Compound material object and fabrication method thereof

A manufacturing method and composite material technology, applied in the direction of electrical components, electrical equipment shells/cabinets/drawers, etc., can solve the problems of high material and labor costs, low strength and reliability, and high cost, and achieve the process of reducing consumption and combining Simplified, thin body wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

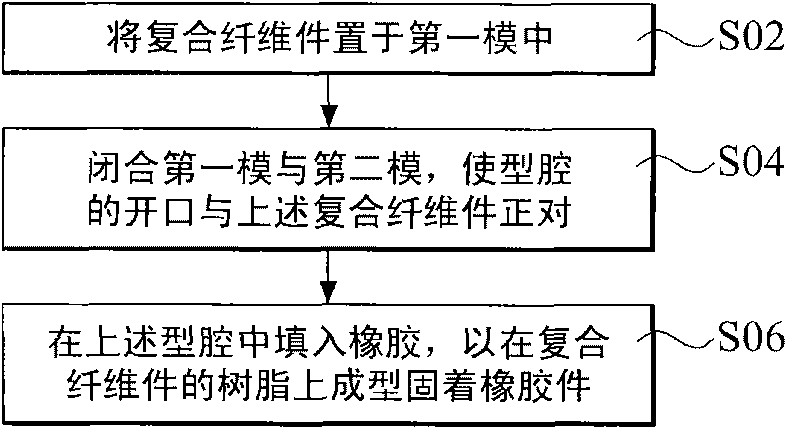

Method used

Image

Examples

Embodiment Construction

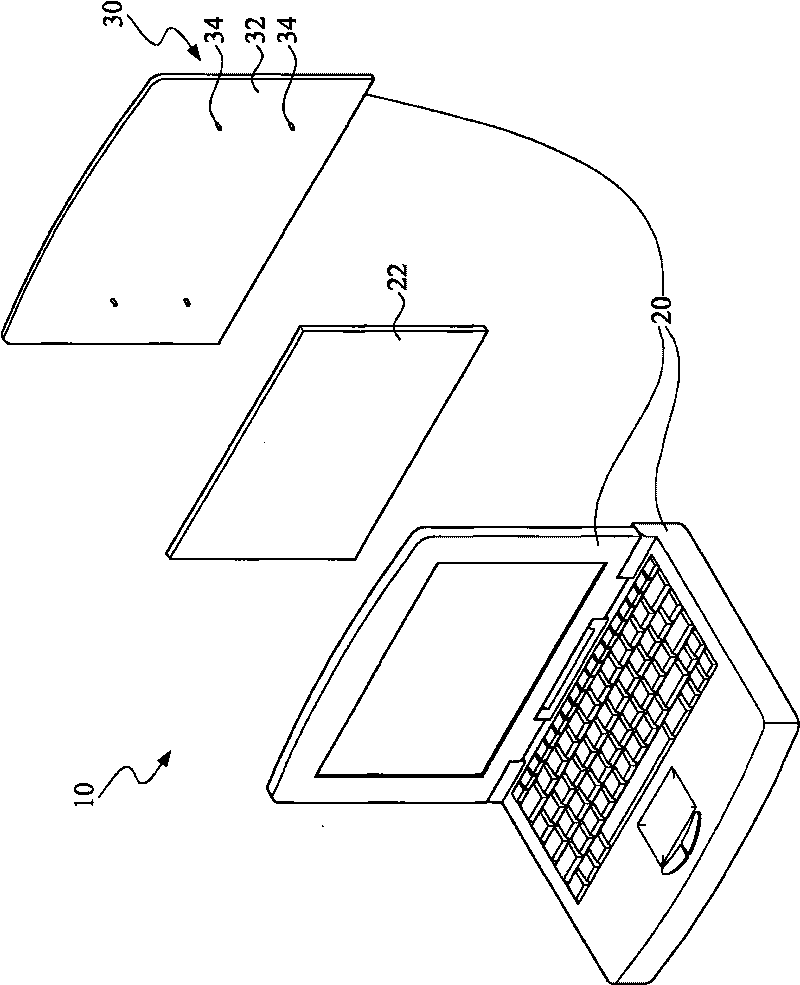

[0021] see figure 1 , figure 1 It is an exploded schematic diagram of part of the structure of the notebook computer 10 . To illustrate with a preferred embodiment, the composite material object 30 manufactured by the present invention can be applied to the purpose of the shell 20 required for commodities, such as electronic commodities such as notebook computers 10, liquid crystal displays, smart mobile phones, etc., or It is a non-electronic commodity such as a packaging box, furniture, etc. The composite material object 30 is suitable as the main body of the shell member 20 .

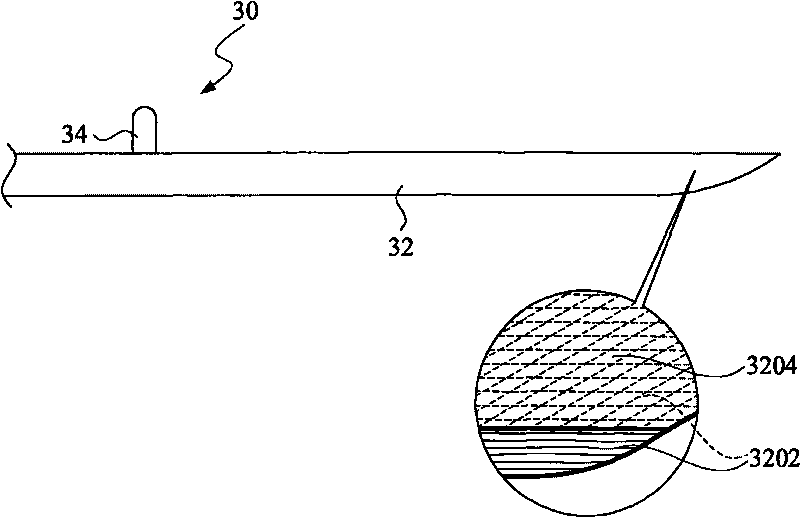

[0022] In the figure, the use of the composite material object 30 is described by taking the upper cover of the notebook computer 10 having the liquid crystal panel 22 as an example. The composite material object 30 includes an integrally formed composite fiber piece 32 and a rubber piece 34. The side of the composite fiber piece 32 opposite to the rubber piece 34 is suitable for use as the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com