Micro-beam arc selective melting additive manufacturing method based on preset metal powder

A metal powder and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of unstable droplet transition, multiple forming, and inability to form, and achieve the effects of miniaturization of equipment, high forming precision, and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

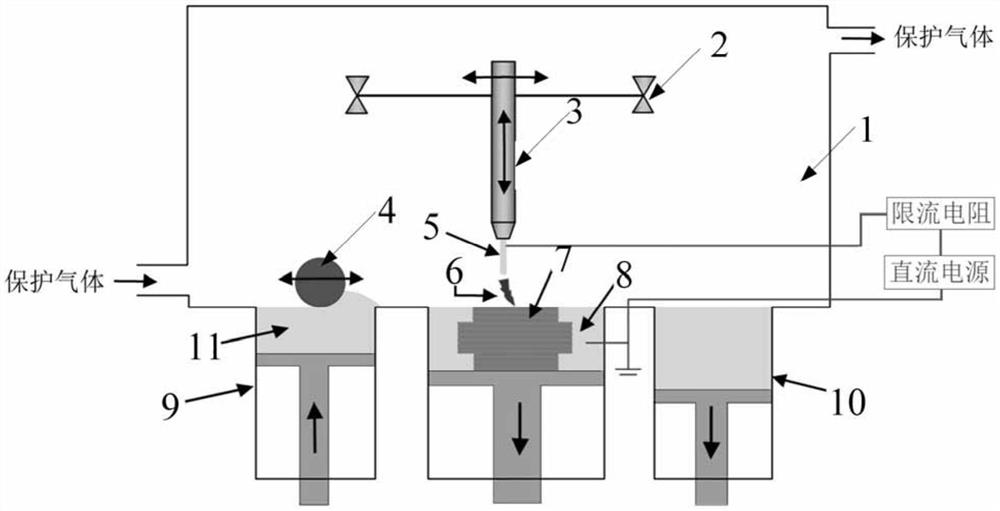

[0047] The micro-beam arc selective melting additive manufacturing method based on preset metal powder in this embodiment is realized based on an additive manufacturing device, such as figure 1As shown, the device includes a sealing chamber 1, an XY-axis scanning motion mechanism 2, a Z-axis servo feeding mechanism 3, a powder spreading roller 4, a tool electrode 5, a feeding chamber 9, a forming chamber 8, a collecting chamber 10, a DC power supply and Current limiting resistor;

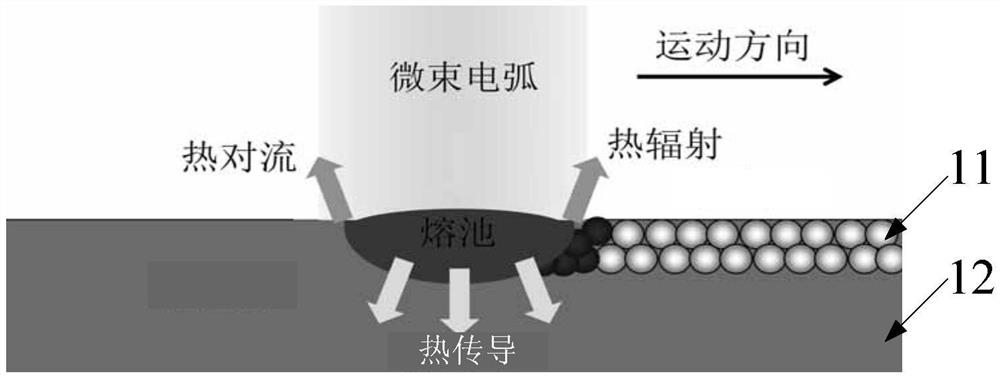

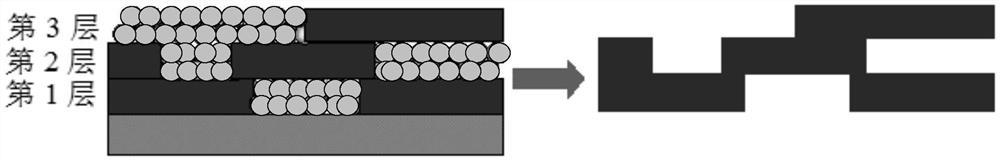

[0048] The bottom of the sealed chamber 1 is provided with a feeding chamber 9, a molding chamber 8 and a collection chamber 10 in turn, and the bottoms of the feeding chamber 9, the molding chamber 8 and the collection chamber 10 are respectively provided with a lifting mechanism, and the powder spreading pressure roller 4 is arranged on In the sealed chamber 1, the powder-spreading roller 4 pushes the metal powder 11 in the feeding chamber 9 into the molding chamber 8 to form a layer, and has a pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com