Vehicle body structure

A body and structure technology, applied in the field of lower body structure, can solve the problems of inability to pass and join the inner parts of the center pillar, and achieve the effects of ensuring rigidity and strength, improving rigidity and strength, and improving productivity and yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

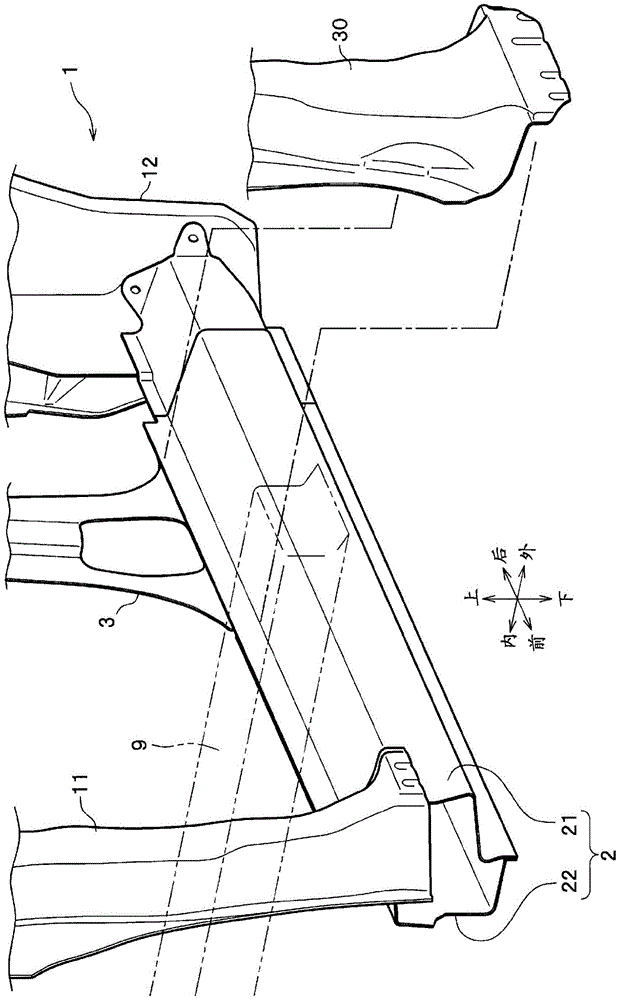

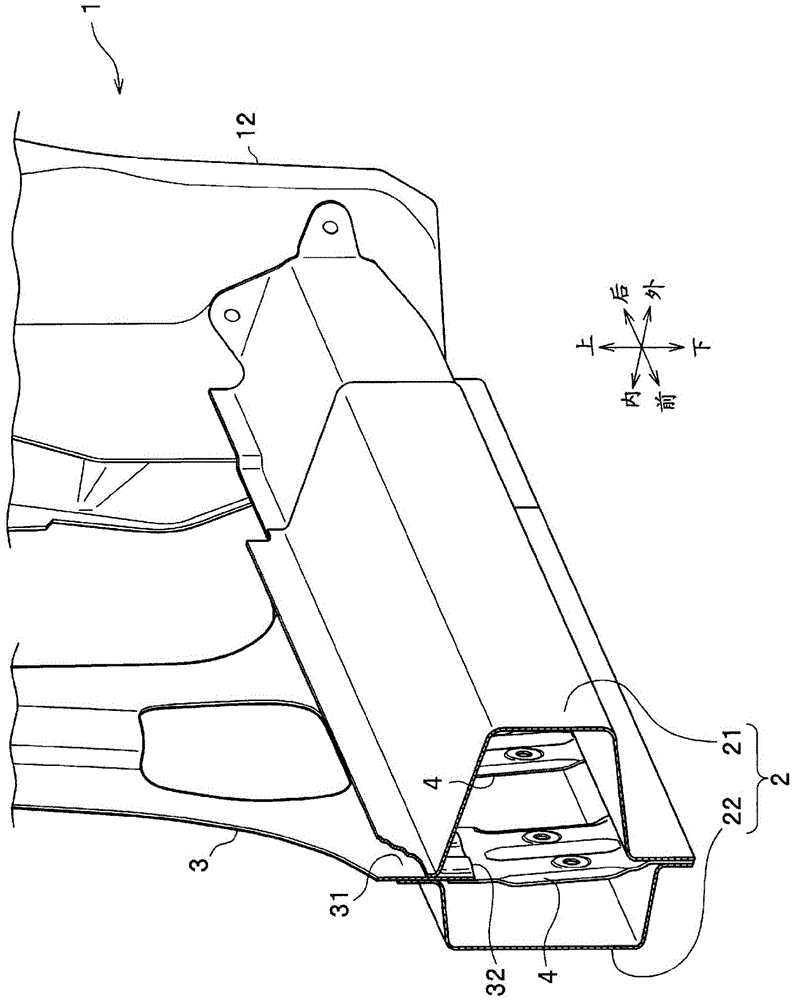

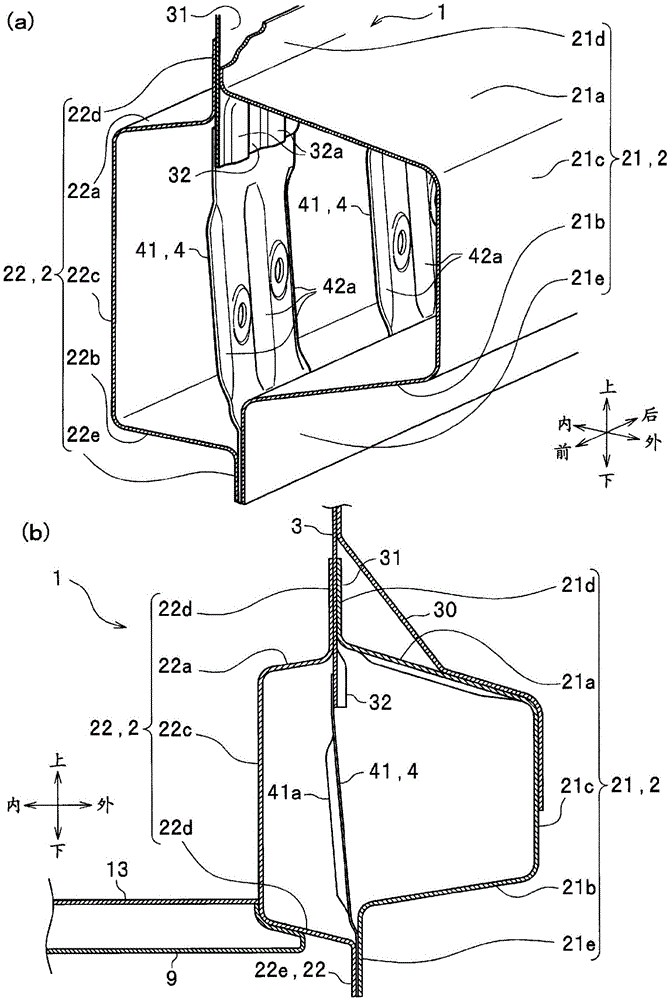

[0052] properly refer to Figure 1 to Figure 5 A vehicle body structure 1 of a vehicle (not shown) according to the first embodiment of the present invention will be described in detail. In addition, the type of vehicle is not particularly limited. For convenience of description, the direction of the vehicle is referred to as the front-rear direction, the up-down direction, and the vehicle width direction (left-right direction). .

[0053] figure 1 It is a perspective view of the left side of the vehicle body viewed from the front outer side, and shows the structure of the vehicle body from the front pillar 11 to the rear wheel house 12 .

[0054] Such as figure 1 As shown, the vehicle body structure 1 according to the first embodiment of the present invention includes: a side sill 2 extending in the front-rear direction on the side of the vehicle body; Square extension column; extension 4 (refer to figure 2 ) that is joined to the lower end of the center pillar inner me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com