Device and method for plastic formation of micro parts through manual submerging type cavitation jetting

A plastic forming and submersion technology, which is applied in the direction of abrasive feeding device, used abrasive processing device, explosion generating device, etc., can solve the problem of high positioning and movement accuracy of punch press, limited jet strength, low processing efficiency, etc. problem, achieve the effect of reducing cost input, improving service life and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

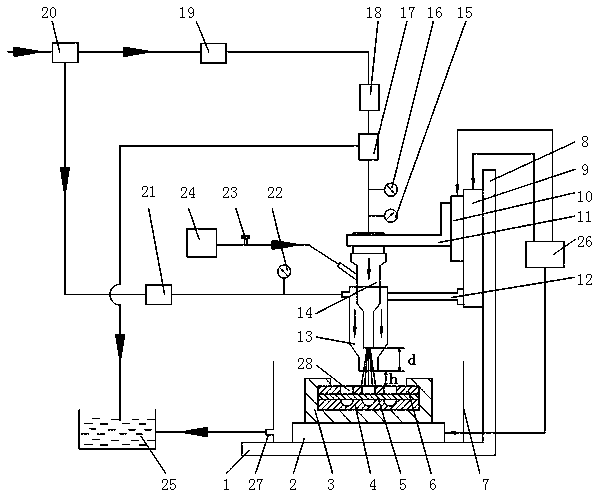

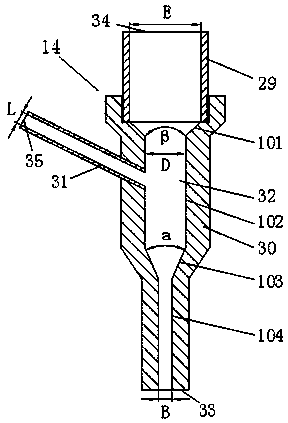

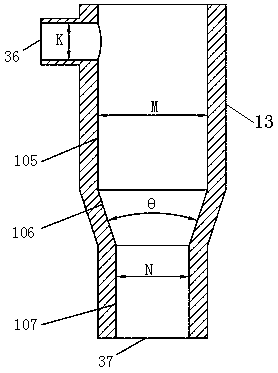

[0028] An artificial submerged cavitation jet micro-part plastic forming device of the present invention includes a horizontal workbench base 1 and a vertical workbench base 8, the horizontal workbench base 1 and the vertical workbench base 8 are mutually perpendicular and fixed connected. The container 7 is fixedly placed on the upper surface of the horizontal workbench base 1, and the container 7 is placed horizontally. A horizontally movable workbench 2 is installed in the container 7, and a connecting fixture 3 is fixed on the upper surface of the horizontally movable workbench 2. The upper part of the fixture 3 is open, and the inside is stacked with the die 4, the micro parts 5 to be processed and the mask 6 sequentially from bottom to top, and the die 4, the micro parts 5 to be processed and the mask 6 are all clamped by the fixture 3 , the mask 6 is provided with a shaped through hole 28 . Above the forming through hole 28 of the mask 6 is a casing 13, the casing 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com