Vacuum box system for laser processing

A technology of laser processing and vacuum box, applied in the field of vacuum box system, can solve the problem that metal materials cannot be processed by laser, and achieve the effect of ensuring the quality of laser processing, simple software development, and long data transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

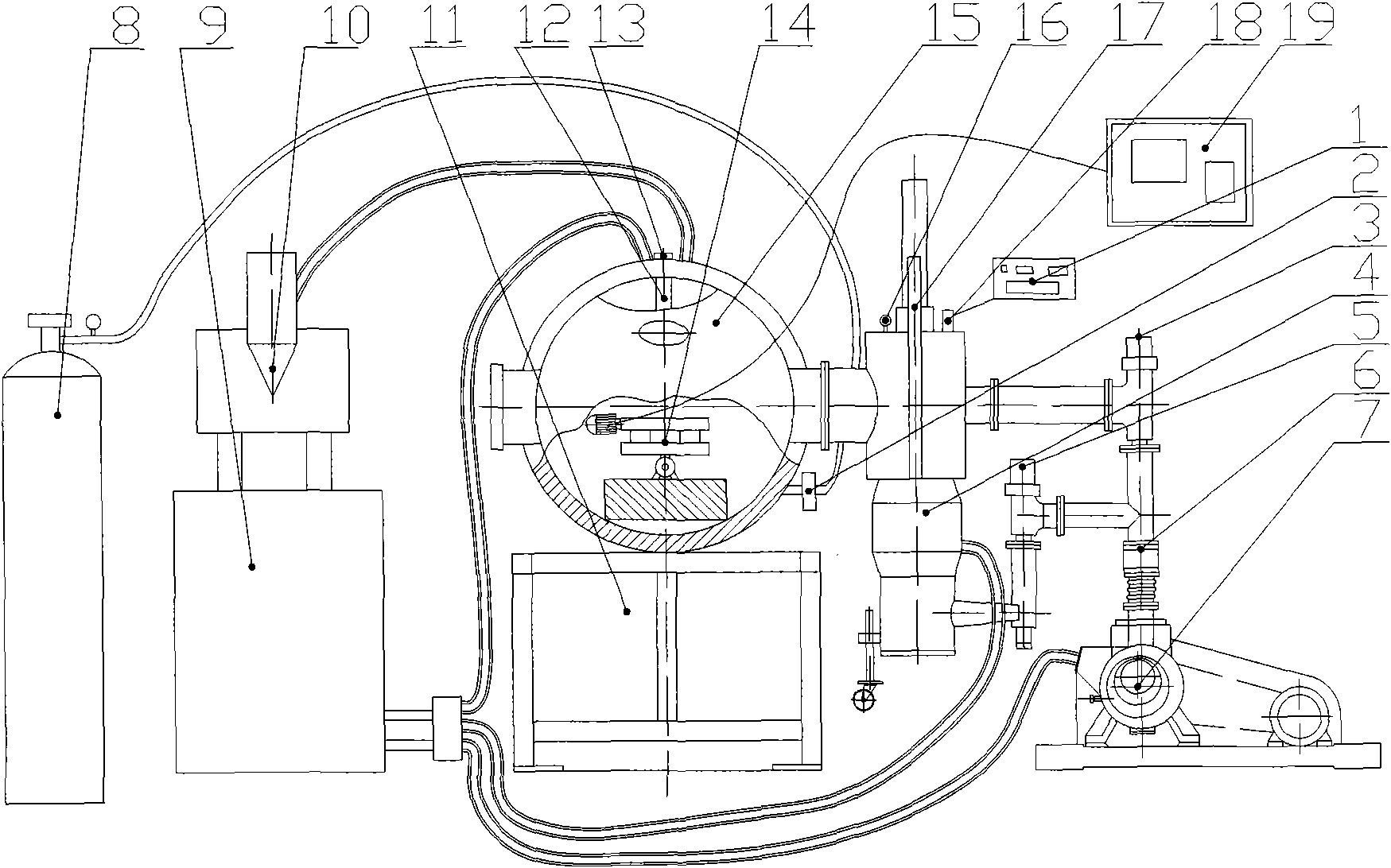

[0027] like figure 1 Shown: a vacuum box system for laser processing, mainly including a shielding gas system, a vacuum chamber 15, a vacuum acquisition system, a cooling system 9, a three-dimensional workbench 14, a powder feeding system, a computer control system 19 and an electric control system. The vacuum chamber 15 is fixed on the base 11 . The three-dimensional workbench 14 is fixed in the vacuum chamber 15 . The lens window assembly 13 is fixed on the upper end of the vacuum chamber 15 . The shielding gas system, the powder feeding system and the vacuum obtaining system are connected to the vacuum chamber 15 through hoses. The cooling system 9 is connected with the vacuum chamber 15 and the vacuum obtaining system through hoses. The computer control system 19 and the electric control system are connected with the vacuum chamber, the three-dimensional workbench, the powder feeding system and the vacuum obtaining system through electric wires. The electric control sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com