is welded with a support plate. 5. There is a sponge pad 6 at the bottom of the support plat...

Embodiment 2

[0038] refer to Figure 6 , an initial setting maintenance device for cement ground. Compared with Embodiment 1, in this embodiment, in order to increase the practicability of the device and avoid the influence of cement condensation due to the low temperature of the construction environment, the top of the main body 1 is provided with a second annular concave Groove, the main body 1 is provided with a heating plate 17 at the second annular groove, a temperature sensor is provided on one side of the main body 1, the temperature sensor is electrically connected with the heating plate 17, a power line interface is provided on one side of the main body 1, and the temperature sensor The temperature of the surrounding environment can be detected, and when the surrounding construction environment temperature is lower than 7-8 degrees Celsius, the electric heater 17 can be started to increase the temperature of the surrounding construction environment, so as to avoid the low temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com