Manufacture method of large-diameter self-protection multi-strand stranded welding wire

A technology of multi-strand stranded welding wire and manufacturing method, which can be used in manufacturing tools, welding media, welding equipment, etc., and can solve problems such as end spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

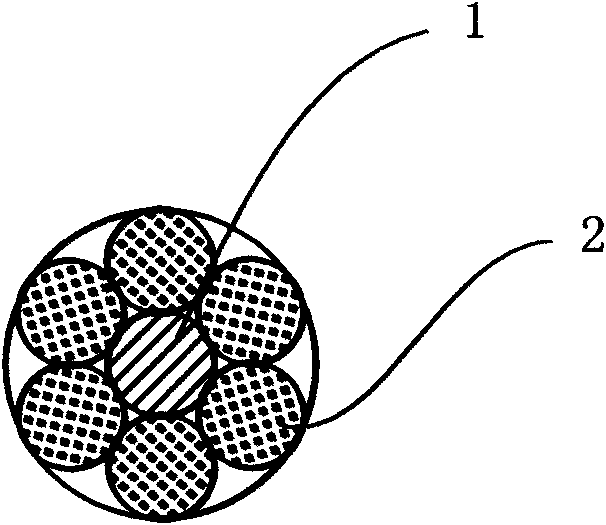

[0042] Such as figure 2 , image 3 As shown, the large-diameter self-shielding stranded welding wire manufactured by the manufacturing method of Embodiment 1 of the present invention is composed of a central solid welding wire 1 and 6 outer wound flux cores tightly wound on the central solid welding wire 1 Composed of welding wire 2, the diameters of the central solid welding wire 1 and the outer wound flux-cored welding wire 2 are both: 0.8mm; or 1.0mm; or 1.2mm.

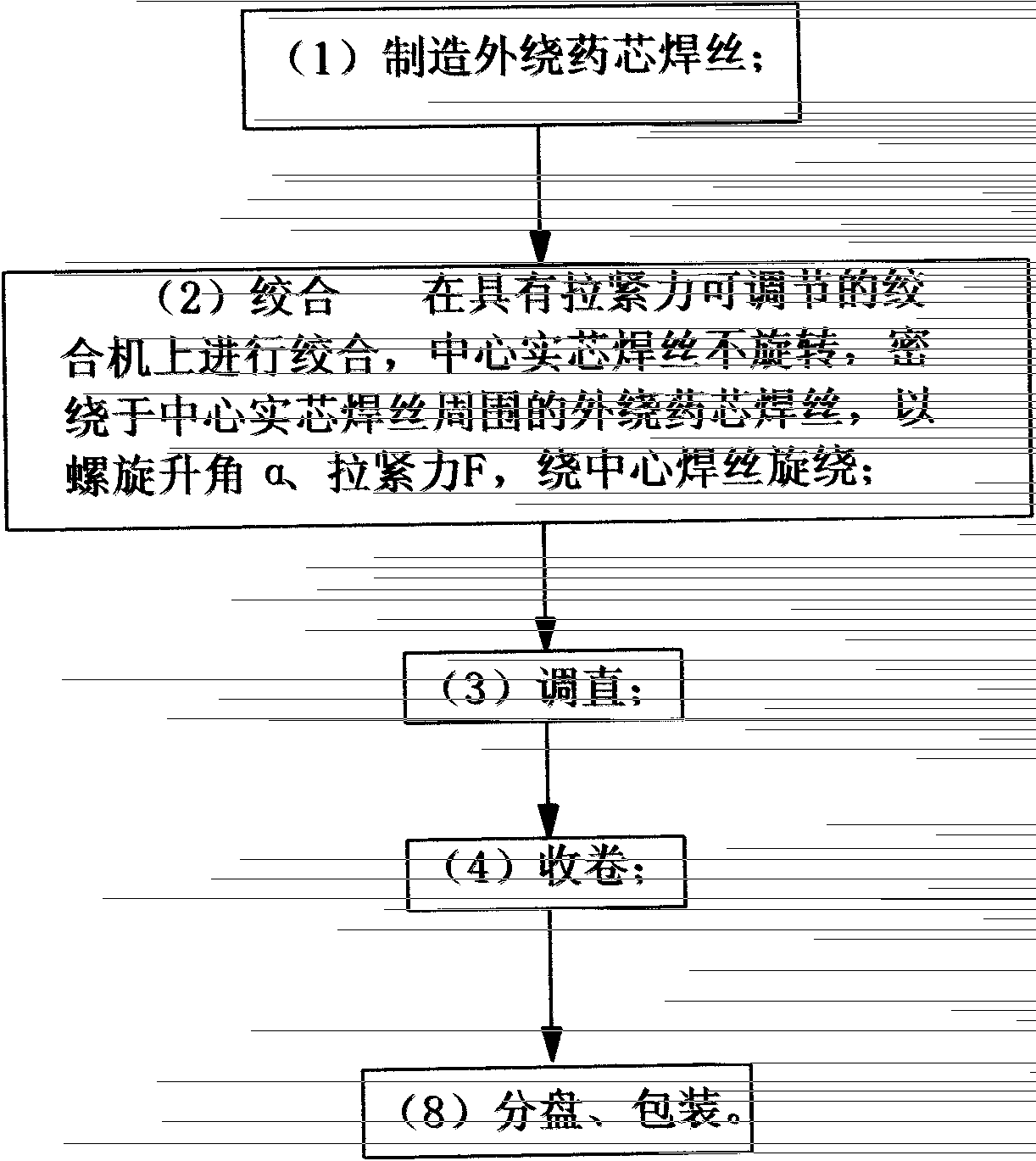

[0043] Figure 4 It is the production steps of the manufacturing method of the large-diameter self-shielding stranded welding wire of the present embodiment, including:

[0044] (1) Manufacture the outer wound flux cored wire, and manufacture it according to the conventional manufacturing method;

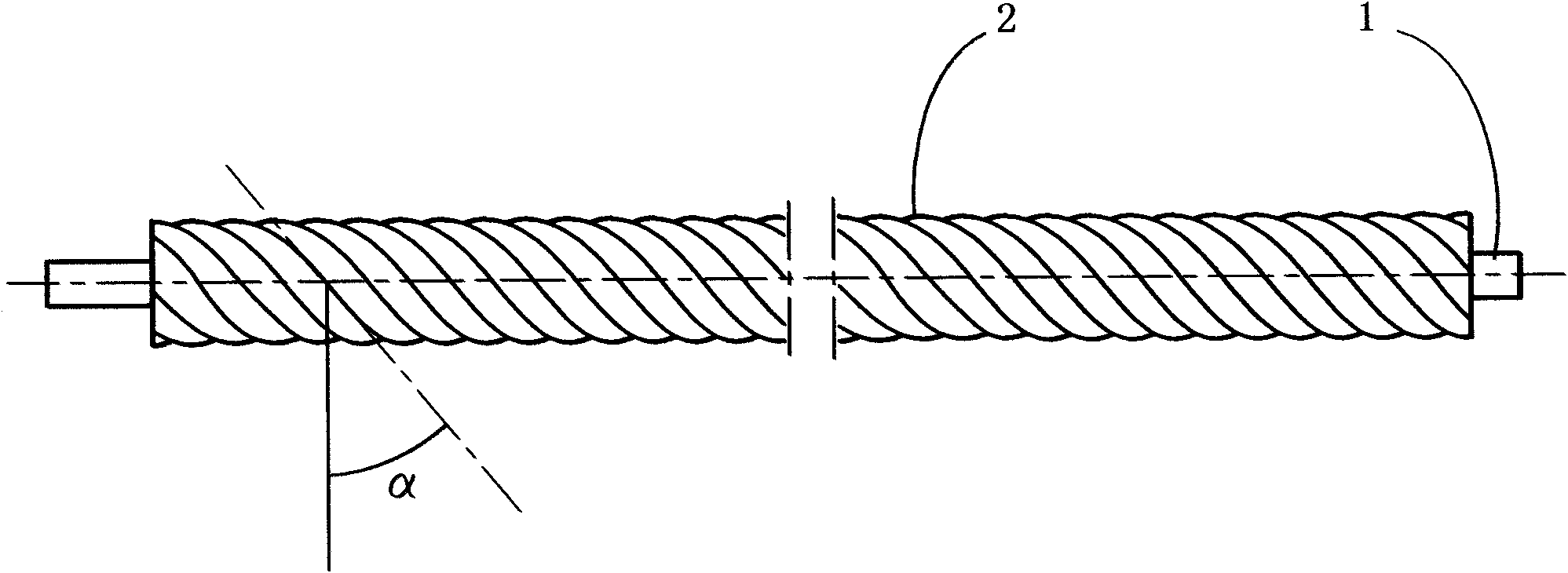

[0045] (2) Stranding is carried out on a stranding machine with adjustable tension. The central solid-core welding wire does not rotate. The tightening force F is wound around the central solid-cored wire; when the ...

Embodiment 2

[0050] Such as Figure 5 , Figure 6 Shown is that the large-diameter self-shielding multi-strand welding wire manufactured by the manufacturing method of the second embodiment of the present invention is composed of a central solid welding wire 1 and two layers of 18 outer layers tightly wound on the central solid welding wire 1. Composed of wound flux-cored welding wire 2, the diameters of the central solid-cored welding wire 1 and the outer wound flux-cored welding wire 2 are both: 0.8mm; or 1.0mm; or 1.2mm.

[0051] Figure 7 It is a production step diagram of Embodiment 2 of the manufacturing method of the large-diameter self-shielding stranded welding wire of the present invention. For the first layer of double-layer stranded welding wire, there are 6 outer-wound flux-cored welding wires that are tightly wound around the central solid-core welding wire; after winding, they are straightened and rolled; then wound on a twisting machine with adjustable tension In the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com