Manufacturing method and special forming mold for synthetic sole timber

A technology for forming molds and skids, which is applied to other household appliances, household appliances, wood processing appliances, etc., can solve the problems of high labor intensity for workers, large volume of large pallets, and low production efficiency, so as to reduce manpower input, The effect of labor cost reduction and production efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

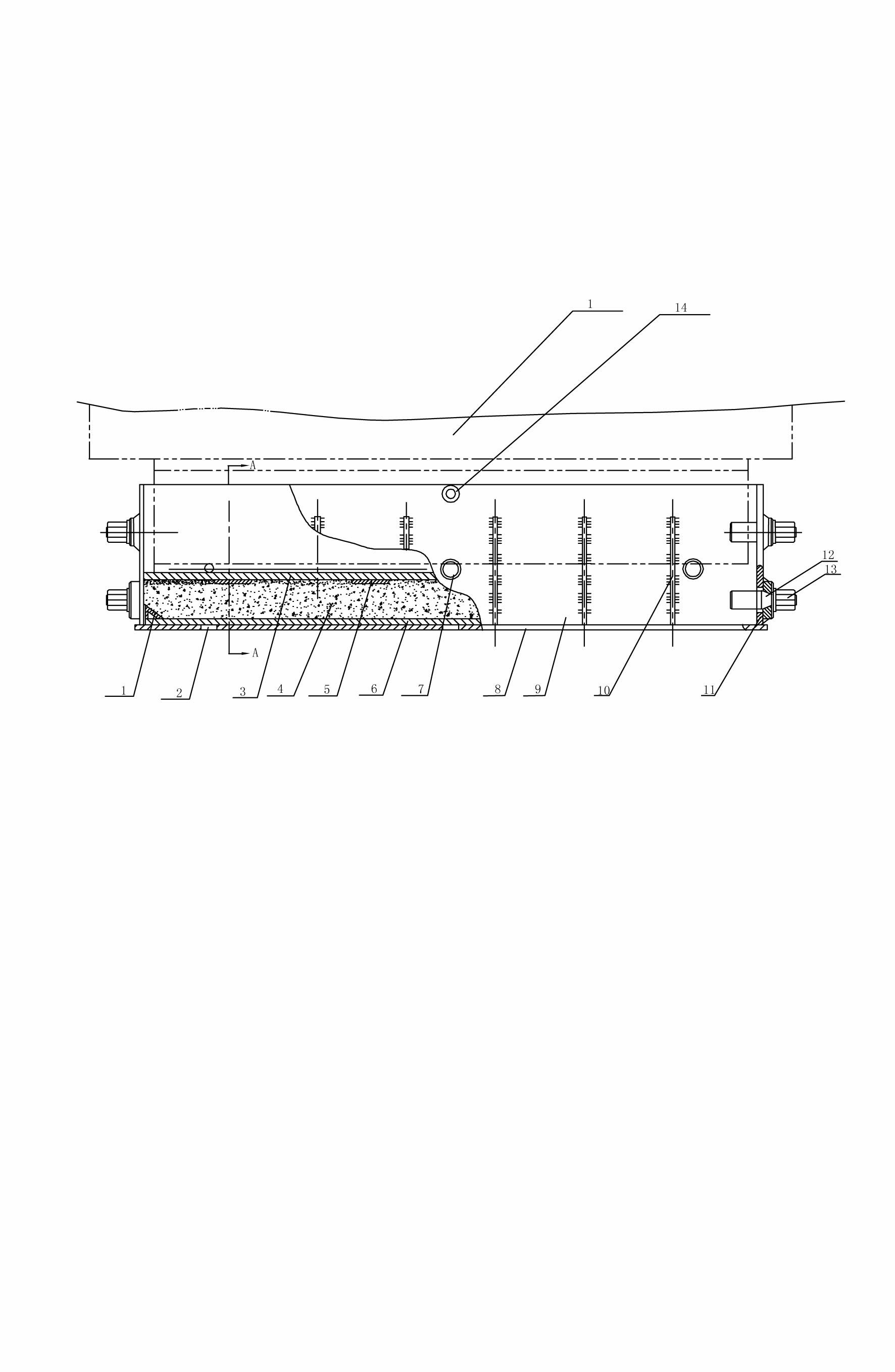

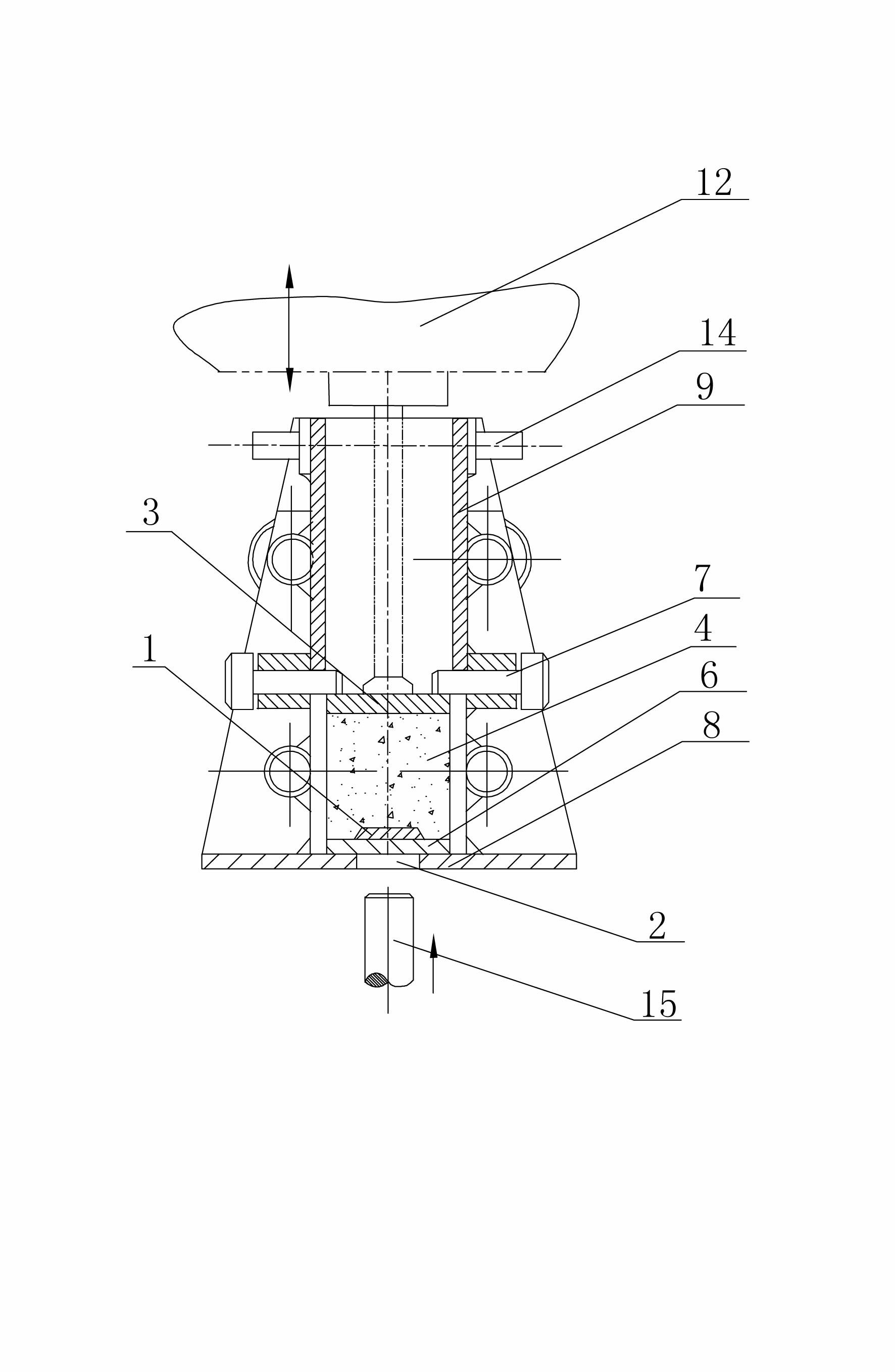

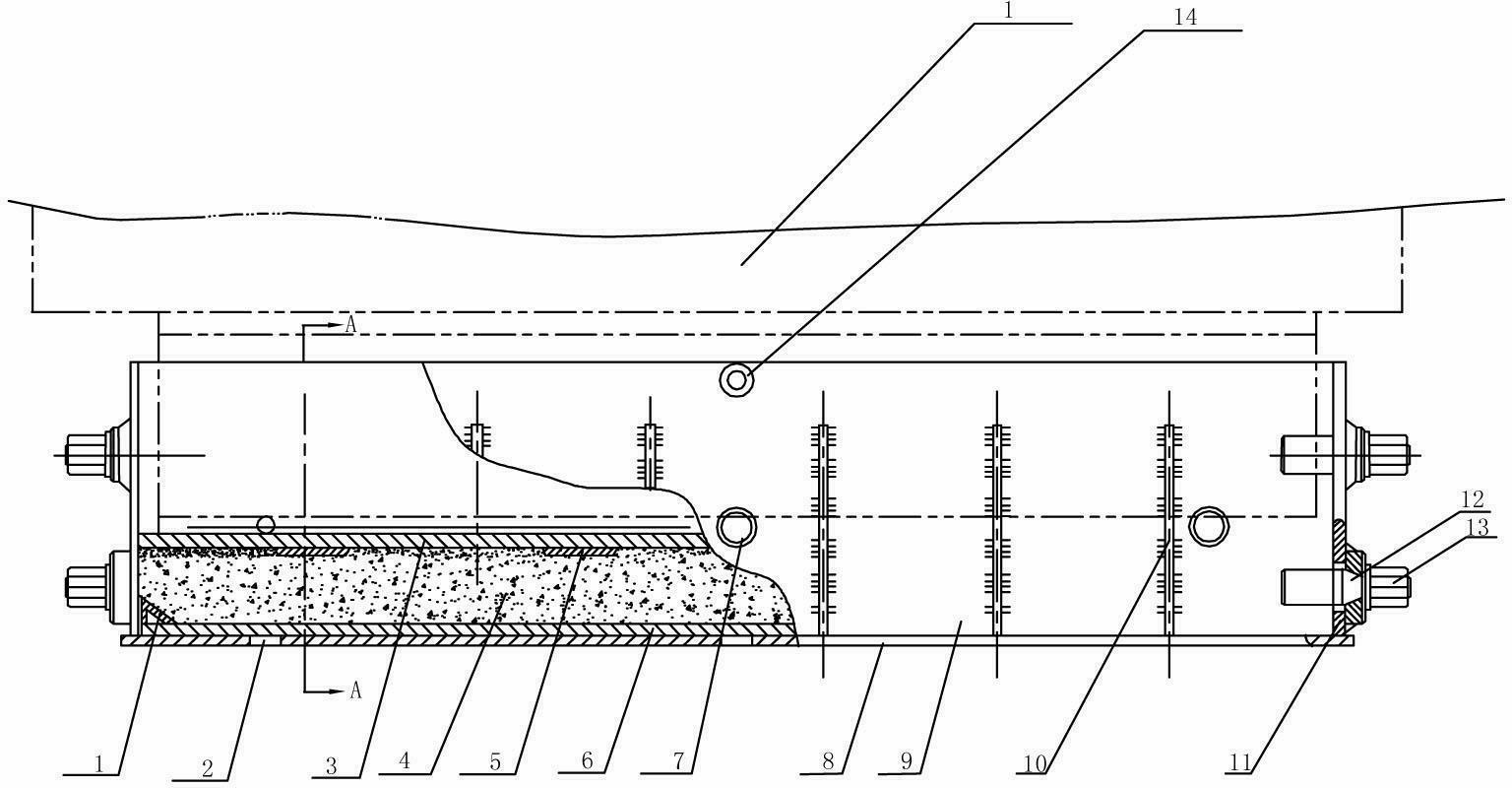

[0016] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] According to the purpose of the present invention of the present invention is achieved like this:

[0018] According to the production method of synthetic dunnage of the present invention, it is characterized in that the technical process is: one or more powders or flakes of artificial wood shavings, sawdust, straw, and wheat straw—dry—add binder and stir Preparation of synthetic skid raw materials—raw materials into the mold extrusion—compression molding—heating—demolding molding, specifically includes the following steps:

[0019] 1) Assemble the mold, lay a layer of prepared synthetic skid powder raw material on the bottom of the die plate, then alternately add reinforcement layers and synthetic skid sheet material layers respectively, and lay a layer of synthetic skid on the top The powder raw material layer, after fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com