Pocketed spring unit and method and apparatus for forming the same

A pocket spring and compression spring technology, applied in the field of forming the pocket spring unit, can solve problems such as difficulty in recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

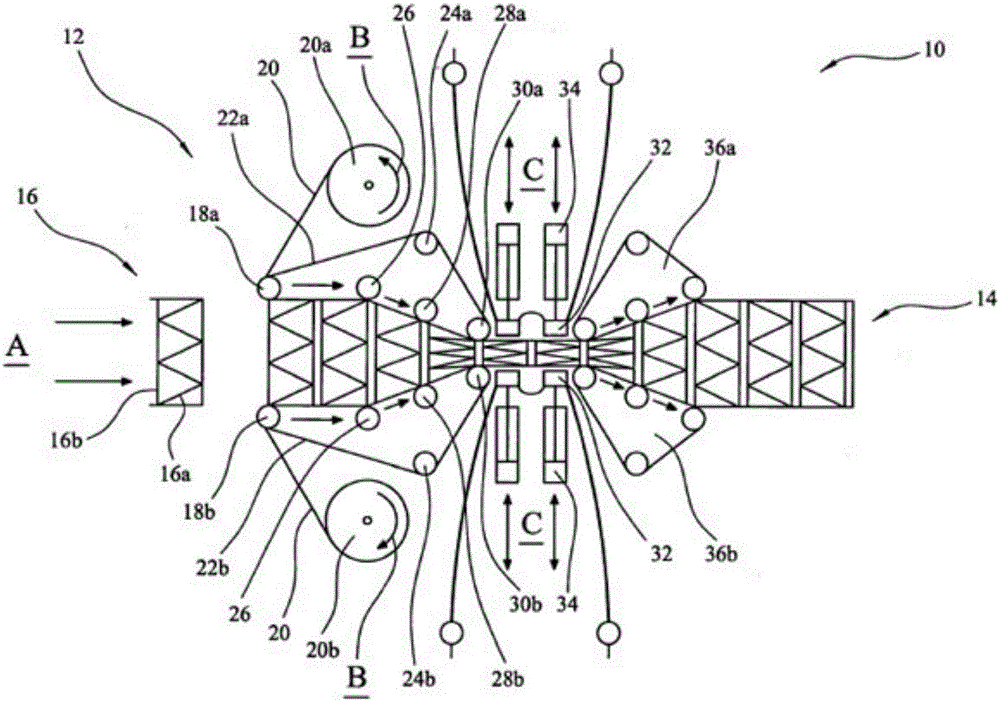

[0034] see figure 1 , which shows an apparatus, generally indicated at 10, for forming a pocket spring unit according to a preferred embodiment of the present invention.

[0035] The device 10 includes an inlet 12 and an outlet 14 . At the entrance, the pocket spring string 16 is shown terminated so that only the last spring is visible. Each spring comprises a coil 16a inside a separate pocket 16b formed of fabric material. The string 16 is fed in the direction of arrow A towards a first set of upper and lower pre-compression rollers, 18a and 18b respectively. At this point, fabric material 20 is introduced above and below the string of springs from fabric rolls 20a and 20b, which rotate in the direction of arrow B. FIG. Material 20 is fed around rollers 18a and 18b on belts 22a and 22b which are synchronously driven by drives 24a and 24b, respectively.

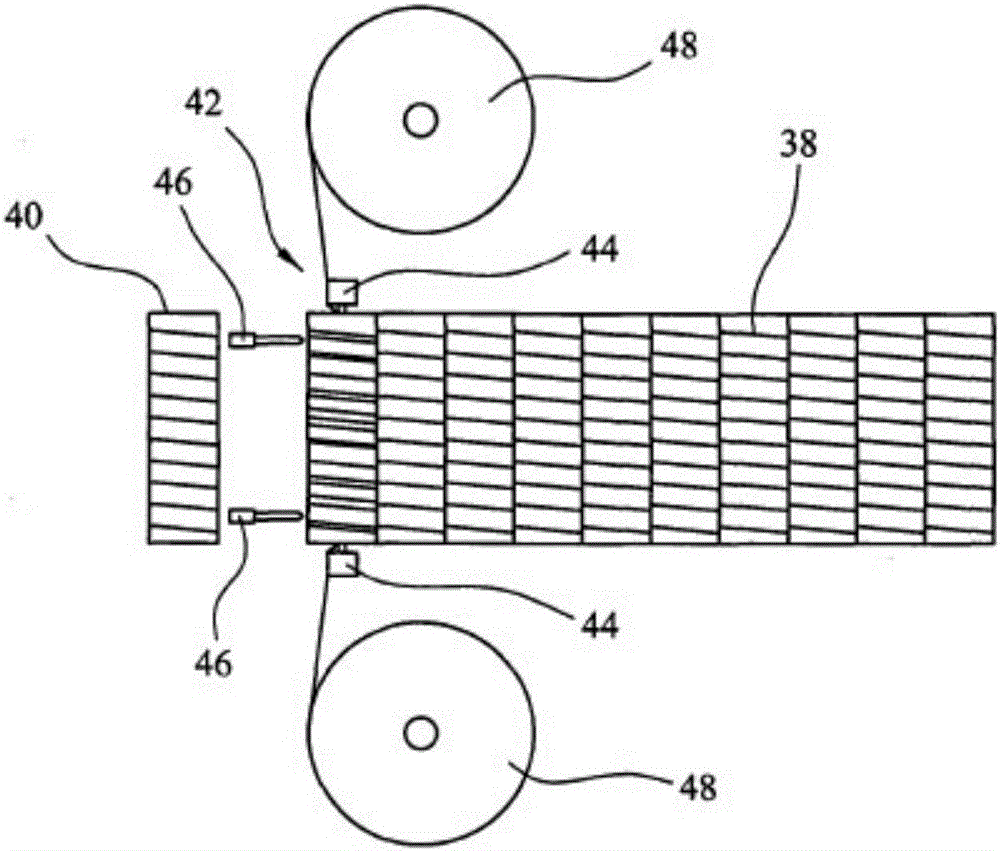

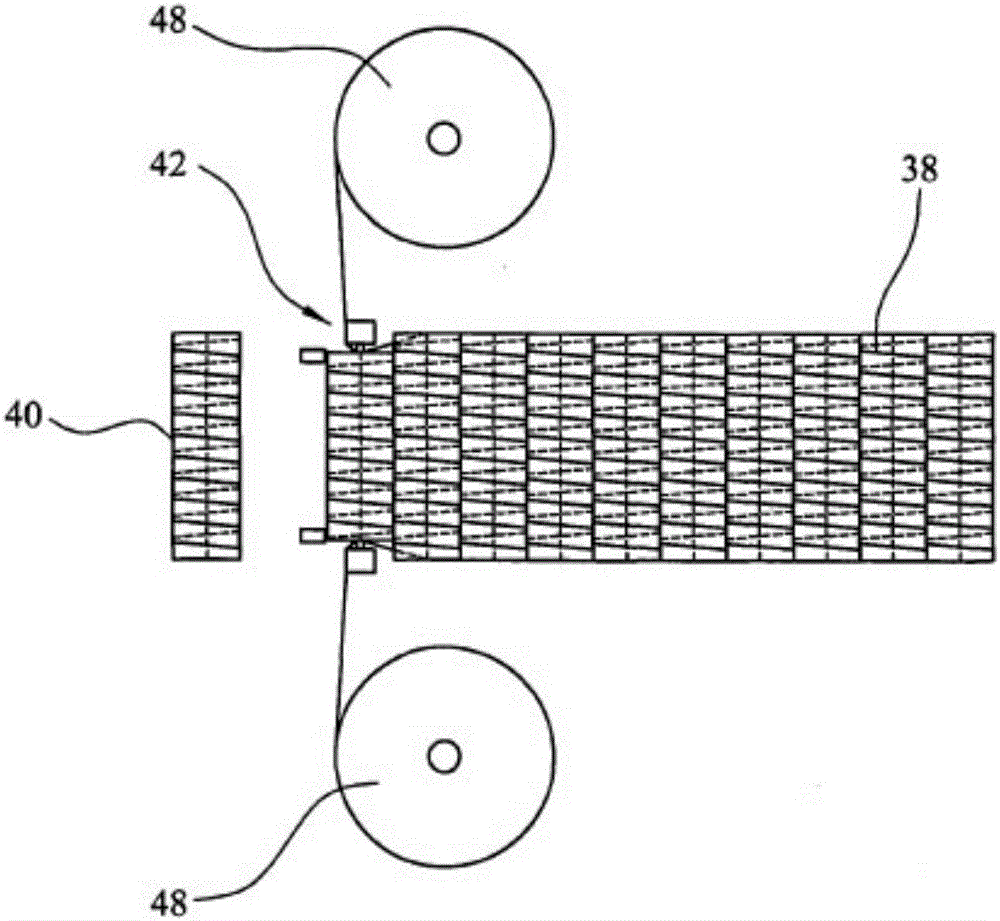

[0036] The uncompressed springs 16 abut each other and pass through the other pair of rollers 26 before reaching the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com