Infusion bag

An infusion bag and acrylic technology, applied in the field of infusion bags, can solve problems such as transparency, insufficient gloss, not being able to withstand bag drop, loss of softness, etc., and achieve excellent transparency, less odor, and excellent balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0190] Sample preparation: 1 mg / mL sample solution was prepared using o-dichlorobenzene (containing 0.5 mg / mL of BHT), and the sample was dissolved at 140° C. for about 1 hour.

[0191] By plotting the elution ratio against the molecular weight measured by GPC, the amount of components with a molecular weight of 5000 or less can be determined.

[0192] (8) Intrinsic viscosity [η]cxs

[0193] In the propylene-ethylene block copolymer (A), stickiness and extravasation are particularly problematic because of components soluble in xylene at room temperature (CXS components), so the intrinsic viscosity [η] (dl / g ) is preferably measured on the CXS component.

[0194] Here, CXS is obtained as follows. The propylene-ethylene block copolymer was dissolved in p-xylene at 130°C to form a solution, and then left to stand at 25°C for 12 hours. The precipitated polymer was removed by filtration, and p-xylene was distilled off from the filtrate to obtain the CXS fraction. The intrinsic ...

Embodiment

[0410] Next, in order to more specifically and clearly describe the present invention, the present invention will be described in comparison of Examples and Comparative Examples, and the rationality and effectiveness of the constituent elements of the present invention will be proved in practice.

[0411] In addition, the evaluation methods and resins used in Examples and Comparative Examples are as follows.

[0412] [Measuring methods of various physical properties of propylene-ethylene block copolymer (A)]

[0413] 1) Melt flow rate (MFR)

[0414] According to the method condition M of JIS K7210A, the melt flow rate was tested under the following conditions.

[0415] Test temperature: 230°C

[0416] Rated weight: 2.16kg

[0417] Die shape: diameter 2.095mm length 8.00mm

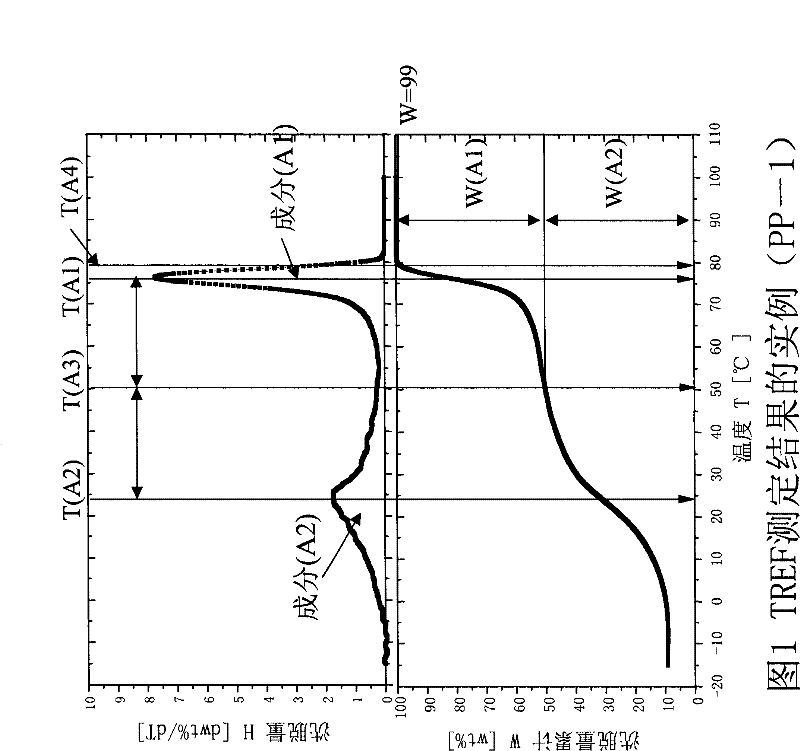

[0418] 2) TREF

[0419] The sample was dissolved in o-dichlorobenzene (containing 0.5 mg / mL of BHT) at 140° C. to prepare a solution. The solution was introduced into the TREF column at 140°C, then co...

manufacture example PP-1A

[0474] [Polymerization Production Example A-1]

[0475] Preparation of prepolymerized catalyst

[0476] (chemical treatment of silicates)

[0477] Add 3.75 liters of distilled water into a 10-liter glass separatory flask equipped with a stirring paddle, and then slowly add 2.5 kg of concentrated sulfuric acid (96%). 1 kg of montmorillonite (Benclay SL manufactured by Mizusawa Chemical Co., Ltd., average particle size = 25 μm, particle size distribution = 10 μm to 60 μm) was further dispersed therein at 50° C., then the temperature was raised to 90° C., and maintained at this temperature for 6.5 hours. After cooling to 50°C, the slurry was filtered under reduced pressure to recover the filter cake. 7 liters of distilled water were added to the filter cake to reslurry and then filtered. This washing procedure was repeated until the pH of the washing liquid (filtrate) exceeded 3.5. The filter cake thus recovered was dried at 110° C. overnight in a nitrogen atmosphere. The weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com