Waterborne aromatic polyisocyanate cross-linking agent and preparation method thereof

A technology of polyisocyanate and diisocyanate, which is applied in the field of water-based aromatic polyisocyanate crosslinking agent and its preparation, can solve the problems of low activity and poor practical effect, achieve low film forming temperature, facilitate the summary of production experience, and stabilize Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

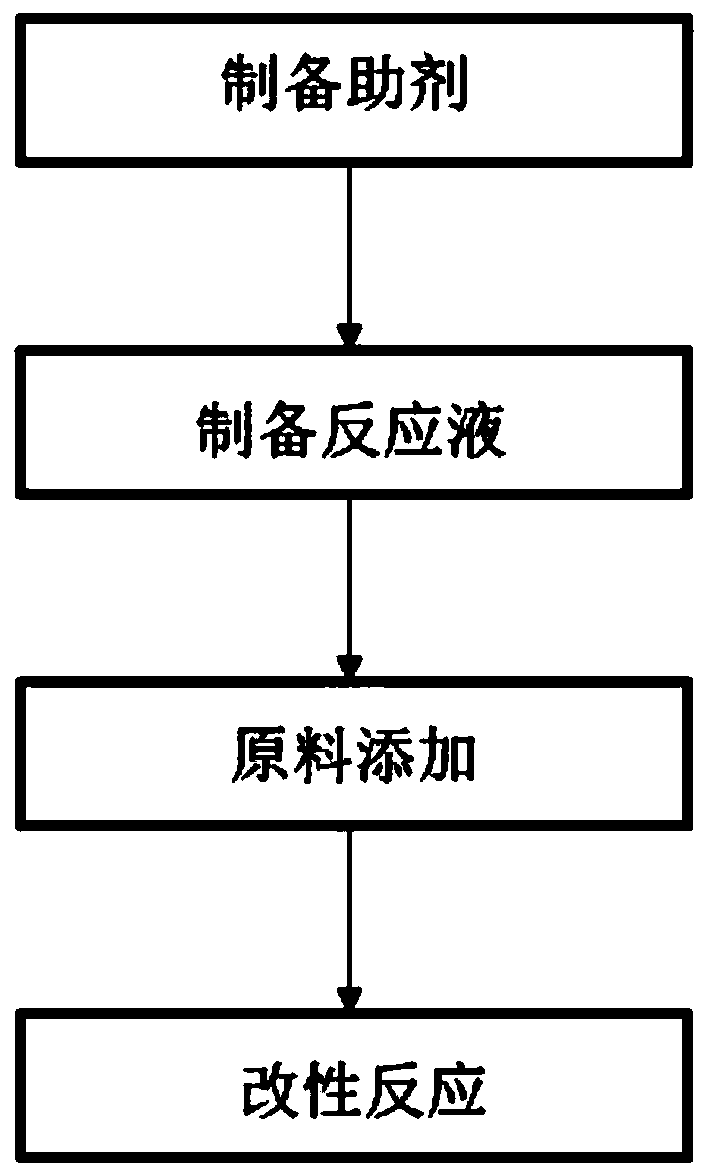

Method used

Image

Examples

Embodiment 1

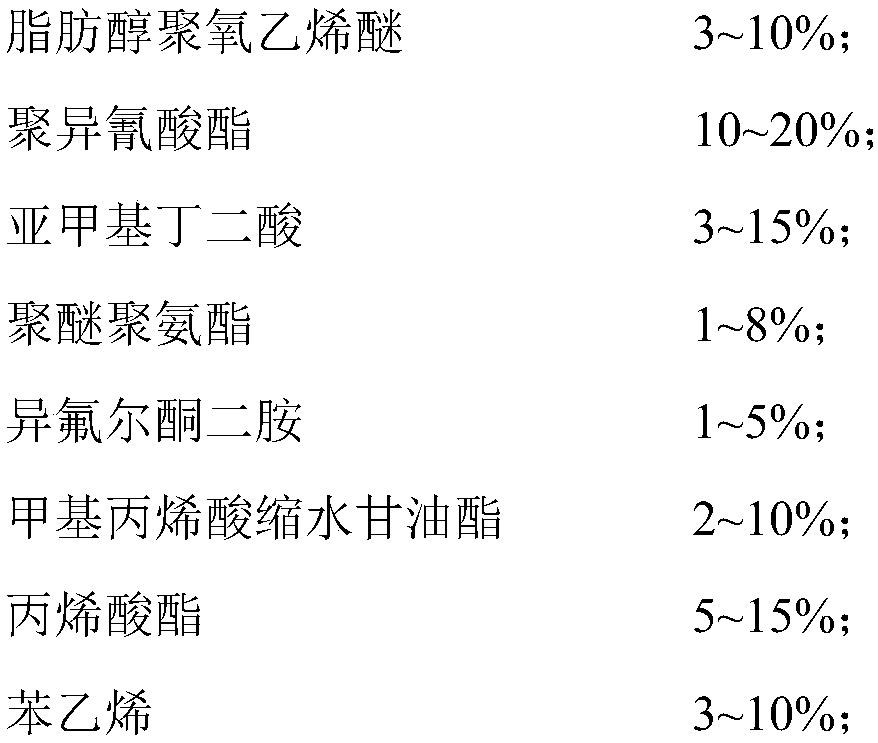

[0032] A water-based aromatic polyisocyanate crosslinking agent, which comprises the following components by mass percentage:

[0033] Fatty alcohol polyoxyethylene ether 3~10%, polyisocyanate 10%, methylenesuccinic acid 3%, polyether polyurethane 8%, isophorone diamine 4%, glycidyl methacrylate 8%, acrylic acid 10% of ester, 5% of styrene, 8% of isopropanol, 3% of auxiliary agent and the balance are deionized water.

[0034] In this embodiment, the polyisocyanate is any one of diisocyanate, isophorone diisocyanate, bicyclic and methane diisocyanate, and tetramethylbenzene dimethylene diisocyanate.

[0035] In this embodiment, the auxiliary agent is composed of the following raw materials by weight, wherein 1% of silane coupling agent, 3% of TAC, 10% of styrene, 20% of phytate, 3% of neopentyl glycol, Antioxidant 1%, diethylene glycol 5%, and the balance ethanol.

[0036] In this embodiment, the antioxidants are polymers of 2-acetone and N-phenylaniline, tris(nonylphenol) ph...

Embodiment 2

[0043] A water-based aromatic polyisocyanate crosslinking agent, which comprises the following components by mass percentage:

[0044] Fatty alcohol polyoxyethylene ether 310% (the percentage here seems wrong, please confirm), polyisocyanate 10%, methylene succinic acid 3%, polyether polyurethane 1%, isophorone diamine 2%, methyl Glycidyl acrylate 5%, acrylate 5%, styrene 10%, auxiliary agent 5% and the balance is deionized water.

[0045] In this embodiment, the polyisocyanate is any one of diisocyanate, isophorone diisocyanate, bicyclic and methane diisocyanate, and tetramethylbenzene dimethylene diisocyanate.

[0046] In this example, the auxiliary agent is composed of the following raw materials by weight, wherein 3% of silane coupling agent, 3% of TAC, 4% of styrene, 35% of phytate, 3% of neopentyl glycol, 3% of anti- Oxidant 5%, diethylene glycol 10%, and the balance ethanol.

[0047] In this embodiment, the antioxidants are polymers of 2-acetone and N-phenylaniline, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com