Antistatic wall cloth and production process thereof

A production process and anti-static technology, which is applied in construction, building structure, covering/lining, etc., can solve the problem of single function of anti-static wall cloth, and achieve the effect of excellent cold resistance, good processing performance and air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

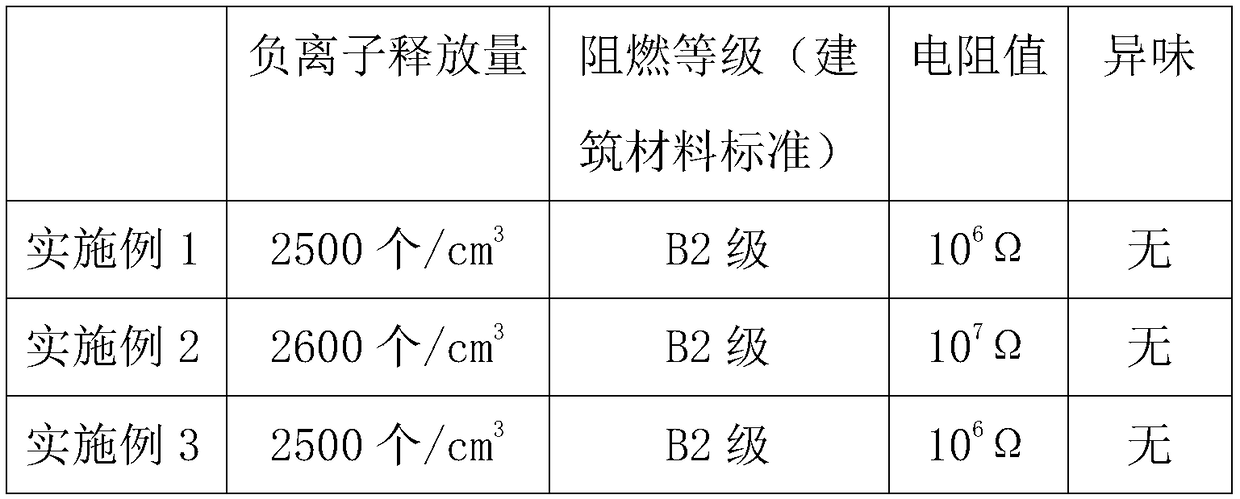

Examples

Embodiment 1

[0039] (1) Bottom preparation

[0040] A. Put 100 parts of polyvinyl chloride resin into a high-speed mixer for stirring, and gradually increase the temperature. When the temperature rises to 60°C, add 35 parts of dioctyl terephthalate and continue stirring. When the temperature rises to At 105°C, add 30 parts of tourmaline powder, 50 parts of conductive carbon black, 3.2 parts of powdered barium zinc, 8 parts of antimony trioxide, 6 parts of methacrylate, and 1 part of oxidized polyethylene wax, and stir for 30 seconds to obtain a mixed material ;

[0041] B, put the mixed material prepared in step A and 20 parts of 4A molecular sieves into the internal mixer, carry out banburying for 6min, and obtain the block mixed material;

[0042] C. Use a two-roll mill to further knead and plasticize the block mixture prepared in step B. The temperature of the two-roll mill is 155° C., and the roll distance is 0.4 cm to obtain a plasticized block mixture;

[0043] D. Use a filter to f...

Embodiment 2

[0054] (1) Bottom preparation

[0055] A. Put 100 parts of polyvinyl chloride resin into a high-speed mixer for stirring, and gradually increase the temperature. When the temperature rises to 60°C, add 35 parts of dioctyl terephthalate and continue stirring. When the temperature rises to At 110°C, add 30 parts of tourmaline powder, 50 parts of conductive carbon black, 3.2 parts of powdered barium zinc, 8 parts of antimony trioxide, 6 parts of methacrylate, and 1 part of oxidized polyethylene wax, and stir for 45 seconds to obtain a mixed material ;

[0056] B, put the mixed material prepared in step A and 20 parts of 4A molecular sieves into the internal mixer, carry out banburying for 6min, and obtain the block mixed material;

[0057] C. Use a two-roll mill to further knead and plasticize the block mixture prepared in step B. The temperature of the two-roll mill is 155° C., and the roll distance is 0.4 cm to obtain a plasticized block mixture;

[0058] D. Use a filter to f...

Embodiment 3

[0069] (1) Bottom preparation

[0070] A. Put 100 parts of polyvinyl chloride resin into a high-speed mixer for stirring, and gradually increase the temperature. When the temperature rises to 60°C, add 35 parts of dioctyl terephthalate and continue stirring. When the temperature rises to At 115°C, add 30 parts of tourmaline powder, 50 parts of conductive carbon black, 3.2 parts of powdered barium zinc, 8 parts of antimony trioxide, 6 parts of methacrylate, and 1 part of oxidized polyethylene wax, and stir for 60 seconds to obtain a mixed material ;

[0071] B, put the mixed material prepared in step A and 20 parts of 4A molecular sieves into the internal mixer, carry out banburying for 6min, and obtain the block mixed material;

[0072] C. Use a two-roll mill to further knead and plasticize the block mixture prepared in step B. The temperature of the two-roll mill is 155° C., and the roll distance is 0.4 cm to obtain a plasticized block mixture;

[0073] D. Use a filter to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com