Reel-to-reel MOCVD equipment capable of performing continuous XRD on-line monitoring

A roll-to-roll and equipment technology, which is applied in the direction of material analysis using radiation diffraction, can solve problems such as wasting time, wasting materials, and wasting processes, and achieve the effect of improving economic benefits, improving yield and production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

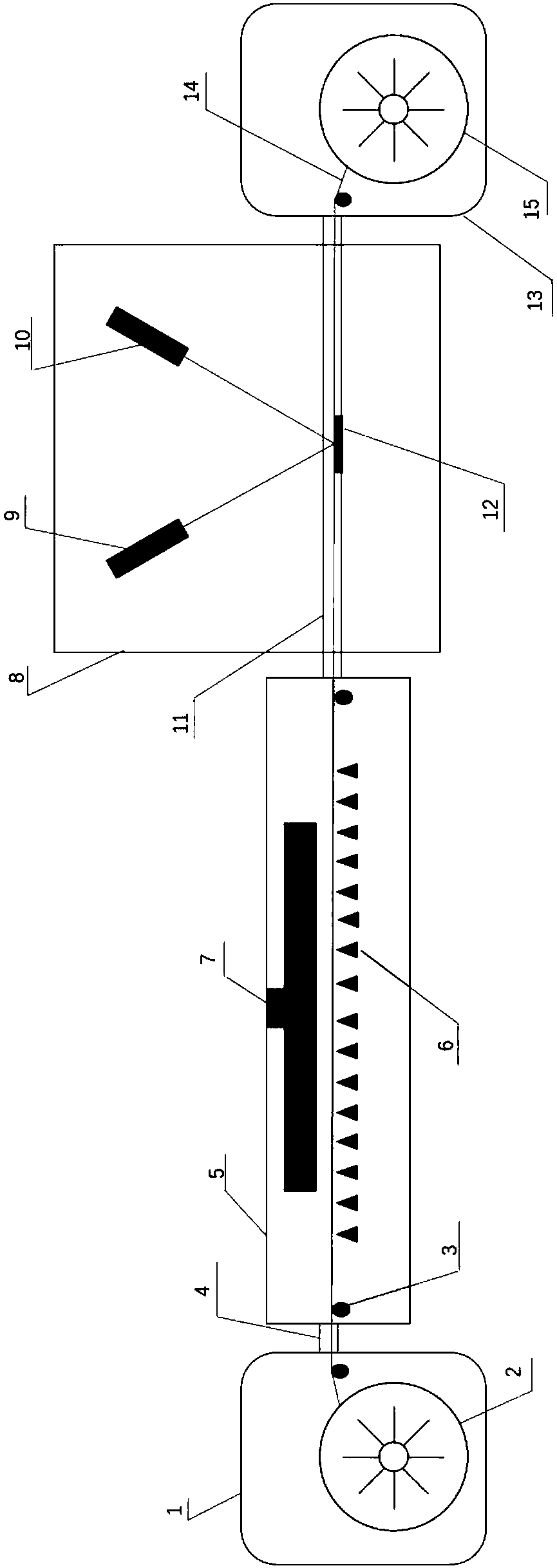

[0025] The stainless steel strip coated with the buffer layer is wound on the unwinding pulley 2 and the take-up pulley 15, and fixed in the unwinding chamber 1 and the take-up chamber 13 respectively.

[0026] The drive motor controls the take-up pulley, adjusts the tape speed (1mm / s-100mm / s), step length (1mm-5m), and pulls the tape into the reaction chamber slowly. After the tape is deposited in the heating zone, it leaves the reaction chamber and enters the quartz inside the tube.

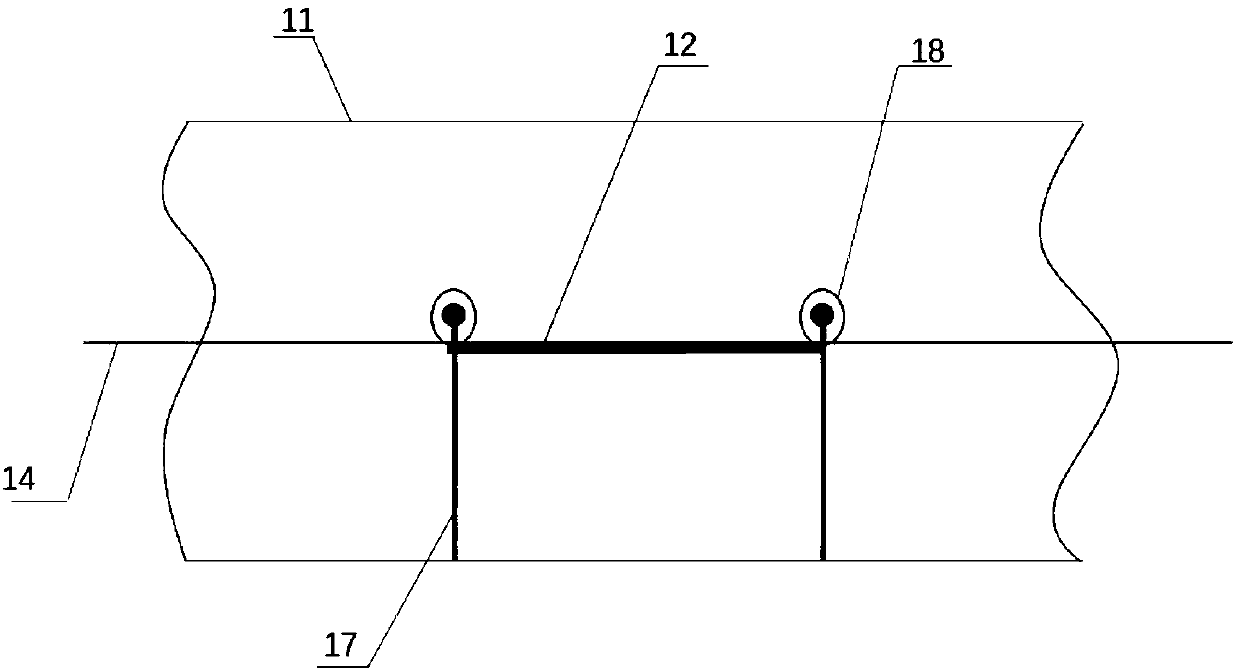

[0027] When the stainless steel strip passes through the sample stage 12, the pressing wheels 18 at both ends will press the strip on the sample stage to prevent it from vibrating.

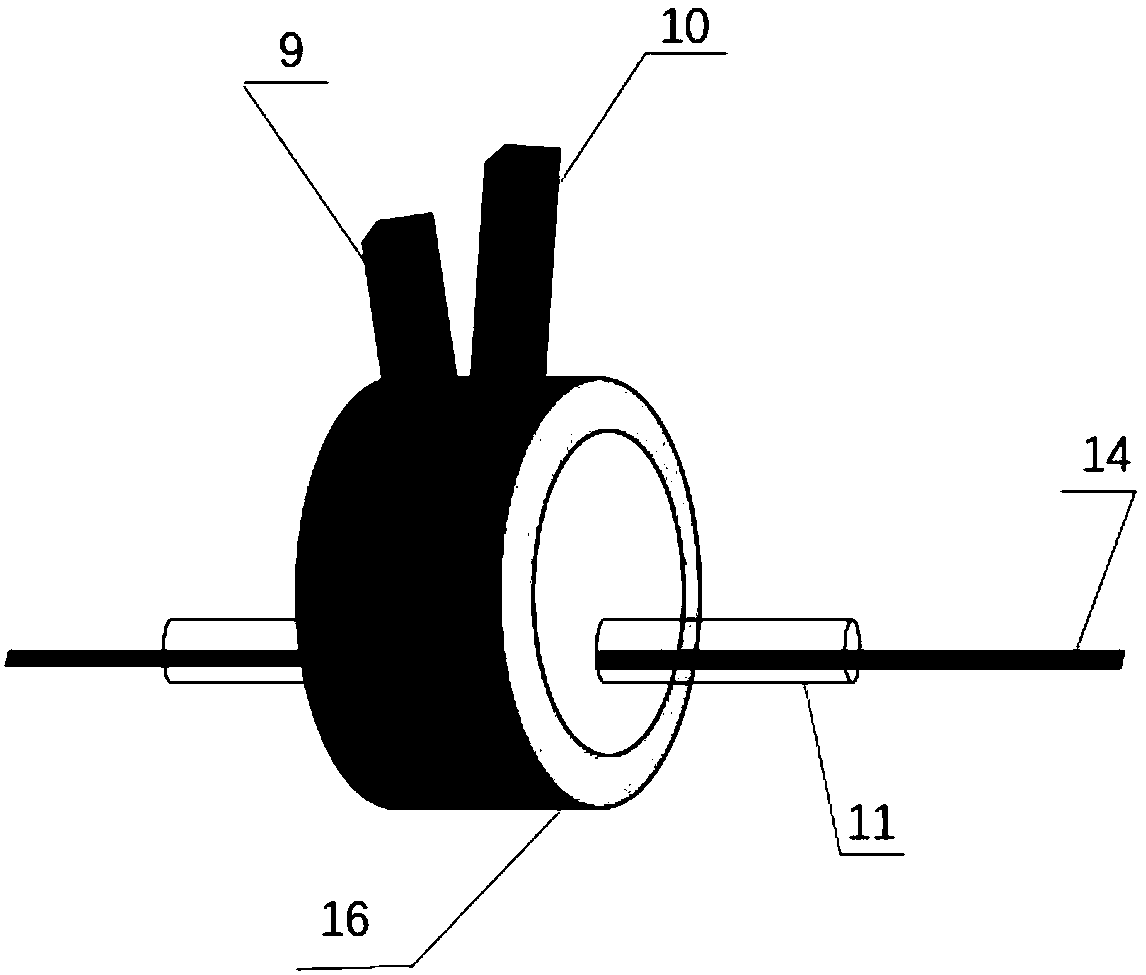

[0028] The XRD detection system uses 2θ scanning to measure the diffraction peak of the strip (005). The sampling method is continuous sampling. Analysis and cell parameter meter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com