Axle shaft steel and preparation method thereof

A technology of axle steel and molten steel, applied in the direction of metal rolling, etc., can solve the problems of increased production cost, unrealizable plasticity and toughness, limited strength and toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

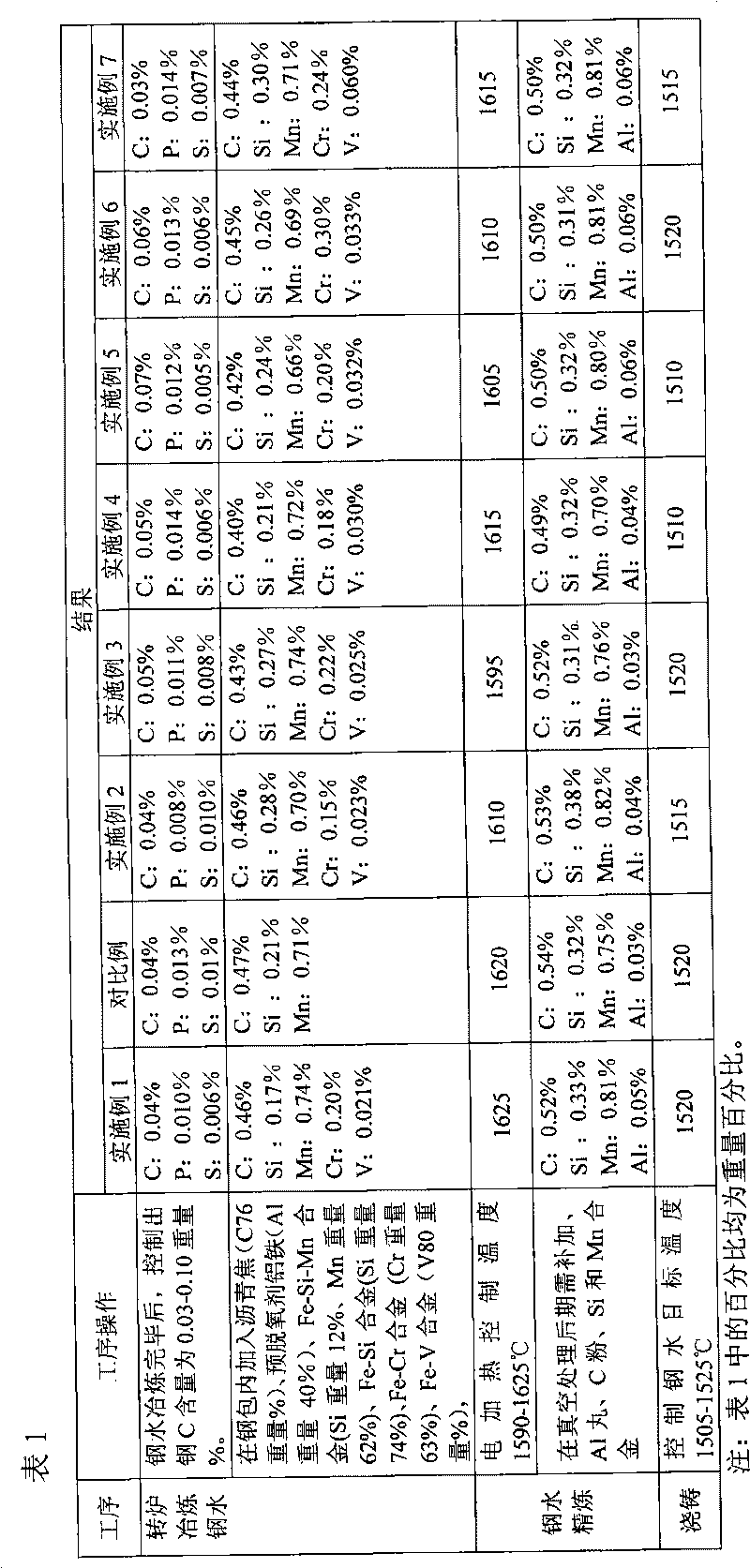

[0012] The present invention also provides a method for preparing axle steel, wherein the method includes smelting molten steel and refining outside the furnace, the smelting molten steel sequentially includes a blowing step and an alloying step, in which the carbonaceous material is sequentially , deoxidizer, ferrosilicon alloy, silicon manganese alloy, ferrochrome alloy and ferrovanadium alloy are added to molten iron, and make the molten steel obtained in this step: based on the total weight of molten steel, C0.40-0.47% by weight, Si 0.17 -0.3% by weight, Mn 0.65-0.75% by weight, V 0.02-0.06% by weight, Cr 0.15-0.3% by weight; the refining outside the furnace is carried out under vacuum conditions, the refining temperature is 1590-1625°C, and the refining time is 12-15 minutes, wherein, one or more of carbonaceous materials, iron-silicon alloys and iron-manganese-silicon alloys and aluminum are added during the refining outside the furnace, so that the molten steel obtained ...

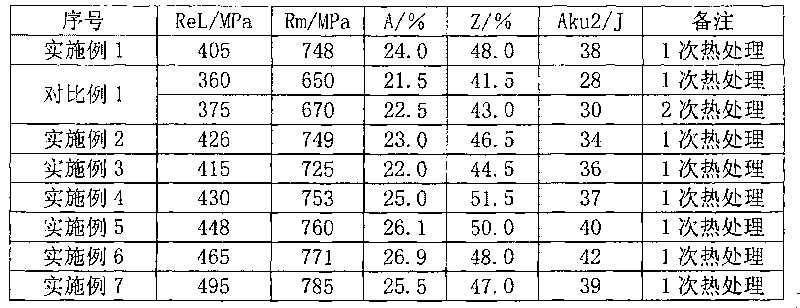

Embodiment 1-7

[0021] These examples illustrate the axle steels provided by the present invention.

[0022] (1) Smelting molten steel:

[0023] Desulfurized and dephosphorized hot metal is used to smelt the axle steel. When the C content in the molten steel is 0.03%-0.10% (the specific values controlled by each embodiment are shown in Table 1), the steel is immediately tapped into the ladle. When tapping the steel, first add pitch coke (Panzhihua Yangcheng Metallurgical Accessories Co., Ltd.) or anthracite (Panzhihua Yangcheng Metallurgical Accessories Co., Ltd.) Material Co., Ltd.) 3 kg / ton, control the oxygen concentration in molten steel to 100×10 -6 Below, after adding aluminum and iron, add Fe-Si-Mn (Anyang Hengwang Metallurgical Refractory Co., Ltd.), Fe-Si (Anyang Hengwang Metallurgical Refractory Co., Ltd.), Fe-Cr (Panzhihua Panhong Metallurgical Products Co., Ltd.), Fe-V (Panzhihua Panhong Metallurgical Products Co., Ltd.), carry out alloying of Si, Mn, Cr, V elements, control t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com