Device for supplying wrapping base materials for preparing Shaomai food

A supply device and substrate technology, applied in food forming, food coating, food science, etc., can solve problems such as easy to decompose and disperse, lose crispy taste, and seaweed sheets can't be peeled off because of mutual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

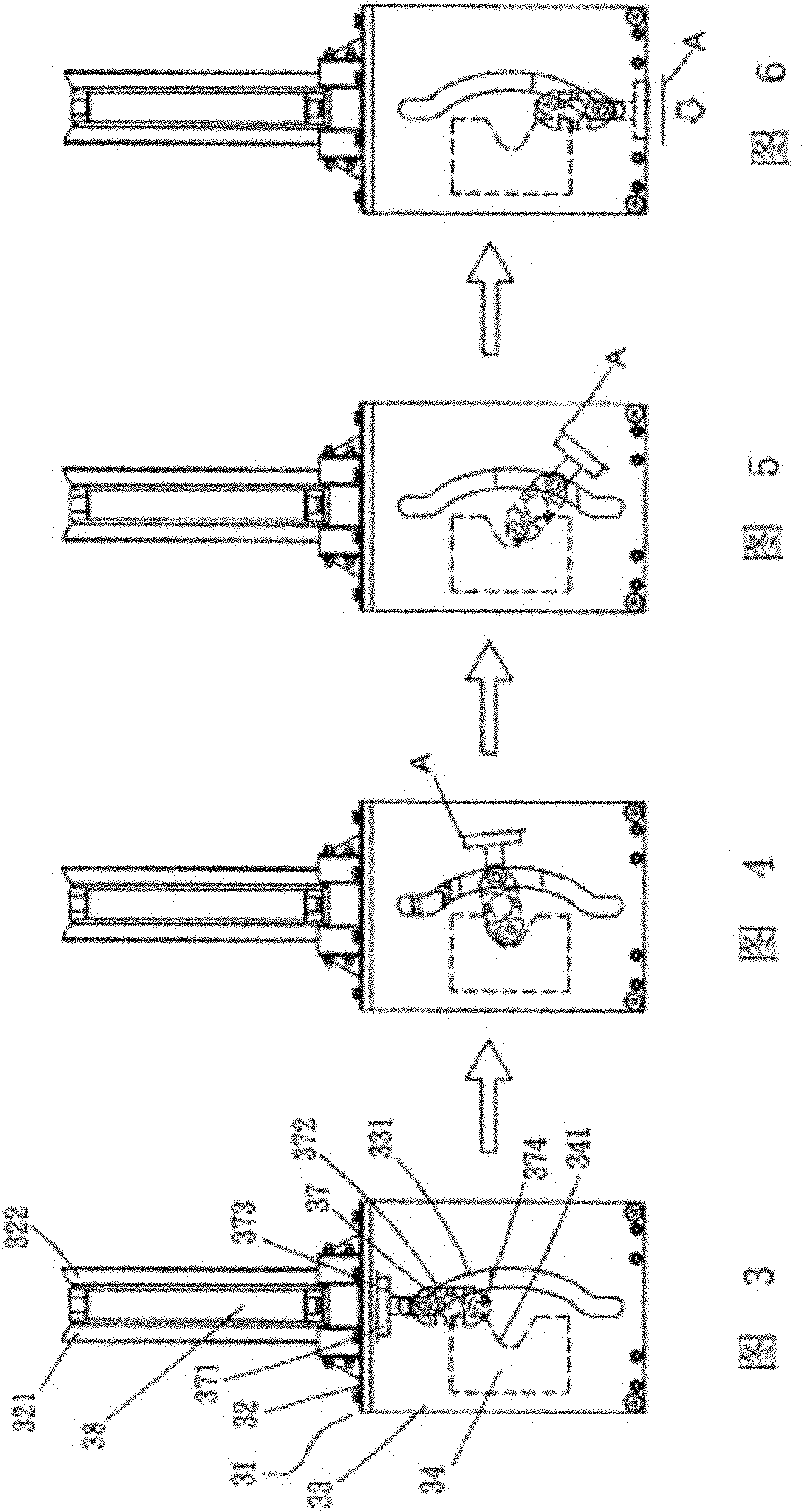

[0028] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

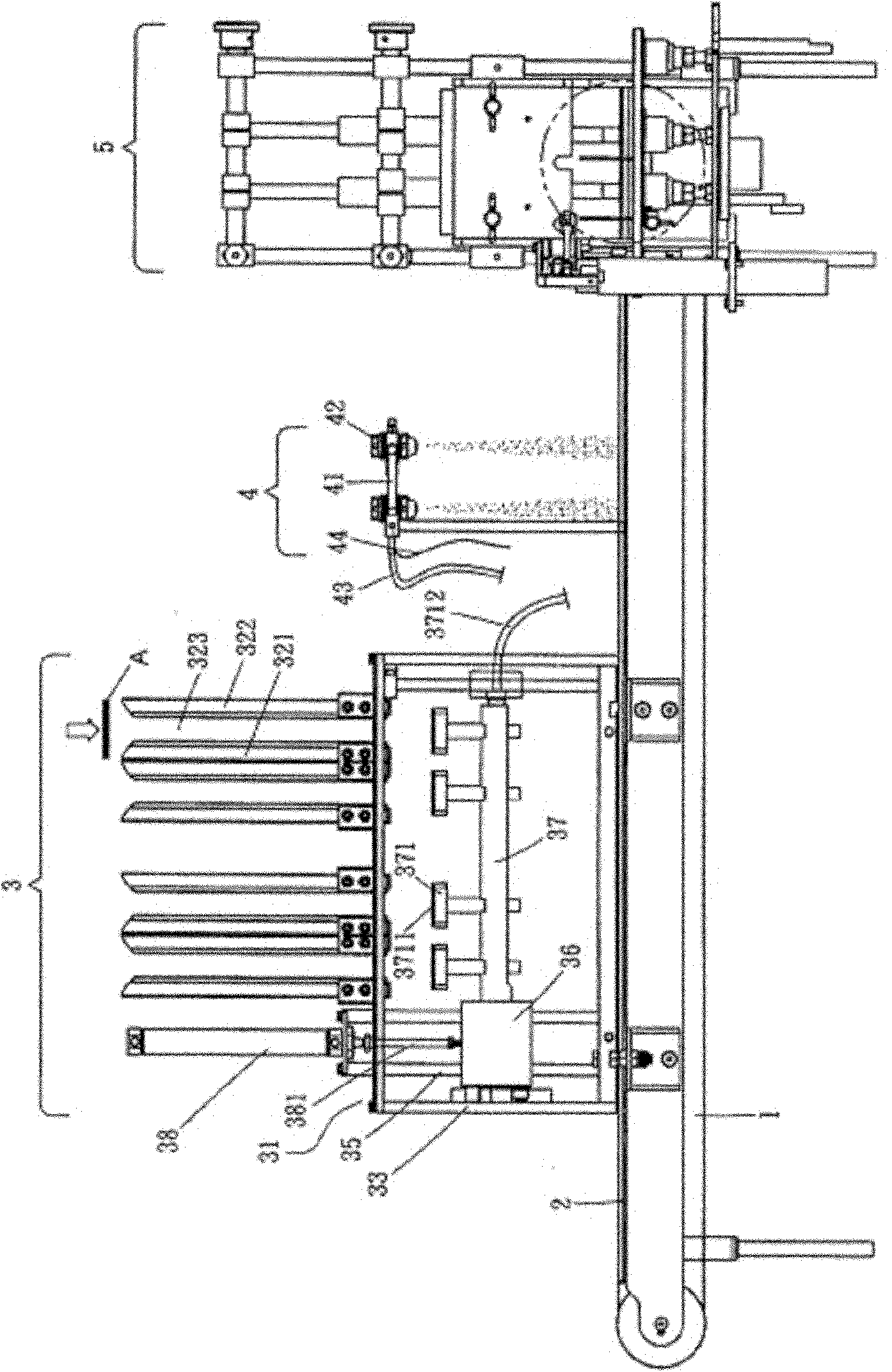

[0029] like figure 1 As shown, the packaging base material supply device for the production of siu mai food of the present invention mainly includes a continuous supply group 3 of siu mai package substrates arranged above the conveyor belt 2 of the machine 1 and located above the conveyor belt 2 of the machine 1 and positioned at the siu mai package The bottom material is continuously supplied to the rear end of the group 3, and the humidifier 4 can be used to spray the shumai wrapping bottom material.

[0030] The so-called shumai wrapping substrate in the present invention is particularly defined as seaweed slices, bean skin slices and spring roll skin slices that are fragile and dry.

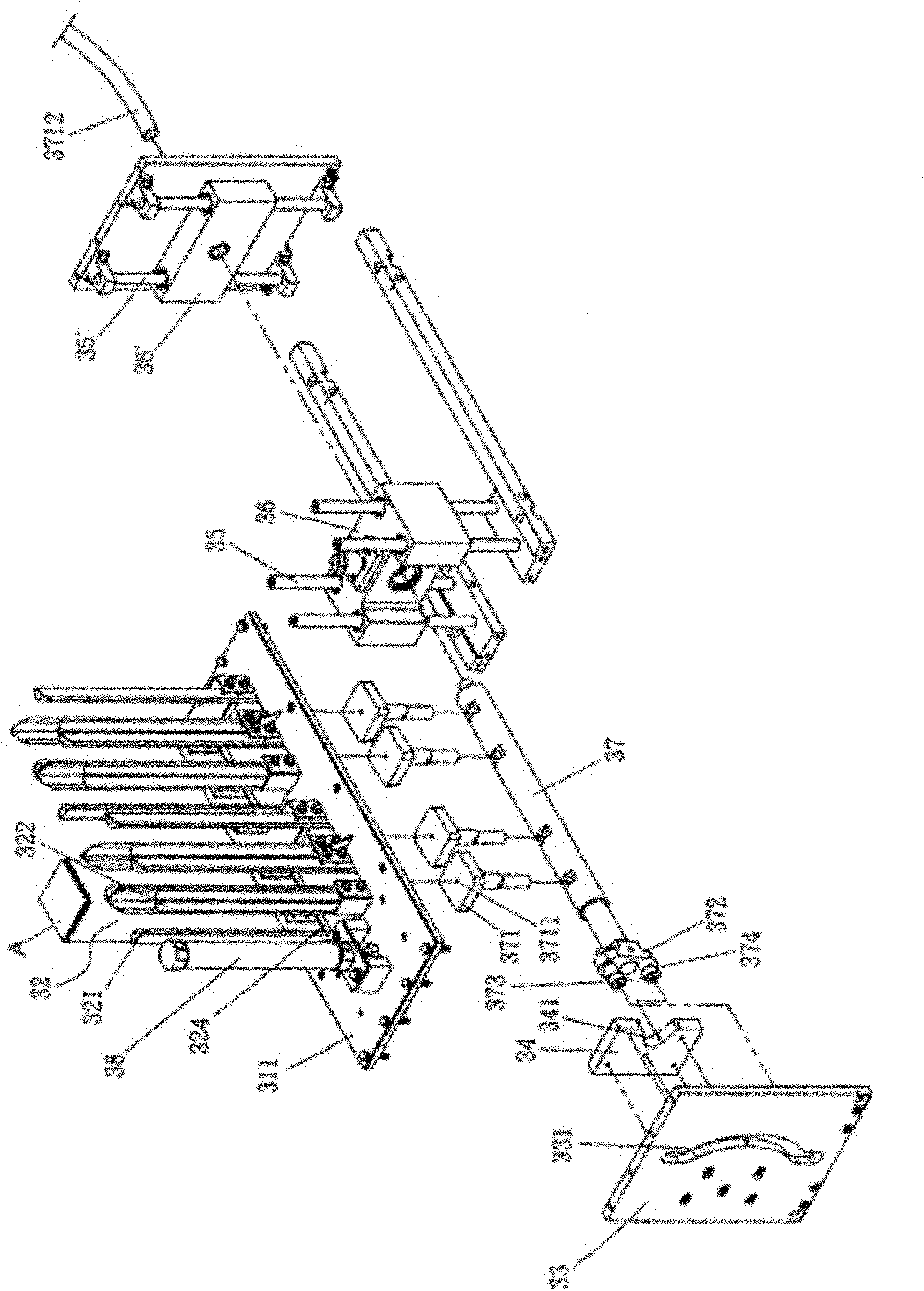

[0031] like figure 2 As shown, the siu mai package base material continuous supply group 3 is provided with a frame body 31, on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com