High wear-resistant and impact-resistant aramid fiber core conveyor belt and its production process

A production process and impact-resistant technology, applied in the field of conveyor belts, can solve the problems of poor compression fatigue resistance of aramid fibers, long transmission lines, multi-layer stacking to improve strength, etc., to achieve good dynamic performance, increased rubber strength, Appropriate effect of belt softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

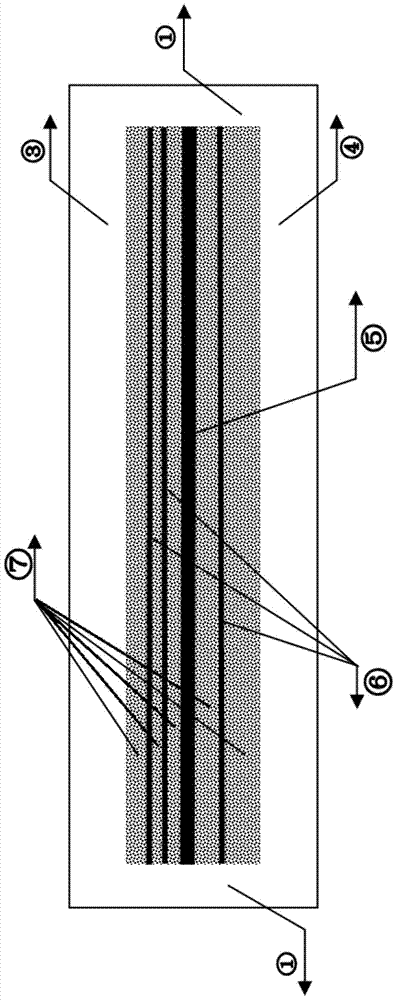

[0028] figure 1 A high wear-resistant and impact-resistant aramid core conveyor belt is shown, which is composed of an aramid canvas skeleton layer 5, an impact-resistant and tear-resistant buffer layer 6, an upper covering rubber layer 3, a lower covering rubber layer 4 and an edge rubber layer 1 The upper side of the aramid canvas skeleton layer 5 is provided with two layers of impact-resistant and tear-resistant buffer layers 6, and the lower side of the aramid canvas skeleton layer 5 is provided with one layer of impact-resistant and tear-resistant buffer layers 6; the aramid canvas skeleton layer 5 Between the impact-resistant and tear-resistant buffer layer 6, between the adjacent impact-resistant and tear-resistant buffer layers 6, between the tear-resistant buffer layer 6 and the upper and lower covering adhesive layers and the edge adhesive layer through adhesive glue (after forming In the structure of the conveyor belt, the adhesive layer 7) is bonded and vulcanized to...

Embodiment 2

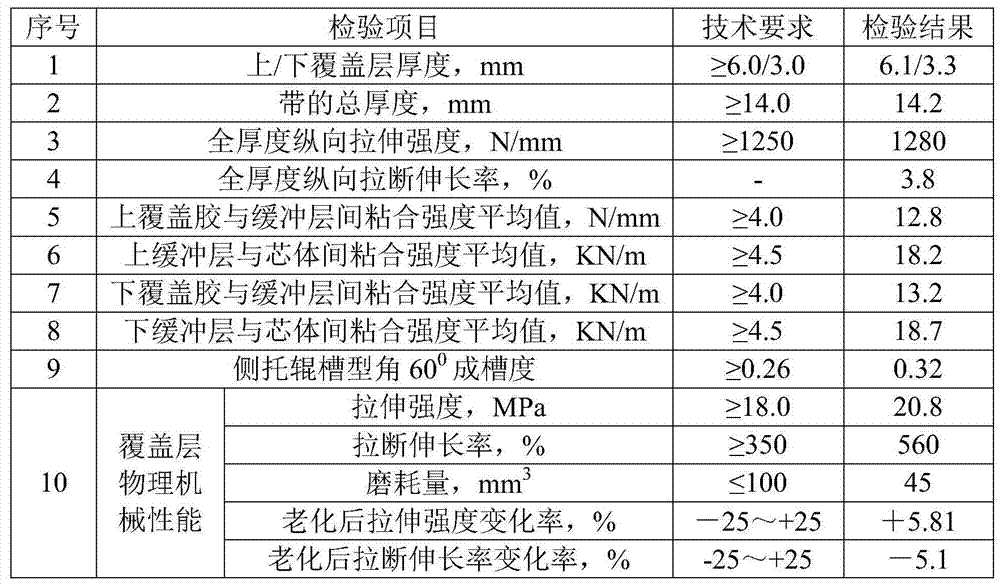

[0030] High wear-resistant and impact-resistant aramid conveyor belt specification 1250N / mm-1000mm (6+3), including diameter straight weft aramid canvas, impact-resistant and tear-resistant buffer layer, adhesive rubber layer, high wear-resistant and impact-resistant covering glue layer. Among them: the diameter straight weft aramid canvas warp aramid 3360dtex×2 Z90×4S70+1880 dtex nylon 66×2 Z60×1S70, that is, the warp direction aramid primary twisted yarn 3360dtex×2, twist (Z) 90, Nylon 66 primary twist yarn 1880 dtex×2, twist (Z) 60, double twist is 4 strands of aramid primary twist strand plus 1 strand of nylon 66 strand, double twist twist (S) 70, density 44 strands / dm. Nylon 66 weft thread 1880 dtex×6Z60, density 32 threads / dm. Nylon 66 connecting wire 2200 dtex×1Z100, density 88 pieces / dm. Aramid canvas thickness 2.8mm, weight per unit area 1.9kg / m 2 .

[0031] A single layer of impact and tear-resistant cushioning is used above and below.

[0032] Adhesive formula,...

Embodiment 3

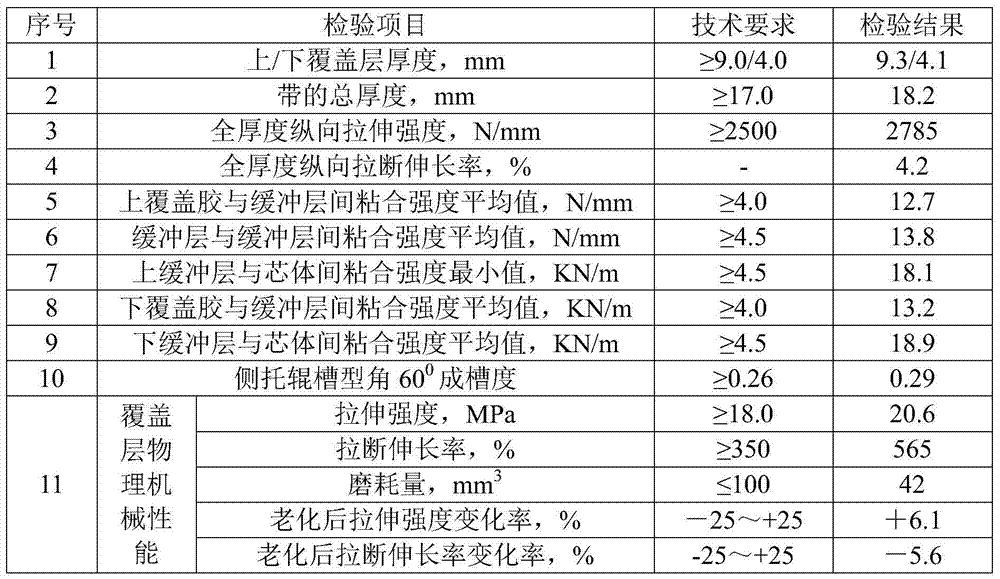

[0049] High wear-resistant and impact-resistant aramid conveyor belt specification 2500N / mm-1400mm (9+4), diameter straight weft aramid canvas warp aramid 3360 dtex×9Z40×3S40+1880 dtex nylon 66×5 Z60×1S40, namely warp direction Aramid primary twisted yarn 3360dtex×9, twist (Z) 40, nylon 66 primary twisted yarn 1880dtex×5, twist (Z) 60, double twist is 3 strands of aramid primary twisted yarn plus 1 strand of nylon 66 strands, Double twist twist (S) 40, density 22 strands / dm. Weft thread 1880dtex nylon 66×9Z60, density 32 threads / dm. The connecting wire is 3300dtex nylon 66×1Z100, and the density is 44 pieces / dm. Aramid canvas thickness 3.2mm, weight per unit area 1.94.6kg / m 2 , on the rubber side of the upper cover, use a second layer of shock-resistant buffer layer, which is placed staggered with the center line of the belt at an angle of 45 degrees. A single layer of shock-resistant buffer layer is used on the rubber side of the lower cover, and it is placed vertically wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com